Mobile Robots Transforming Aerospace Manufacturing Processes

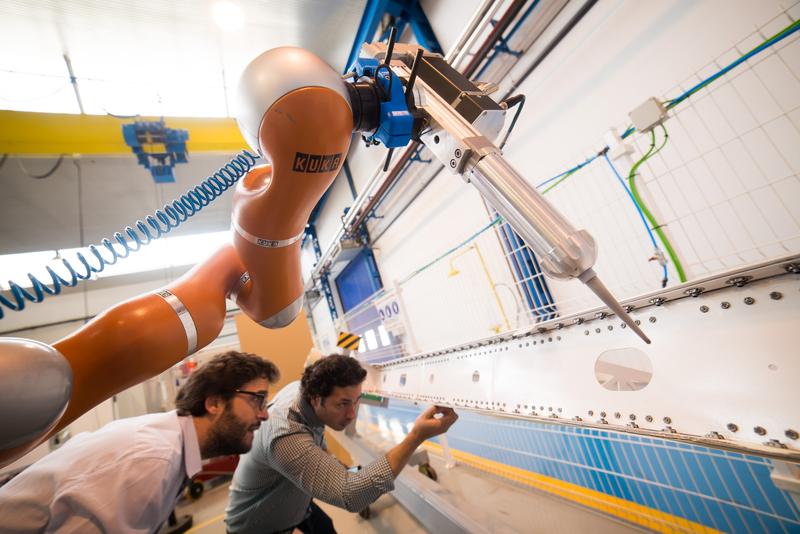

José Navarro from IDPSA and José Saenz from the Fraunhofer IFF examine how VALERI has applied sealant to an aircraft part.

picture: KUKA

Coordinated by the Fraunhofer Institute for Factory Operation and Automation IFF in Magdeburg, the experts specifically aimed to automate manufacturing jobs that can be hazardous to health or are extremely monotonous and physically strenuous.

They also want to have jobs with many steps that recur throughout the aircraft manufacturing process performed by one single mobile robot in the future. Robots will not replace skilled labor. Rather, they will simplify their work and assist them in their jobs.

Researchers in the VALERI project (Validation of Advanced, Collaborative Robotics for Industrial Applications) established the technical conditions for humans and robots to work next to each other. Taking the application of sealant to aircraft fuselages and the inspection of parts as model tasks, they demonstrated at Airbus DS facilities in Seville that protective barriers will no longer be needed in future manufacturing facilities.

Then, humans and robots will be working right next to each other, maybe even on the same part, and still act autonomously. The project partners added a second inspection sensor to the VALERI robot system to additionally demonstrate the flexibility of the system for use in other manufacturing industries, too. The experts are breaking new ground with VALERI, making their vision for human-robot collaboration and the aerospace industry reality and getting one step closer to Industry 4.0.

The industrial end-users Airbus DS and FACC, the industrial robotics manufacturer KUKA Robotics GmbH, systems integrator IDPSA, and the research partners PROFACTOR GmbH and PRODINTEC were involved in the VALERI project. The project was funded by the European Commission with € 3.6 million under FP7 “Factories of the Future”.

More Flexibility

Humans work on large parts in a stationary production cell in manufacturing. Over a period of days, several shifts of workers assemble and inspect the parts. Specialized, stationary robotic systems are not cost effective in such a manufacturing environment. That is supposed to change in the future: A mobile robot will be performing similar tasks at several workstations. This is why the VALERI system needs to be more flexible than traditional, stationary industrial robots.

Complex Challenges

The project focused on three model jobs: applying sealant along a groove, subsequently inspecting the sealant, and inspecting braided carbon parts. While the first two applications are closely related, the VALERI consortium selected a third application to demonstrate the system’s overall flexibility. The robot is able to change tools. Programming it to execute entirely new operations is done quickly and intuitively.

Individual Technologies, Highly Integrated System

At the outset of the project, KUKA modified an existing omniRob robot to have a reach suitable for the range of tasks planned. This included adding a rotatable linear axis atop the mobile platform, thus giving the robot twelve degrees of freedom and a reach comparable to that of a human. Such a hyper-redundant system necessitated coordinating all of its motions – real mobile manipulation – so that the VALERI robot could be programmed intuitively and could perform all of its tasks.

The researchers from the Fraunhofer IFF in Magdeburg developed tactile sensors and a camera-based workplace monitoring system as safety technologies for direct human-robot collaboration. The tactile sensors detect contact and the robot stops before biomechanical thresholds are reached. The researchers had determined the maximum allowable robot speeds beforehand.

These data are extremely important for the global robotics community – they will aid in the validation of collaborative robots with power and force limiting safeguards. What is more, the tactile sensors can be used for haptic interaction with the robot. User studies have confirmed that haptic interaction that essentially requires operators to give the robot a push in the direction it should move is very intuitive to use.

The workplace monitoring system consists of a time-of-flight camera combined with three stereo camera pairs. It tracks a tool’s movement and creates a virtual safeguarded zone around it. The robot stops if a human or object enters this safeguarded zone, thus preventing any collision.

The experts from IDPSA developed the tool that applies sealant and integrated it in the robot controller, thus making it possible to closely coordinate the application of sealant with the robot’s peed and orientation. Sealant is now applied along curved and flat trajectories significantly better.

The research organization Prodintec adapted and integrated a camera-based tool that localizes parts. The camera captures 3D point clouds and uses CAD matching-software to identify and localize parts. This enables VALERI to locate and work on parts, which are sometimes on rollers and not always in the same spot in the factory. The company Profactor developed and integrated two other tools, which the VALERI robot can use to inspect applied sealant and braided carbon parts.

The VALERI project has received funding by the European Union Seventh Framework Programme (FP7/2007-2013) under grant agreement number 314774.

http://www.iff.fraunhofer.de/en/business-units/robotic-systems/research/robotics… for more information on robots in manufacturing

http://www.valeri-project.eu/ – for more information on the VALERI-project