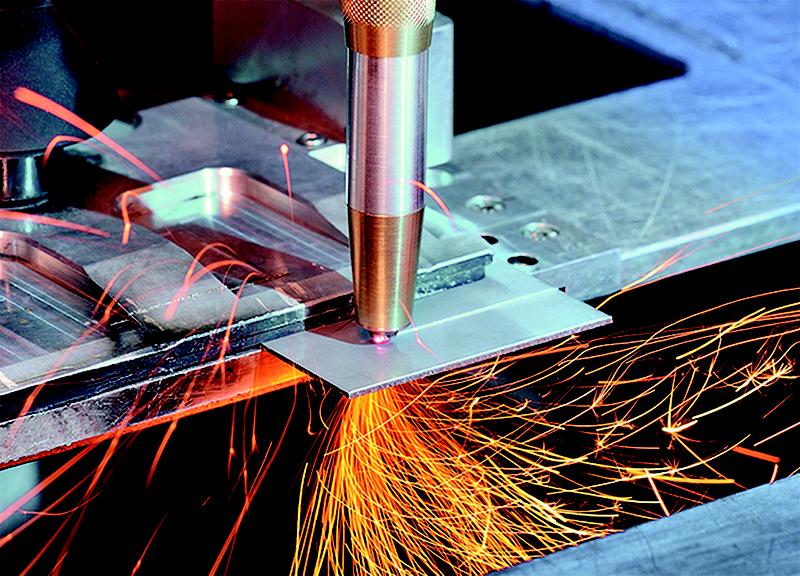

Image 1: This laser cutting head with diamond optics features built-in water cooling and shielding gas supply; diamond lenses reduce its weight by 90%.

© Fraunhofer ILT, Aachen, Germany

Photonics experts from around the world will make their annual pilgrimage to San Francisco in late January. Their destination is SPIE Photonics West, a symposium with an extensive program featuring more than 5,200 presentations and a major exhibition with some 1,300 companies.

Fraunhofer ILT will be there, as usual. The Aachen-based institute's forte is laser technology for industrial applications. Fraunhofer ILT’s spectrum is broad, ranging from beam source development and additive processes to Industry 4.0.

Diamond lenses for 90% lighter laser optics

ILT's researchers teamed up with Fraunhofer Institute for Applied Solid State Physics IAF in Freiburg and fellow Aachen-based Fraunhofer Institute for Production Technology IPT to develop a new laser optics with diamond lenses. Fraunhofer IAF optimized the production of monocrystalline diamonds, while Fraunhofer IPT worked on ultra-precision tools for machining diamond surfaces. Their efforts paid off: it is now possible to produce diamond substrates with diameters as wide as 10 mm.

Diamonds' refractive index is very high at 2.4. They also conduct heat remarkably well. These properties enable engineers to scale laser optics down to much smaller dimensions. The laser cutting head developed at the Fraunhofer ILT is 90% lighter than comparable conventional components with glass lenses.

The diamond lenses and a 1 kW fiber laser underwent an initial set of successful trials in 2017. This combination was able to cut 1.5 mm stainless steel without any difficulties. Now the team is working on an upgrade to achieve higher performance. Project Manager Martin Traub says, “Individual components have been tested for 2 kW, but we're particularly interested in 4 kW.”

New diode laser technology for energy-efficient materials processing

Fraunhofer ILT also wrapped up the BRIDLE project, an initiative to develop fiber-coupled diode lasers, in 2016. One of its objectives was to investigate laser diodes' dense wavelength coupling for demanding materials processing applications such as laser cutting. Researchers expect that it will not be long before diode laser-based beam sources provide the winning combination of optimum energy efficiency, very good beam characteristics and competitive manufacturing costs.

The team built a demonstrator that successfully coupled five wavelengths from different emitters on one bar into one 35 µm fiber. Its output power is 46 W, but various options allow for further scaling. Another system with around 800 W output from a fiber with a core diameter of 100 µm has also proven its merits in cutting tests.

FULAS – the platform for space-borne lasers

Fraunhofer ILT's experts have been working on laser systems for aerospace applications for many years. These efforts have culminated in the Future Laser System, or FULAS for short. Tomorrow's laser and optical systems for the aerospace industry will be built on the foundation of this universal platform.

FULAS not only features space-grade components; this platform also comes with semi-automated assembly technology. The FULAS demonstrator passed environmental qualification tests conducted in Airbus Defence and Space's climate chamber. Researchers are now developing and building the beam source for the MERLIN mission.

Fraunhofer ILT at Photonics West 2018

Fraunhofer ILT will set up shop in booth 4529-27 at the Photonics West Exhibition and will give several presentations. For more information: www.ilt.fraunhofer.de/en/fairs-and-events/fairs/photonics-west-2018.html

Contact

Dipl.-Ing. Dipl.-Wirt.Ing. Martin Traub

Group Manager Optics Design and Diode Lasers

Telephone +49 241 8906-342

martin.traub@ilt.fraunhofer.de

http://www.ilt.fraunhofer.de/en

https://www.ilt.fraunhofer.de/en/fairs-and-events/fairs/photonics-west-2018.html