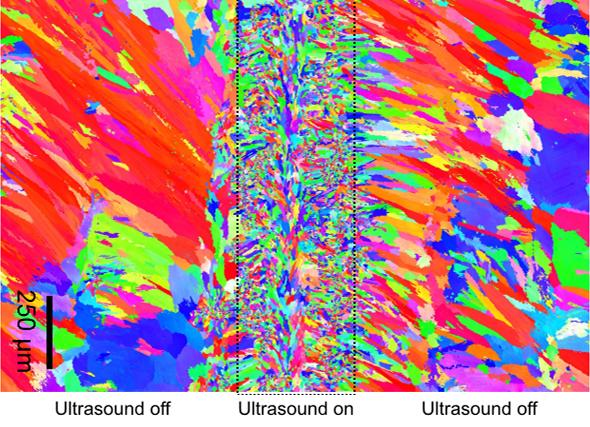

Visualisation of grain structure in 3D printed Inconel 625 achieved by turning the ultrasound on and off during printing.

Credit: RMIT University

A study just published in Nature Communications shows high frequency sound waves can have a significant impact on the inner micro-structure of 3D printed alloys, making them more consistent and stronger than those printed conventionally.

Lead author and PhD candidate from RMIT University's School of Engineering, Carmelo Todaro, said the promising results could inspire new forms of additive manufacturing.

“If you look at the microscopic structure of 3D printed alloys, they're often made up of large and elongated crystals,” Todaro explained.

“This can make them less acceptable for engineering applications due to their lower mechanical performance and increased tendency to crack during printing.”

“But the microscopic structure of the alloys we applied ultrasound to during printing looked markedly different: the alloy crystals were very fine and fully equiaxed, meaning they had formed equally in all directions throughout the entire printed metal part.”

Testing showed these parts had a 12% improvement in tensile strength and yield stress compared with those made through conventional additive manufacturing.

The team demonstrated their ultrasound approach using two major commercial grade alloys: a titanium alloy commonly used for aircraft parts and biomechanical implants, known as Ti-6Al-4V, and a nickel-based superalloy often used in marine and petroleum industries called Inconel 625.

By simply switching the ultrasound generator on and off during printing, the team also showed how specific parts of a 3D printed object can be made with different microscopic structures and compositions, useful for what's known as functional grading.

Study co-author and project supervisor, RMIT's Distinguished Professor Ma Qian, said he hoped their promising results would spark interest in specially designed ultrasound devices for metal 3D printing.

“Although we used a titanium alloy and a nickel-based superalloy, we expect that the method can be applicable to other commercial metals, such as stainless steels, aluminium alloys and cobalt alloys,” Qian said.

“We anticipate this technique can be scaled up to enable 3D printing of most industrially relevant metal alloys for higher performance structural parts or structurally graded alloys.”

###

The article 'Grain structure control during metal 3D printing by high-intensity ultrasound' is published in Nature Communications with DOI: 10.1038/s41467-019-13874-z

This research was conducted at RMIT University's Advanced Manufacturing Precinct and supported by an Australian Research Council Discovery Project grant.