- Dynamic motor for large machine tools

- Geared motor for auxiliary units such as pallet changers and chip conveyors

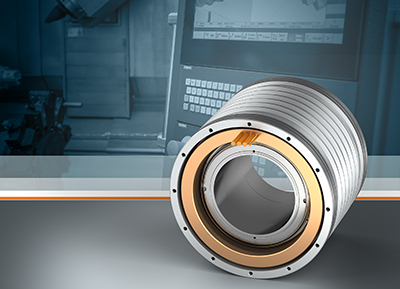

- High-torque spindle motors for heavy machinery

- Flexible segment motor for rotary tables and spindles

Siemens is unveiling numerous electric motors for use in machine tools. Covering a wide range of applications and offering outstanding torque, the new developments include the Simotics S-1FT7 compact synchronous servomotor with shaft height 132 as well as the Simotics S-1FG1 servo geared motor, which is available in a variety of models. Other innovations being presented are the powerful Simotics M-1FE2 built-in motor in size 180 and high-torque segment motors for use in large rotary tables and spindles.

Despite its compact size, the naturally cooled Simotics S1FT7 servomotor with shaft height 132 features a higher torque and consumes less power than previous models. The servomotor provides 90 to 170 newton meters (Nm) of torque depending on its length, making it especially suitable for large machine tools. With its new Simotics S-1FG1 servo geared motors, Siemens is expanding its motor portfolio for machine tools. The four types of gears and different gear ratios enable users to select the ideal configuration to meet their needs. Due to its superior energy efficiency and flexible torque ratio, the servo geared motor is especially suitable for use with auxiliary units such as pallet changers, chip conveyors, and feeder units.

The Simotics M-1FE2 built-in motor in size 180 has been designed for machining larger workpieces. The use of permanent magnets allows the spindle motor to achieve a particularly high torque density. With its high performance and internal diameter of 200 millimeters, the Simotics M-1FE2 is also suitable for use in large turning and milling centers as well as for sophisticated machining processes. Siemens also offers Simotics T-1FW68 high-performance segment motors. With a high torque of up to 1 million Nm, these direct drives can handle large to very large diameters. The segment motors allow for flexible configuration and can also be operated with a smaller number of stator segments.

Further information about servomotors is available at

www.siemens.com/motioncontrol

Further information about Siemens at the EMO 2015 is available at

www.siemens.com/emo

Additional press releases about Siemens innovations at the EMO 2015 are available at www.siemens.com/press/emo2015

Siemens AG (Berlin and Munich) is a global technology powerhouse that has stood for engineering excellence, innovation, quality, reliability and internationality for more than 165 years. The company is active in more than 200 countries, focusing on the areas of electrification, automation and digitization. One of the world's largest producers of energy-efficient, resource-saving technologies, Siemens is No. 1 in offshore wind turbine construction, a leading supplier of combined cycle turbines for power generation, a major provider of power transmission solutions and a pioneer in infrastructure solutions as well as automation, drive and software solutions for industry. The company is also a leading provider of medical imaging equipment – such as computed tomography and magnetic resonance imaging systems – and a leader in laboratory diagnostics as well as clinical IT. In the fiscal year 2014, which ended on September 30, 2014, Siemens generated revenue from continuing operations of €71.9 billion and net income of €5.5 billion. At the end of September 2014, the company had around 343,000 employees worldwide on a continuing basis.

Further information is available online at www.siemens.com

Reference Number: PR2015100006DFEN

Contact

Mr. Peter Jefimiec

Digital Factory Division

Siemens AG

Gleiwitzer Str. 555

90475 Nuremberg

Germany

Tel: +49 (911) 895-7975

peter.jefimiec@siemens.com