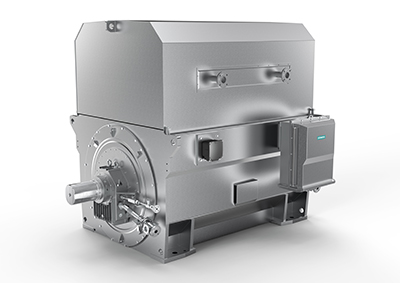

Modular concept up to 18 megawatts cuts project planning times for Simotics motors

The new motors from the Simotics HV M series cover an output range of 16 MW at 10 kV and 18 MW at 6 kV (50 Hz). The use of standard tools ensures shorter engineering times.

- New Simotics HV M motors in 4-pole and 6-pole variants with outputs of 16 MW at 10 kV and 18 MW at 6 kV (50 Hz)

- Available with Sinamics medium-voltage converters as an Integrated Drive System (IDS)

- Increased plant availability and short lead times

The Simotics HV M series with a shaft height of 800 millimeters is the latest addition to Siemens' portfolio of modular, high-voltage motors. In the 4-pole and 6-pole variants, outputs of up to 18 MW at 6 kV (50 Hz) are now achievable, extending the benefits of a modular motor concept to users in this performance class.

Standardized production and test processes cut lead times, increase plant availability and simplify spare parts storage. Integration into standard tools such as Sizer Web Engineering shortens project planning times, and the tool also supports users in configuring system components.

A wide range of options means that Simotics HV M motors can be adapted precisely to the individual applications; special paint systems, for example, protect against salty or other aggressive environments. In the Ex p or Ex n variant, the motors are suitable for use in areas subject to explosion hazards.

Variants are also available for use in extremely low temperatures down to -50°C or in applications with rigorous vibration quality requirements in line with the API standard.

The Simotics HV M motors can be equipped with a predictive condition monitoring system, and can be combined with Sinamics medium-voltage converters to form Integrated Drive Systems. On the design side, customers benefit in particular from the reduced weight of the steel enclosure, which makes it easier to transport the motors and integrate them into the plant. The increased torsional stiffness of the motors boosts reliability and makes for greater plant availability.

Simotics HV M motors are used above all in compressor applications such as gas pipelines, gas storage facilities, air separation units and rolling mills.

For further information on Simotics HV M motors, visit www.siemens.com/simotics

Siemens AG (Berlin and Munich) is a global technology powerhouse that has stood for engineering excellence, innovation, quality, reliability and internationality for more than 165 years. The company is active in more than 200 countries, focusing on the areas of electrification, automation and digitalization. One of the world's largest producers of energy-efficient, resource-saving technologies, Siemens is No. 1 in offshore wind turbine construction, a leading supplier of combined cycle turbines for power generation, a major provider of power transmission solutions and a pioneer in infrastructure solutions as well as automation, drive and software solutions for industry. The company is also a leading provider of medical imaging equipment – such as computed tomography and magnetic resonance imaging systems – and a leader in laboratory diagnostics as well as clinical IT. In fiscal 2014, which ended on September 30, 2014, Siemens generated revenue from continuing operations of €71.9 billion and net income of €5.5 billion. At the end of September 2014, the company had around 357,000 employees worldwide. Further information is available on the Internet at www.siemens.com

Reference Number: PR2015020106PDEN

Contact

Mr. Stefan Rauscher

Process Industries and Drives Division

Siemens AG

Gleiwitzer Str. 555

90475 Nuremberg

Germany

Tel: +49 (911) 895-7952

stefan.rauscher@siemens.com

Media Contact

All latest news from the category: Trade Fair News

Newest articles

NASA: Mystery of life’s handedness deepens

The mystery of why life uses molecules with specific orientations has deepened with a NASA-funded discovery that RNA — a key molecule thought to have potentially held the instructions for…

What are the effects of historic lithium mining on water quality?

Study reveals low levels of common contaminants but high levels of other elements in waters associated with an abandoned lithium mine. Lithium ore and mining waste from a historic lithium…

Quantum-inspired design boosts efficiency of heat-to-electricity conversion

Rice engineers take unconventional route to improving thermophotovoltaic systems. Researchers at Rice University have found a new way to improve a key element of thermophotovoltaic (TPV) systems, which convert heat…