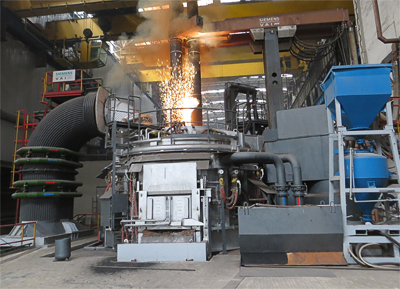

Electric arc furnace and off-gas cleaning from Siemens start operation at Baku Steel

The picture shows an Electric arc furnace from Siemens at Baku Steel in Azerbaijan. (Copyright: Baku Steel Company Ltd.)

Azerbaijani steel producer Baku Steel has put into operation an electric arc furnace supplied by Siemens Metals Technologies. The new furnace is part of an expansion project with which Baku Steel wishes to boost its annual production capacity to around 1.1 million metric tons of steel. The electric steel plant was equipped with an off-gas cleaning system as part of the project, so its dust emissions can be reduced to a maximum of 10 milligrams per standard cubic meter. Recently, Siemens also modernized the electric steel plant's ladle furnace and installed a dynamic compensation system.

Baku Steel Co. is the leading producer of structural steels in Azerbaijan. With the new 50-metric-ton electric arc furnace from Siemens, the company can produce 500,000 metric tons of steel a year, some 150,000 metric tons more than with the previous plant. This means that Baku Steel's production capacity will grow to an annual total of more than 1.1 million metric tons.

The off-gas cleaning system from Siemens comprises a primary dedusting system for the electric arc furnace and the 50-metric-ton ladle furnace as well as secondary dedusting system for the hall. The overall system has a capacity of around 950,000 Nm3/h. The fully automatic off-gas cleaning system limits the dust content in exhaust gases to a maximum of 10 milligrams per standard cubic meter, ensuring that dust emissions from Baku Steel's steel mill will meet European environmental standards.

The project also comprised mechanical equipment for the ladle furnace, including a compact portal, a water-cooled lid and current-conducting carrying arms as well as the basic automation of the arc furnace. A dynamic compensation system from Siemens was also installed, which – together with the modernized ladle furnace – commenced operation earlier this year. After completion of these measures, Baku Steel's electric arc furnace will achieve a specific energy consumption of 370 kilowatt hours with a current flow time of 35 minutes and electrode consumption amounting to 1.6 kilograms per metric ton of crude steel.

Further information about solutions for steel works, rolling mills and processing lines can be found at www.siemens.com/metals.

The Siemens Industry Sector (Erlangen, Germany) ist der weltweit führende Anbieter innovativer und umweltfreundlicher Produkte und Lösungen für Industrieunternehmen. Mit durchgängiger Automatisierungstechnik und Industriesoftware, fundierter Branchenexpertise und technologiebasiertem Service steigert der Sektor die Produktivität, Effizienz und die Flexibilität seiner Kunden. Der Sektor Industry hat weltweit mehr als 100.000 Beschäftigte und umfasst die Divisionen Industry Automation, Drive Technologies und Customer Services sowie die Business Unit Metals Technologies. Weitere Informationen finden Sie im Internet unter http://www.siemens.com/industry

The Metals Technologies Business Unit (Linz, Austria), im Siemens-Sektor Industry ist ein weltweit führender Lifecycle-Partner für die metallurgische Industrie. Die Business Unit bietet ein umfassendes Technologie-, Modernisierung-, Produkt- und Serviceportfolio und integrierte Automatisierungs- und Umweltlösungen für den gesamten Lebenszyklus von Anlagen. Weitere Informationen finden Sie im Internet unter http://www.siemens.com/metals

Reference Number: IMT201408554e

Contact

Mr. Rainer Schulze

Metals Technologies

Siemens AG

Turmstr. 44

4031 Linz

Austria

Tel: +49 (9131) 7-44544

All latest news from the category: Corporate News

Newest articles

Compact LCOS Microdisplay with Fast CMOS Backplane

…for High-Speed Light Modulation. Researchers from the Fraunhofer Institute for Photonic Microsystems IPMS, in collaboration with HOLOEYE Photonics AG, have developed a compact LCOS microdisplay with high refresh rates that…

New perspectives for material detection

CRC MARIE enters third funding period: A major success for terahertz research: Scientists at the University of Duisburg-Essen and the Ruhr University Bochum have been researching mobile material detection since…

CD Laboratory at TU Graz Researches New Semiconductor Materials

Using energy- and resource-saving methods, a research team at the Institute of Inorganic Chemistry at TU Graz aims to produce high-quality doped silicon layers for the electronics and solar industries….