Exploring Additive Manufacturing: From Macro to Nano Innovations

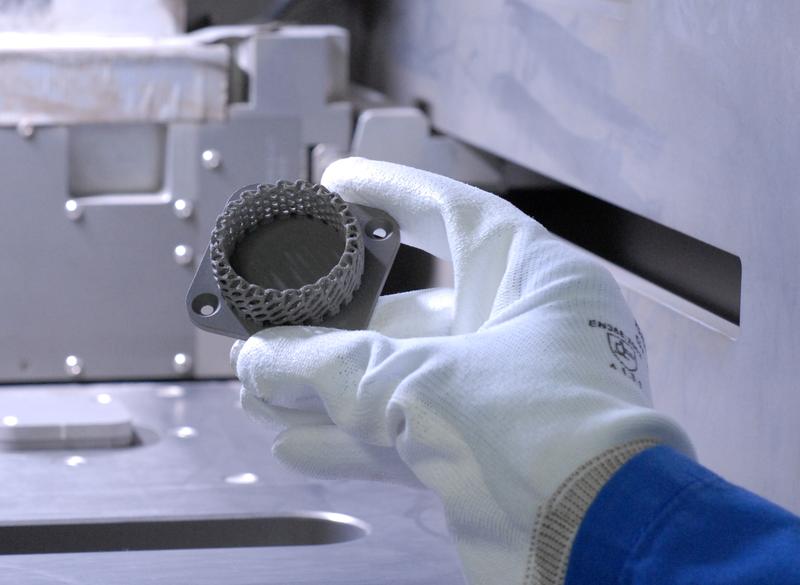

Magnesium part produced with selective laser micro melting.

Photo: LZH

The sky's the limit: laser deposition welding

Large amounts of material can be processed very quickly with additive manufacturing on the macro and XXL scale. Using wire-based deposition welding, scientists at the LZH are able to completely construct metal parts, or change finished parts.

The relatively slow deposition rates of laser-wire deposition welding can be significantly increased by using additional energy sources, such as arc lamps. At the moment, deposition rates of over 10 kg/h are possible. Curved surfaces can be treated using powder-based, laser deposition welding.

Special materials from macro to micro

Selective laser melting can be used to accurately and precisely manufacture small components made of metal. Using this processing method, the laser beam melts very fine metal powder, layer for layer. For structures with a resolution of less than 30 µm, selective laser micro-melting can be used. The LZH is researching for both methods the use of special materials such as magnesium or shape memory alloys such as nickel-titanium.

Microcomponents made of more than one material

Additional processes for the micrometer scale are stereolithography (SLT) and nozzle-based processes for metals and polymers. For both methods, the LZH can currently achieve lateral resolutions of 5 to 10 µm. It is possible to build up layers of different materials and to change the material within one layer.

From nanometer to centimeter

Two-photon-polymerization (2PP) can be used to manufacture micro- and nano-structured objects using direct laser printing. In comparison to most 3-D printing processes, strict layer by layer manufacturing is not necessary, and the laser can print objects in a polymer, both three-dimensionally and directly.

This technology is especially interesting because it is non-contact, and structure resolutions can be scaled on a wide range, from sub-100 nm to several micrometers. In the labs at the LZH, larger volumes up to the centimeter range can also be printed.