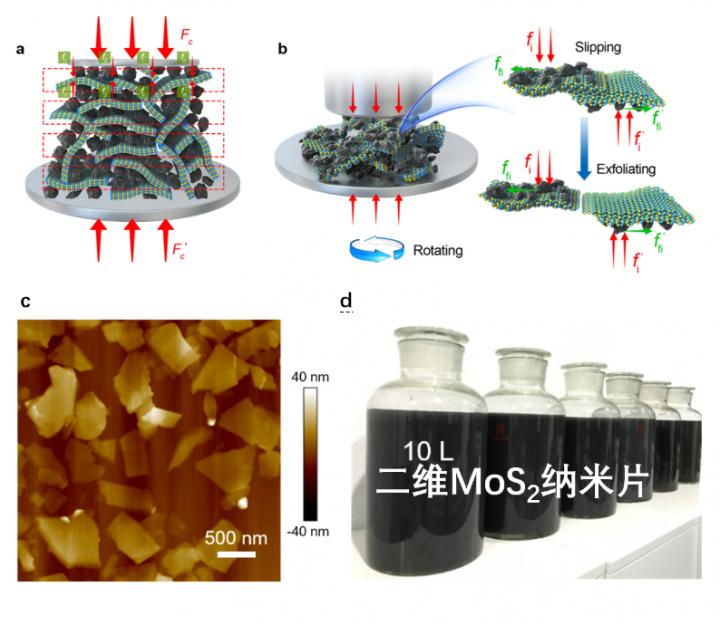

(a) Schematic of the decomposition of the macroscopic compressive forces Fc and Fc? into much smaller microscopic forces fi and fi? that were loaded onto the layer materials by force intermediates. (b) Exfoliation mechanism of layer materials. fi and fi? transfer to sliding frictional forces ffi and ffi? under the relative slipping of the intermediates and layer materials due to the rotation of the bottom container. (c) Atomic force microscopy image of 2D flakes. (d) Photos of several bottoms of 2D MoS2 flakes in aqueous solution.

Credit: ©Science China Press

In order to realize their commercial use, the prerequisite is large-scale production. Bottom-up strategies like chemical vapor deposition (CVD) and chemical synthesis have been extensively explored but only small quantities of 2D materials have been produced so far.

Another important strategy to obtain 2D materials is from a top-down path by exfoliating bulk layer materials to monolayer or few layer 2D materials, such as ball milling, liquid phase exfoliation, etc. It seems that top-down strategies are most likely to be scaled-up, however, they are only suitable for specific materials.

So far, only graphene and graphene oxide can be prepared at the tons level, while for other 2D materials, they still remain in the laboratory state because of the low yield. Therefore, it is necessary to develop a high-efficiency and low-cost preparation method of 2D materials to progress from the laboratory to our daily life.

The failure of solid lubricants is caused by the slip between layers of bulk materials, and the result of the slip is that the bulk materials will be peeled off into fewer layers.

Based on this understanding, in a new research article published in the Beijing-based National Science Review, the Low-Dimensional Materials and Devices lab led by Professor Hui-Ming Cheng and Professor Bilu Liu from Tsinghua University proposed an exfoliation technology which is named as interMediate-Assisted Grinding Exfoliation (iMAGE).

The key to this exfoliation technology is to use intermediate materials that increase the coefficient of friction of the mixture and effectively apply sliding frictional forces to the layer material, resulting in a dramatically increased exfoliation efficiency.

Considering the case of 2D h-BN, the production rate and energy consumption can reach 0.3 g h-1 and 3.01×106 J g-1, respectively, both of which are one to two orders of magnitude better than previous results.

The resulting exfoliated 2D h-BN flakes have an average thickness of 4 nm and an average lateral size of 1.2 μm. Besides, this iMAGE method has been extended to exfoliate a series of layer materials with different properties, including graphite, Bi2Te3, b-P, MoS2, TiOx, h-BN, and mica, covering 2D metals, semiconductors with different bandgaps, and insulators.

It is worth mentioning that, with the cooperation with the Luoyang Shenyu Molybdenum Co. Ltd., molybdenite concentrate, a naturally existing cheap and earth abundant mineral, was used as a demo for the industrial scale exfoliation production of 2D MoS2 flakes.

“This is the very first time that 2D materials other than graphene have been produced with a yield of more than 50% and a production rate of over 0.1g h-1. And an annual production capability of 2D h-BN is expected to be exceeding 10 tons by our iMAGE technology.”

Prof. Bilu Liu, one of the leading authors of this study, said, “Our iMAGE technology overcomes a main challenge in 2D materials, i.e., their mass production, and is expected to accelerate their commercialization in a wide range of applications in electronics, energy, and others.”

###

See the article:

Chi Zhang+, Junyang Tan+, Yikun Pan, Xingke Cai, Xiaolong Zou, Hui-Ming Cheng* and Bilu Liu*

Mass Production of Two-Dimensional Materials by Intermediate-Assisted Grinding Exfoliation

Natl Sci Rev 2019; doi: 10.1093/nsr/nwz156

https:/

The National Science Review is the first comprehensive scholarly journal released in English in China that is aimed at linking the country's rapidly advancing community of scientists with the global frontiers of science and technology. The journal also aims to shine a worldwide spotlight on scientific research advances across China.