- Simotics XP 1MB1 motors – now approved for use with Sinamics converters in potentially explosive atmospheres

- Energy-efficient operation with 1MB1 motors possible in the 0.09 to 200 kilowatt output range

- Motor operating data determined using Sizer engineering tool for Siemens drives

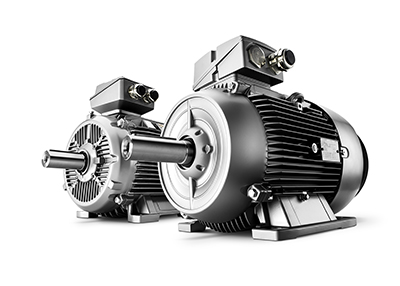

An extension to the EC Type Examination Certificate has opened up new scope for the IMB1 motor series, which is now approved for both mains and converter-fed operation. The Sizer engineering tool for Siemens drives can be used to ascertain the operating data of Simotics XP 1MB1 motors used with the approved Sinamics converters. Energy-efficient, reliable converter-fed motor operation is possible in an output range of 0.09 to 200 kilowatts.

Motors used in potentially explosive environments such as those encountered in the chemical and petrochemical, oil and gas industries have to comply with IEC EN 60079 standards designed to protect human life, machines and the environment. With its Simotics XP motor series, Siemens offers a range of explosion-proof motors for use in potentially explosive gas and dust-laden atmospheres. These motors are available in protection types Ex nA, Ex tb and Ex tc for use in zones 2, 21 and 22.

Used in combination with Sinamics converters, the Simotics XP 1MB1 motors form a pre-tested and ideally coordinated Integrated Drive System (IDS). Benefits for the user include minimal installation costs, high availability and economical plant operation.

The explosion-proof Simotics XP motors are particularly suited for use in the chemical and petrochemical industry. They are also used in the oil and gas industry, the woodworking and plastics processing industries and in agriculture. The motors are certified in compliance with the European Directive 94/9/EC (ATEX), IECEx (required for example in Australia) und EAC (Eurasia).

For further information on the subject of Simotics, please see www.siemens.com/simotics-xp

Siemens AG (Berlin and Munich) is a global technology powerhouse that has stood for engineering excellence, innovation, quality, reliability and internationality for more than 165 years. The company is active in more than 200 countries, focusing on the areas of electrification, automation and digitalization. One of the world's largest producers of energy-efficient, resource-saving technologies, Siemens is No. 1 in offshore wind turbine construction, a leading supplier of gas and steam turbines for power generation, a major provider of power transmission solutions and a pioneer in infrastructure solutions as well as automation, drive and software solutions for industry. The company is also a leading provider of medical imaging equipment – such as computed tomography and magnetic resonance imaging systems – and a leader in laboratory diagnostics as well as clinical IT. In fiscal 2015, which ended on September 30, 2015, Siemens generated revenue of €75.6 billion and net income of €7.4 billion. At the end of September 2015, the company had around 348,000 employees worldwide.

Further information is available on the Internet at www.siemens.com

Reference Number: PR2015110077PDEN

Contact

Mr. Stefan Rauscher

Process Industries and Drives Division

Siemens AG

Gleiwitzer Str. 555

90475 Nuremberg

Germany

Tel: +49 (911) 895-7952

Stefan.Rauscher@siemens.com