4-axis turning – double the output with two tools

- Sinumerik contour machining cycle expanded to include 4-axis turning

- Unique in the marketplace: simplest tool programming in two channels – even without a CAD/CAM system, directly on the control panel

- With two additional parameters for highly productive balanced cutting

- Two turning tools significantly reduce machining time and improve dimensional accuracy

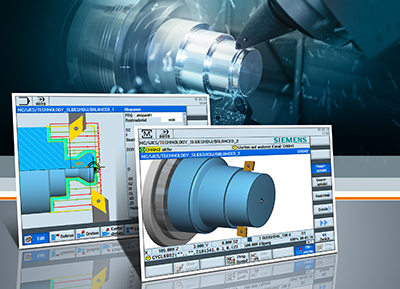

The expanded contour machining cycle for Siemens Sinumerik CNC controllers now facilitates 4-axis turning on lathes. Two turning tools opposite one another machine the workpiece simultaneously, enabling the machining time to be significantly reduced. In addition, the two turning tools opposite one another prevent workpiece distortion, significantly improving dimensional accuracy, particularly on long, thin workpieces. A unique advantage of the Siemens controls is that the new machining process can be programmed directly on the Sinumerik CNC without a CAD/CAM system. With just two additional parameters, the user expands the machining process for a tool into highly productive balanced cutting with two tools, the Sinumerik contour machining cycle automatically creating the CNC sequences.

In 4-axis machining a distinction is made between synchronous and asynchronous path control, with the channel based Sinumerik, executing two independent CNC programs simultaneously.

In synchronous machining, which is particularly suited for roughing and finishing, the cutting inserts are exactly opposite one another and move identically. The cutting depth, equally distributed over both cutting edges, making it possible to double the feed rate per revolution and chip volume.

In asynchronous path control used for roughing, the two tools move differently. In longitudinal turning the cutting inserts work at different diameters and in face turning they work at different Z positions. By short waiting times for tool synchronization, the chip volume relative to a tool can be roughly doubled.

For further information on Sinumerik CNC4you, please see www.siemens.com/cnc4you

For further information on Siemens at EMO 2015, please see

www.siemens.com/emo

Siemens AG (Berlin and Munich) is a global technology powerhouse that has stood for engineering excellence, innovation, quality, reliability and internationality for more than 165 years. The company is active in more than 200 countries, focusing on the areas of electrification, automation and digitalization. One of the world's largest producers of energy-efficient, resource-saving technologies, Siemens is No. 1 in offshore wind turbine construction, a leading supplier of combined cycle turbines for power generation, a major provider of power transmission solutions and a pioneer in infrastructure solutions as well as automation, drive and software solutions for industry. The company is also a leading provider of medical imaging equipment – such as computed tomography and magnetic resonance imaging systems – and a leader in laboratory diagnostics as well as clinical IT. In fiscal 2014, which ended on September 30, 2014, Siemens generated revenue from continuing operations of €71.9 billion and net income of €5.5 billion. At the end of September 2014, the company had around 343,000 employees worldwide on a continuing basis.

Further information is available on the Internet at www.siemens.com

Reference Number: PR2015070270DFEN

Contact

Mr. Peter Jefimiec

Digital Factory Division

Siemens AG

Gleiwitzer Str. 555

90475 Nuremberg

Germany

Tel: +49 (911) 895-7975

peter.jefimiec@siemens.com

Media Contact

All latest news from the category: Trade Fair News

Newest articles

Innovative vortex beam technology

…unleashes ultra-secure, high-capacity data transmission. Scientists have developed a breakthrough optical technology that could dramatically enhance the capacity and security of data transmission (Fig. 1). By utilizing a new type…

Tiny dancers: Scientists synchronise bacterial motion

Researchers at TU Delft have discovered that E. coli bacteria can synchronise their movements, creating order in seemingly random biological systems. By trapping individual bacteria in micro-engineered circular cavities and…

Primary investigation on ram-rotor detonation engine

Detonation is a supersonic combustion wave, characterized by a shock wave driven by the energy release from closely coupled chemical reactions. It is a typical form of pressure gain combustion,…