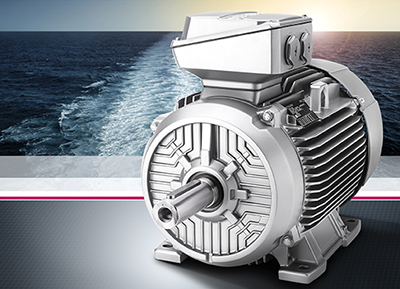

With Simotics DP, Siemens is offering below-deck marine motors based on the proven 1LE1 platform. With an aluminum or grey cast iron housing, as a standard version or in a special version for potentially explosive areas, these motors are available in a wide spectrum of outputs ranging from 0.18 to 200 kW. Their capacity for operation at up to 500 volts (V) at the converter allows these line motors to also form part of Integrated Drive Systems, and so enhancing the efficiency of the entire drive train.

Marine motors do not fall within the scope of the European Motor Directive 640/2009, which defines the currently valid eco design regulations for electric motors in industrial applications. Despite this, with its Simotics DP marine motors portfolio and the option of individual efficiency class selection from IE1 to IE4, Siemens is still offering users enormous scope for energy saving.

The absence of jumps in the shaft height between the efficiency classes IE1 and IE4 and the different outputs available make for significantly simplified upgrading or modernization of overall systems, providing the assurance of a secure high-level investment over the long term. The integrated Simotics DP motor product spectrum with outputs ranging from 0.18 to 200 kW is based on the familiar 1LE1 platform, and also includes motors for potentially explosive atmospheres (ATEX motors).

The motors are available with an aluminum or grey cast iron housing. The output range varies depending on the version: motors in an aluminum housing range from 0.37 to 45 kW, in a grey cast iron housing from 0.18 to 200 kW, and in the explosion-proof version for zones 2/21/22 from 0.37 to 200 kW. All versions are pre-certified for use below deck by the ships classification and certification bodies DNV, GL, BV, LRS, RS, KR, ABS and RINA.

This saves time for the customer primarily during planning and acceptance of the completed ship. In terms of planning and its flexibility, the user also benefits from the availability of the motors in both a line variant and for operation at a converter. Used in combination with a Sinamics frequency converter, the Simotics DP motor creates an Integrated Drive System (IDS), so additionally increasing the energy efficiency of the drive independently of the energy efficiency class of the motor itself.

The motors are used predominantly in shipbuilding applications, in ship compressors, feed pumps and winches. They are also used for port cranes and hydraulic pumps mounted on platforms.

As pre-certified Simotics DP marine motors are available in a choice of efficiency classes from IE1 to IE4, customers are able to benefit from enormous energy saving potential. The different versions and output ranges are designed to comply with widely differing requirements.

For further information on Simotics, please see www.siemens.com/simotics-dp

Siemens AG (Berlin and Munich) is a global technology powerhouse that has stood for engineering excellence, innovation, quality, reliability and internationality for more than 165 years. The company is active in more than 200 countries, focusing on the areas of electrification, automation and digitalization. One of the world's largest producers of energy-efficient, resource-saving technologies, Siemens is No. 1 in offshore wind turbine construction, a leading supplier of combined cycle turbines for power generation, a major provider of power transmission solutions and a pioneer in infrastructure solutions as well as automation, drive and software solutions for industry. The company is also a leading provider of medical imaging equipment – such as computed tomography and magnetic resonance imaging systems – and a leader in laboratory diagnostics as well as clinical IT. In fiscal 2014, which ended on September 30, 2014, Siemens generated revenue from continuing operations of €71.9 billion and net income of €5.5 billion. At the end of September 2014, the company had around 343,000 employees worldwide on a continuing basis.

Further information is available on the Internet at www.siemens.com

Reference Number: PR2015040163PDEN

Contact

Mr. Stefan Rauscher

Process Industries and Drives Division

Siemens AG

Tel: +49 (911) 895-7952

stefan.rauscher@siemens.com