Exploiting digitalization potential in the process industries with Siemens

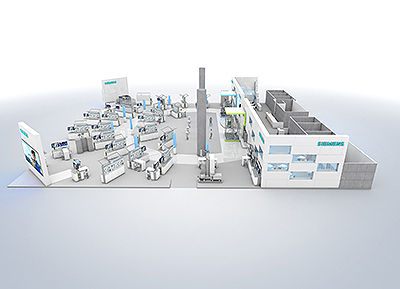

Based on the slogan "From Integrated Engineering to Integrated Operation – Discover the Potential of Digitalization" Siemens is focusing on the topic of digitalization at the Achema 2015 trade fair. With a booth area of some 1300 square meters, Siemens demonstrates how companies in the process industry can boost their efficiency and productivity – and thus also their competitiveness – by using integrated solutions.

Exhibiting at the Achema 2015, Siemens presented its strategy for digitalization in the process industries. “Companies operating within the process industries are under enormous competitive pressure, particularly as a result of changing regulations, markets and technologies. Digitalization is the central lever which will enable these challenges to be successfully met”, explained Peter Herweck, CEO of the Process Industries and Drives Division.

“On the way to the 'Digital Enterprise' we support our customers in this process by providing a unique integrated portfolio comprising hardware, software and services across the entire plant life cycle. The aim is to bring about a sustainable reduction in investment and operating costs”.

The underlying foundation for this are integrated software products and solutions which enable digitalization of the plant and consequently a seamless exchange of data – from the plant design and engineering stage through installation, operation and modernization to cloud-based services. This allows users to utilize a plant's virtual identical “digital twin” to simulate and optimize its commissioning, operation and maintenance.

“Whether we are talking about the construction of a new plant or the modernization of an existing one: investment in digitalization always pays off”, explained Peter Herweck. “This means that companies can increase their flexibility and shorten the time to market while adhering to regulations. Customers with long plan life cycles will benefit in particular from greater availability and reduced life cycle costs. In this way, digitalization opens up decisive competitive benefits to all companies across the process industries.”

Digitalization is enabled by integrated engineering. It reduces sources of error by lowering the number of interfaces required between different disciplines, increases quality throughout every step of the engineering workflow and shortens the time to market by enabling parallel work processes. In this way, tasks such as process engineering or electrotechnical planning are able to run alongside automation engineering.

The basis for this is provided by seamless interplay of the software solution Comos and the Simatic PCS 7 process control system. It enables integration not only horizontally across the entire plant life cycle but also vertically, from the office world (for instance ERP systems) down to the field level. One benefit is the scope this offers for integrating innovative process instrumentation such as high-precision Sitrans pressure transmitters. The integration process is further simplified by using established technology platforms such as Totally Integrated Automation (TIA), Totally Integrated Power (TIP) and Integrated Drive Systems (IDS).

Interlinking the planning and operating worlds

“By making the leap from integrated engineering to integrated operation, we are paving the way for our customers to take the next evolutionary step on the road to Industrie 4.0 by being the first supplier to develop an integrated data model,” explained Peter Herweck. “We are interlinking the world of planning with the world of operation to enable integrated system management over the entire life cycle of an industrial plant. This makes for more efficient work sequences, and enhances productivity and quality.

It entails consistent updating of plant data across the entire life cycle – as if you were creating a digital twin.” Data analyses performed during the operating phase allow users to obtain feedback regarding the status of important components such as pumps, motors and converters. This information can be used as the basis for developing an optimized maintenance strategy.

The result: improved plant availability and security. Software solutions such as the XHQ operations intelligence platform are also integrated, providing software to help users make more informed decisions. XHQ achieves this by aggregating, analyzing and presenting operational and business data, turning big data into smart data.

This service has a vital role to play in process plants, largely due to their long service life expectancy: Here, Siemens provides reliable support to companies with its comprehensive portfolio ranging from repair and remote services through to data and cloud-based services. With its “Control Performance Analytics” service, for instance, smart data analysis can optimize the performance of control loops, enhancing both production quality and output.

Siemens relies on industry-specific solutions to exploit the full potential of digitalization, such as paperless manufacturing (based on Simatic IT eBR) for the pharmaceutical industry. Paperless manufacturing speeds up the design, execution, review and release of pharmaceutical production processes and electronic batch records (EBRs). This allows companies to boost efficiency and product quality, as well as driving down costs while ensuring adherence to regulatory requirements.

Successful digitalization hinges on security and connectivity

For digitalization to succeed, it requires robust, reliable and primarily secure communication throughout every area of a plant. “There is no other supplier capable of supporting companies in the process industry with automation and drive technology as well as providing a comprehensive portfolio of industrial and fieldbus communication”, said Peter Herweck. The portfolio is additionally rounded off by products, solutions and services designed to enhance plant and process reliability.

For further information on Achema, please see www.siemens.com/press/achema2015

Siemens AG (Berlin and Munich) is a global technology powerhouse that has stood for engineering excellence, innovation, quality, reliability and internationality for more than 165 years. The company is active in more than 200 countries, focusing on the areas of electrification, automation and digitalization. One of the world's largest producers of energy-efficient, resource-saving technologies, Siemens is No. 1 in offshore wind turbine construction, a leading supplier of combined cycle turbines for power generation, a major provider of power transmission solutions and a pioneer in infrastructure solutions as well as automation, drive and software solutions for industry. The company is also a leading provider of medical imaging equipment – such as computed tomography and magnetic resonance imaging systems – and a leader in laboratory diagnostics as well as clinical IT. In fiscal 2014, which ended on September 30, 2014, Siemens generated revenue from continuing operations of €71.9 billion and net income of €5.5 billion. At the end of September 2014, the company had around 343,000 employees worldwide on a continuing basis.

Further information is available on the Internet at www.siemens.com

Reference Number: PR2015060248PDEN

Contact

Mr. David Petry

Process Industries and Drives Division

Siemens AG

Schuhstr. 60

91052 Erlangen

Germany

Tel: +49 (9131) 7-26616

david.petry@siemens.com

Media Contact

All latest news from the category: Trade Fair News

Newest articles

NASA: Mystery of life’s handedness deepens

The mystery of why life uses molecules with specific orientations has deepened with a NASA-funded discovery that RNA — a key molecule thought to have potentially held the instructions for…

What are the effects of historic lithium mining on water quality?

Study reveals low levels of common contaminants but high levels of other elements in waters associated with an abandoned lithium mine. Lithium ore and mining waste from a historic lithium…

Quantum-inspired design boosts efficiency of heat-to-electricity conversion

Rice engineers take unconventional route to improving thermophotovoltaic systems. Researchers at Rice University have found a new way to improve a key element of thermophotovoltaic (TPV) systems, which convert heat…