Clean energy future: New cheap and efficient electrode for splitting water

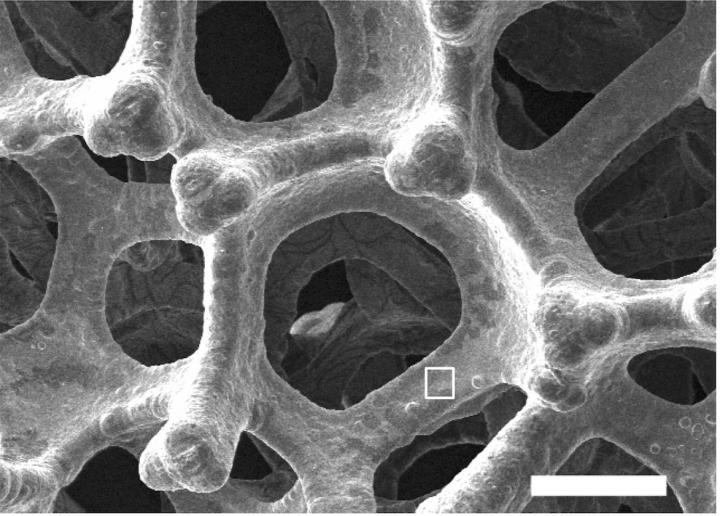

A scanning electron microscope image shows the porous structure of the nickel foam used to make UNSW Australia's inexpensive and efficient oxygen-producing electrode. The foam has holes in it about 200 micrometers across (Scale bar is 200 micrometers) Credit: UNSW Australia

“Our electrode is the most efficient oxygen-producing electrode in alkaline electrolytes reported to date, to the best of our knowledge,” says Associate Professor Chuan Zhao, of the UNSW School of Chemistry.

“It is inexpensive, sturdy and simple to make, and can potentially be scaled up for industrial application of water splitting.”

The research, by Associate Professor Zhao and Dr Xunyu Lu, is published in the journal Nature Communications.

Inefficient and costly oxygen-producing electrodes are one of the major barriers to the widespread commercial production of hydrogen by electrolysis, where the water is split into hydrogen and oxygen using an electrical current.

Unlike other water electrolysers that use precious metals as catalysts, the new UNSW electrode is made entirely from two non-precious and abundant metals – nickel and iron.

Commercially available nickel foam, which has holes in it about 200 micrometres across, or twice the diameter of a human hair, is electroplated with a highly active nickel-iron catalyst, which reduces the amount of costly electricity needed for the water-splitting to occur.

This ultra-thin layer of a nickel-iron composite also has tiny pores in it, about 50 nanometres across.

“The three-dimensional architecture of the electrode means it has an enormous surface area on which the oxygen evolution reaction can occur,” says Associate Professor Zhao.

“The larger bubbles of oxygen can escape easily through the big holes in the foam. As well, the smaller holes make the electrode surface 'wetter', so the bubbles do not stick to it, which is a common problem that makes electrodes less efficient.”

Hydrogen production is a rapidly growing industry, but the majority of hydrogen is still produced using fossils fuels such as natural gas, oil and coal, because this approach is still cheaper than electrolysis of water.

Hydrogen is a great fuel for powering mobile devices or vehicles, and storing electricity generated from renewable energy, such as solar.

“I think this electrode has great potential for the industrial-scale production of hydrogen. Our next goal is to understand the science behind it and to further improve its performance. Cleaner sources of fuel like hydrogen will be particularly important for reducing carbon dioxide emissions and solving the air pollution problems from the burning of fossil fuels such as coal,” says Associate Professor Zhao.

###

Media contacts:

Associate Professor Chuan Zhao: + 61(2) 9385 4645, chuan.zhao@unsw.edu.au

UNSW Science media officer: Deborah Smith + 61(2) 9385 7307, + 61 (0) 478 492 060, deborah.smith@unsw.edu.au

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…