- Siemens drives forward the electrification, automation and digitalization of industrial processes

- Comprehensive presentation of the Siemens portfolio covering industrial software, automation and drive technology as well as services

- Digital Enterprise, focus on two key exhibition highlights and nine highlight topics

- Wide range of new products and solutions

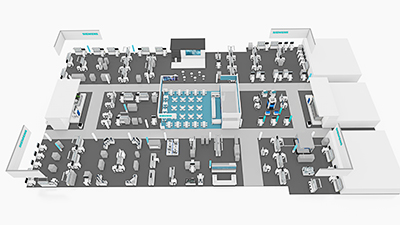

At this year's SPS IP Drives, Siemens will be pointing the way towards the digital future of industry under the banner “On the way to Industrie 4.0 – Driving the Digital Enterprise”. In Hall 11 (Frankenhalle), which will be given over entirely to Siemens, the company will be providing a comprehensive overview of its achievements as a leading global expert in driving forward developments in the electrification, automation and digitalization of industrial processes. Visitors may look forward to an array of product innovations across the fields of industrial software, automation and drive technology as well as services.

The thematic focus of the Siemens presentation in Hall 11 will be on the interaction between hardware, software and services along the entire industrial value chain, with a broad selection of exhibition highlights, product innovations and graphically illustrated application examples taken from producing companies clearly pointing the way to the Digital Enterprise of the future.

As the central exhibition highlight at the booth, Siemens will be showcasing the four pillars needed for the digital transformation of industrial processes: software, communication solutions, safety concepts and solutions as well as digital services.

“Our aim is to enhance the competitive standing of our customers and to help them make their production faster, more flexible and smarter,” said Heinz Eisenbeiss, Booth Manager at the SPS IPC Drives, speaking at a pre-fair press conference. “We are currently in a phase marked by the rapid advance of classical automation technology under the growing influence of digitalization, which is at the core of the Industrie 4.0 vision. We have deliberately reflected this in the Siemens booth slogan: On the way to Industrie 4.0 – Driving the Digital Enterprise.”

Confirming that all the core elements needed to enable customer investment in future-proof solutions for the gradual implementation of Industrie 4.0 already exist within the Siemens portfolio, Eisenbeiss added: “A visit to the Siemens booth can provide invaluable impetus towards achieving this goal”.

Next to the Digital Enterprise presentation in the center of the booth, two additional exhibition highlights will be given special prominence in the form of graphically presented application examples and practically-based solutions featuring the electrification, automation and digitalization of industrial processes.

The first of these is a multi-carrier system for packaging and filling machines developed in association with Festo. The simulation and downstream engineering using the TIA Portal (Totally Integrated Automation) permits the highly flexible transport of goods, enabling maximum individualization right down to batch size one. By linking to the cloud, all the production data generated by this machine can be seamlessly tracked and monitored live while in operation. With this capability, this exhibit is a representative example of digitalization in machine building from the engineering stage through to operation.

The second exhibition highlight illustrates how electrical power distribution is integrated into digital industrial processes in practical operation today. Using the model of a Sivacon sicube 8MF1 series control cabinet, visitors experience how a “digital twin” unites virtual control cabinet engineering with real production automation.

The integration of electrical power distribution into digital environments takes place here on three levels: into automated engineering processes with an extensive spectrum of software and data, into industrial automation through devices and open interfaces with communication capability, and finally into integrated energy efficiency concepts using systems, components and software for energy data measurement.

The spatial layout of the Siemens booth is supplemented by nine highlight topics given special prominence:

The Teamcenter software is a central knowledge platform bringing together product and process information. This supports cooperation between product engineering and production teams in reaching smarter planning decisions. Version 11 offers new features for the entire portfolio designed to enhance productivity, improve performance and drive down costs.

The Siemens Cloud for Industry in an open cloud platform to visualize and analyze data from the industrial sector. This data is the basis for services offered by Siemens and third party suppliers. It can be used for instance to run predictive maintenance as well as asset and energy data management. The new Connector Box enables simple and safe collection and transfer of machine and plant data into the Siemens Cloud for Industry.

The Engineering Framework TIA Portal is pivotal to leveraging the full performance potential of Totally Integrated Automation. The software is used to optimize all operating, machine and process sequences.

In the field of Telecontrol, Siemens will be showcasing the RTU303C, a remote terminal unit (RTU) for wireless monitoring of plants and systems. Working independently of the power supply network, the new RTU is used to monitor pumping stations, water storage facilities, irrigation systems and tank filling levels – for industries ranging from water and wastewater through agriculture to asset tracking in industrial environments.

To enable data management in the field of power distribution, TIP (Totally Integrated Power) makes available components with communication capability for power distribution systems. These support industrial automation and digitalization along the entire value chain, generating vital transparency for digital factories across all plant statuses and consumption values, so providing the basis for efficient, reliable production processes.

