Researchers at The University of Tokyo and Yokohama City University create elastic fluorescent crystals that reversibly change color when bent or deformed. This work may lead to the development of durable mechanical sensors that require little or no external power.

Credit: Institute of Industrial Science, The University of Tokyo

The ability to visualize forces can be very useful in many industries, particularly heavy manufacturing and shipping. For example, a color-changing material that shows where beams are being stressed would be great for construction companies.

However, such devices often work once and have to be replaced after being stretched. Materials that bounce back after being stretched or squeezed, like a rubber ball, are called elastic. But even these objects can suffer a permanent change of shape when stressed too much, in a process called plastic deformation.

Now, a team has introduced a new organic material that changes the color of its emitted fluorescence from green to red under mechanical stress, and bounces right back to its original configuration when this stress is removed.

“We called this property 'superelastochromism' because the color changes are due to completely reversible–that is, elastic–changes to the arrangements of molecules in the material,” says first author Toshiki Mutai.

Based on 7-chloro-2-(2?-hydroxyphenyl)imidazo[1,2-a]pyridine (7Cl), the crystals consist of molecules that can exist in two distinct configurations. In both states, a hydrogen atom is covalently bonded to an oxygen atom, and only weakly attracted to a nearby nitrogen atom.

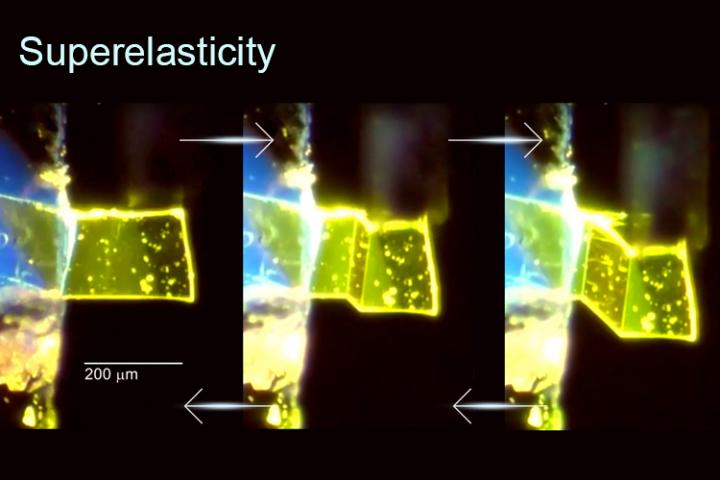

When the material is squeezed or bent, the molecular arrangement switches to the other configuration. This mechanically controlled phase transition alters the wavelengths of light the molecule will emit as fluorescence when excited by an external UV light source. The change is clearly apparent to the unaided eye as a shift in color from neon green to reddish orange.

“Chromatic changes in sensors are highly desirable, because they are easily seen and interpreted by people,” says senior author Satoshi Takamizawa. “If more precise measurements are needed, spectroscopy can be used to quantify the amount of stress.”

This work can help led to a wide range of “smart” material sensors. For example, one could be used to determine the time when mechanical stress is applied or removed.

###

The work is published in Nature Communications as “A superelastochromic crystal” (DOI:10.1038/s41467-020-15663-5)

About Institute of Industrial Science (IIS), the University of Tokyo

Institute of Industrial Science (IIS), the University of Tokyo is one of the largest university-attached research institutes in Japan.

More than 120 research laboratories, each headed by a faculty member, comprise IIS, with more than 1,000 members including approximately 300 staff and 700 students actively engaged in education and research. Our activities cover almost all the areas of engineering disciplines. Since its foundation in 1949, IIS has worked to bridge the huge gaps that exist between academic disciplines and real-world applications.