Newly developed elastomers and use of the nodular cast iron casting method allow the Flender N-Bipex claw coupling to achieve improved and, most importantly, temperature-independent performance alongside a high degree of freedom for shaping the cams.

- Improved service life due to optimized cam and elastomer geometry combined with high-grade materials

- Torque range increased by up to 20 percent

- Newly developed elastomers enable application in temperature ranges from -50°C to +100°C with full utilization of nominal torques

- Suitable for applications in the chemical, environmental engineering and steel industries

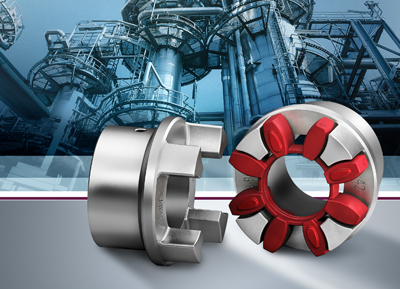

Siemens is extending its comprehensive coupling portfolio to include a new elastic claw coupling, the Flender N-Bipex, which will be available in ten sizes made of high-quality nodular cast iron. An optimized cam geometry and newly developed elastomers have meant a major improvement to the service life of the N-Bipex in comparison to standard couplings available in the marketplace.

Depending on the size, torque has been increased by between ten and 20 percent over previous solutions. The new elastomers are available in three different shore hardnesses, and allow the couplings to be used across a temperature range of -50° C to +100 °C without compromising nominal torque.

Flender N-Bipex couplings are used predominantly in connection with hydraulic systems and geared motors, meaning that they are found across the whole of the machine building sector, with applications throughout the chemical, environmental engineering and steel industries.

The casting method used increases the degree of freedom for shaping the cams. This added scope enables the contour to be designed to ensure optimum engagement of the load flank surfaces. The decisive factor here is that the adjacent cam ring made of high-grade polyurethane has the facility for sufficient load-dependent deformation, while remaining in its designated position under all conditions. This results in a marked reduction in wear coupled with increased performance.

The degree of resilience to forced rupture and the maximum admissible speeds achievable with nodular cast iron couplings are far superior to those of grey cast iron couplings, and are comparable to their steel counterparts.

The newly developed elastomers used for the Flender N-Bipex are designed for high performance. They are capable of withstanding dynamic loads across a very wide temperature range without restriction. The material used offers excellent compressive strength, wear resistance, dimensional stability and ductility.

For more information on couplings, please go to www.siemens.com/couplings

Siemens AG (Berlin and Munich) is a global technology powerhouse that has stood for engineering excellence, innovation, quality, reliability and internationality for more than 165 years. The company is active in more than 200 countries, focusing on the areas of electrification, automation and digitalization. One of the world's largest producers of energy-efficient, resource-saving technologies, Siemens is No. 1 in offshore wind turbine construction, a leading supplier of combined cycle turbines for power generation, a major provider of power transmission solutions and a pioneer in infrastructure solutions as well as automation, drive and software solutions for industry. The company is also a leading provider of medical imaging equipment – such as computed tomography and magnetic resonance imaging systems – and a leader in laboratory diagnostics as well as clinical IT. In fiscal 2014, which ended on September 30, 2014, Siemens generated revenue from continuing operations of €71.9 billion and net income of €5.5 billion. At the end of September 2014, the company had around 343,000 employees worldwide on a continuing basis.

Further information is available on the Internet at www.siemens.com

Reference Number: PR2015040184PDEN

Contact

Ms. Ines Giovannini

Process Industries and Drives Division

Siemens AG

Gleiwitzer Str. 555

90475 Nuremberg

Germany

Tel: +49 (911) 895-7946

ines.giovannini@siemens.com