The new Simotics S-1FG1 servo geared motor with finely graduated transmission ratios and the Sinamics S120 converter with a wide array of technology functions and innovated power modules provide a flexible new servo drive system for challenging applications. Consistent integration into Totally Integrated Automation simplifies project engineering and commissioning.

Sirius ACT is a modular, highly rugged and durable system of IP69K protection rated pushbuttons and signaling devices. Featuring a contemporary selection of design lines, this extensive product portfolio is made in high-grade real metal and plastic. Particular benefits to note are an intuitive selection system using an online configurator, installation with 100% twist prevention and innovative snap-on concept.

Using the example of the complex system used by a paper producer involving a large number of individual drives, Siemens illustrates how customers benefit from an integrated, highly efficient and coordinated IDS (Integrated Drive System) – from the converter through the motor to the gear unit.

The new release 9.0 of the Simatic Process Device Manager enables plant-wide access to all field devices over the Internet Explorer, with secure server-client communication. Commissioning and service times have been significantly reduced by data export from the engineering station to individual PDM servers, and through improved user convenience with structured device connection point information. The connection of devices is also more efficient than previously due to high-quality device integration complete with syntax and semantic check.

In addition to the two exhibition highlights and nine booth highlight topics featured at the show, visitors to the Siemens booth at this year's SPS IPC Drives may also look forward to an array of other product innovations:

These include Bipex-S und Sipex backlash-free Flender couplings designed for extreme positioning accuracy. These are intended for use in machine tools and other production machinery, as well as in automation technology. The elastomer Bipex-S coupling is suitable for applications at risk from vibrations and impacts, while the torsionally rigid metal bellows coupling Sipex excels in angle preserving torque transmission.

The Sitop PSU8600 power supply system has been extended to include three new compact basic devices, two buffer modules with ultracaps as energy storage systems and new functions. Examples include an extended output voltage range from 5 to 28 volts, saving the need for supplementary power supplies, and an extended buffering time in case of power failure of up to 20 seconds.

The output of Sinamics DCP DC/DC converter for industry and smart grid applications has been extended from 30 to 120kW. The bi-directional DC/DC converter can be used to charge and discharge batteries. The device output is scalable up to 120kW, allowing it to be ideally adjusted to the relevant industrial or smart grid application.

The 400 volt versions of Sinamics G120P Cabinet frequency converter for pump, ventilator and compressor applications have been extended in output to 560 kilowatts. The rugged design of the ready-to-connect cabinet device allows it to be used in harsh industrial environments. It comes with an outstanding efficiency of 98 percent, application-specific energy saving functions and a wide choice of options. Time spent on engineering is reduced by integrated functions for pump, ventilator and compressor applications.

The 7KT/7KM PAC measuring devices create the basis for an in-house energy management system with full ISO 50001 compliance. In addition to the previously possible parameters, the devices are now also able to analyze power supply quality in commercial and industrial applications. They are able to check, for instance, whether the infeed energy quality complies with the contractually agreed standard or to ensure that machines and plants are functioning reliably around the world.

The task of 3VA compact circuit breakers is to ensure failsafe, high-availability production processes. There are new variants available for the protection of motors and starter combinations. Easy to configure using the new time-current characteristic Elisa, the new device variants simplify system planning and offer cost and space benefits in the control cabinet.

This press release, a recording of the Press Conference dated October 8, 2015 and other press information and pictures are available from: www.siemens.com/press/sps2015

More information on the subject of SPS IPC Drives 2015 is available at http://www.siemens.com/sps-fair

Siemens AG (Berlin and Munich) is a global technology powerhouse that has stood for engineering excellence, innovation, quality, reliability and internationality for more than 165 years. The company is active in more than 200 countries, focusing on the areas of electrification, automation and digitalization. One of the world's largest producers of energy-efficient, resource-saving technologies, Siemens is No. 1 in offshore wind turbine construction, a leading supplier of combined cycle turbines for power generation, a major provider of power transmission solutions and a pioneer in infrastructure solutions as well as automation, drive and software solutions for industry. The company is also a leading provider of medical imaging equipment – such as computed tomography and magnetic resonance imaging systems – and a leader in laboratory diagnostics as well as clinical IT. In fiscal 2014, which ended on September 30, 2014, Siemens generated revenue from continuing operations of €71.9 billion and net income of €5.5 billion. At the end of September 2014, the company had around 343,000 employees worldwide on a continuing basis.

Further information is available on the Internet at www.siemens.com

Reference Number: PR2015100009DFEN

Contact

Mr. Gerhard Stauss

Digital Factory Division

Siemens AG

Gleiwitzer Str. 555

90475 Nuremberg

Germany

Tel: +49 (911) 895-7945

gerhard.stauss@siemens.com