From Micro-Structures to Shipbuilding: Laser Technology at the Hannover Messe 2013

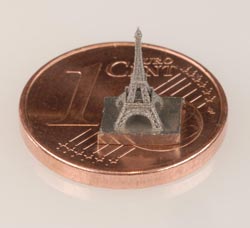

The miniature Eiffel tower (selective laser melting) can be seen at the LZH exhibition at this year’s Hannover Messe 2013<br>

This year, the LZH will be exhibiting innovative developments and applications in the fields of “Laser-based Manufacturing Technologies” and “Laser Precision Processing”.

Laser Precision Processing

An interesting example of laser precision processing is strain gauge sensors, which can provide exact measurements of strain and stresses in machines, bearings or motors. Since sensors are subject to rough environmental conditions such as high temperature change and mechanical and chemical stresses, they must be extremely robust. Conventional sensors are manufactured on foils or thin films, which are then affixed to the machines using adhesives, and unfortunately, the adhesives are sensitive to the rough conditions in machines or motors. Laser technology can overcome this limitation by structuring strain gauges directly on the surface of a component. These sensors are extremely robust and can even be placed on complex components with cylindrical, spherical or free-form shapes.

Further fair exhibits in the field of laser precision processing are laser structured surfaces which are highly water repellent (superhydrophobic), or solar cells which provide higher efficiency and energy output, due to laser processing.

Laser-based Manufacturing Technologies

Laser-based manufacturing technologies play an important role not only in production, but also in the research work being done at the LZH. Research topics range from using selective laser melting to generate tiny metal components up to welding 23 mm thick steel sheets, as used in shipbuilding or pipeline construction.

A good example illustrating the diversity of the tool „laser“ can be seen in laser processing of the light weight material CFRP (carbon fiber reinforced plastics), which is being used more and more in modern aviation applications. CFRP can be cut, drilled, structured and ablated using the laser, and it is even possible to weld plastics to CFRP components.

Another field for “laser lightweight construction” can be found in shipbuilding. The weight of large sized units can be cut in half by using laser welded sandwich material, steel sheets with an aluminum foam core. These lightweight steel-aluminum structures are difficult to weld, as cracks in the welding seams must be avoided, and a zero gap is required. LZH researchers, together with their project partners, could successfully laser weld ship structures made of Fe/Al sandwich materials for Blohm + Voss Naval GmbH in Emden, Germany. The results can be seen at the Hannover Messe.

Further information is available at www.lzh.de.

Visit our exhibition (Hall 17, Stand E 67) at the Hannover Messe 2013 (April 8th to 12th, 2013).

Contact:

Laser Zentrum Hannover e.V.

Michael Botts

Hollerithallee 8

D-30419 Hannover, Germany

Tel.: +49 511 2788-151

Fax: +49 511 2788-100

E-Mail: m.botts@lzh.de

The Laser Zentrum Hannover e.V. (LZH) carries out research and development in the field of laser technology and is supported by the Ministry of Economic Affairs, Labour and Transport of the State of Lower Saxony (Niedersächsisches Ministerium für Wirtschaft, Arbeit und Verkehr).

Media Contact

More Information:

http://www.lzh.deAll latest news from the category: HANNOVER MESSE

Newest articles

A new way of entangling light and sound

For a wide variety of emerging quantum technologies, such as secure quantum communications and quantum computing, quantum entanglement is a prerequisite. Scientists at the Max-Planck-Institute for the Science of Light…

Telescope for NASA’s Roman Mission complete, delivered to Goddard

NASA’s Nancy Grace Roman Space Telescope is one giant step closer to unlocking the mysteries of the universe. The mission has now received its final major delivery: the Optical Telescope…

Sensitive ceramics for soft robotics

Most people think of coffee cups, bathroom tiles or flower pots when they hear the word “ceramic”. Not so Frank Clemens. For the research group leader in Empa’s Laboratory for…