Sustainability is our Focus – LZH at the Hannover Messe 2014

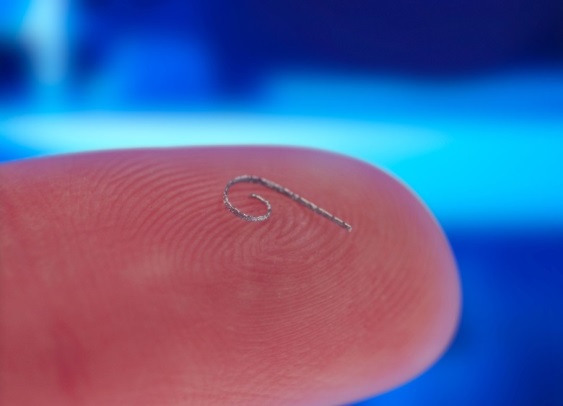

Laser additive manufacturing at the Hannover Messe: Cochlea implant made using SLµM. (© LZH)

The LZH is presenting at this year’s Hannover Messe, under the theme of “Sustainability is our Focus – Laser-based Production Cycles”, how laser technology can save energy and/or material during production, processing and repair and recycling.

Manufacturing: Production “out of the blue”

Laser Additive Manufacturing (LAM) can be used to produce individual workpieces in only one step. The left over material can usually be used for new production cycles. Using special materials is in particular interesting for the biomedical field. Bioresorbable magnesium implants and micro-actuators made of shape memory alloys can be used for new healing approaches. Polymer-workpieces with high resolutions make prototypes and small series production of tools and special machines possible. Fair visitors can see how an LAM unit functions, which materials can be used, and what the finished workpieces can be used for.

Processing: Saving Time, Processing Steps and Raw Materials

Hybrid welding can be used for more precise and faster processing of metal workpieces. From pipeline building to coating of tools, laser based processes save work steps and materials. Even fiber composites can be precisely processed using lasers. The LZH is currently doing research on automated cutting of these lightweight materials, so that they can soon be used for mass production for automobile and aviation construction in the future.

Repair and Recycling: Extending the Lifetime of Lightweight Materials

Damage to wind power systems and aircraft wings can be selectively ablated and repaired using the laser, so that a whole rotor or wing need not be replaced. At the LZH stand, visitors can see how laser technology can be used to shorten the repair time and save material for leading-edge slats of a CFRP airplane wing. Visitors can also learn how CFRP cuttings can be recycled for use in new materials.

Visit the LZH at the joint stand of the state of Lower Saxony in hall 2, stand A 08!

Would you like to make an appointment with one of our experts?

Marketing & Communications

Dipl.-Biol. Lena Bennefeld

Phone: +49 511 2788-238

Fax: +49 511 2788-100

E-Mail: l.bennefeld@lzh.de

Laser Zentrum Hannover e.V. (LZH)

As an independent, non-profit research institute, the Laser Zentrum Hannover e.V. (LZH) stands for innovative research, development and consulting. The LZH is supported by the Lower Saxony Ministry for Economics, Labour and Transport and is dedicated to the selfless promotion of applied research in the field of photonics and laser technology. Founded in 1986, over 170 staff have achieved a turnover of 15.993 million euros (for 2013), among others, from income from federal, state, EU and industrial projects.

The focus of the LZH lies on the fields of optical components and systems, optical production technologies, and biomedical photonics. Interdisciplinary cooperation between natural scientists and mechanical engineers makes innovative approaches to challenges from the most different areas possible: from the development of components for specific laser systems to process developments for the most diverse laser applications, for example for medical technology or lightweight construction in the automotive sector. Seventeen spin off companies have emerged from the LZH up to now. Thus, the LZH has created a strong transfer between fundamental science, application oriented research, and industry.

Media Contact

All latest news from the category: HANNOVER MESSE

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…