New hybrid inks permit printed, flexible electronics without sintering

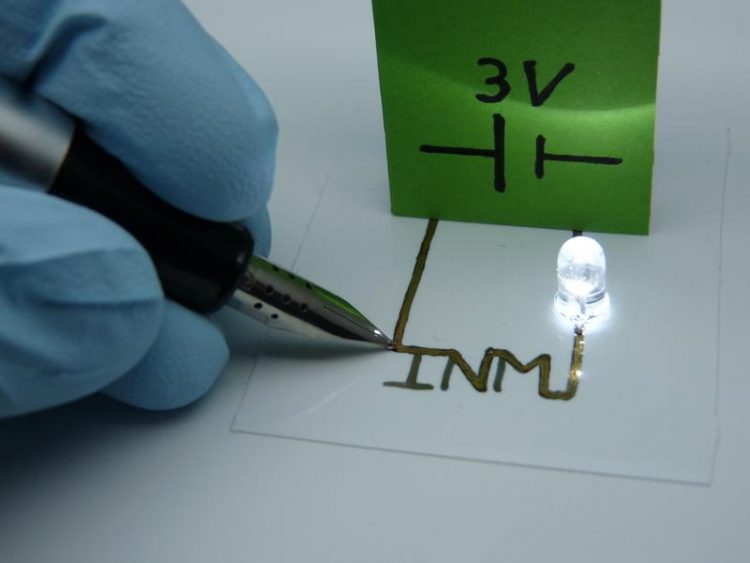

New hybrid inks permit printed, flexible electronics without sintering. Copyright: INM

The electronics of the future will be printed. Flexible circuits can be produced inexpensively on foil or paper using printing processes and permit futuristic designs with curved diodes or input elements. This requires printable electronic materials that can be printed and retain a high level of conductivity during usage in spite of their curved surfaces.

Some tried and tested materials include organic, conductive polymers and nanoparticles made of conductive oxides (TCOs). Research scientists at INM – Leibniz-Institute for New Materials have now combined the benefits of organic and inorganic electronic materials in a new type of hybrid inks. This allows electronic circuits to be applied to paper directly from a pen, for example.

The developers will be demonstrating their results and the possibilities they offer at stand B46 in hall 2 at this year's Hanover Trade Fair as part of the leading trade show Research & Technology which takes place from 25th to 29th April.

To create their hybrid inks, the research scientists coated nanoparticles made of metals with organic, conductive polymers and suspended them in mixtures of water and alcohol. These suspensions can be applied directly on paper or foil using a pen and they dry without any further processing to form electrical circuits.

“Electrically conductive polymers are used in OLEDs, for example, which can also be manufactured on flexible substrates,” explains Tobias Kraus, Head of the research group Structure Formation at INM. “The combination of metal and nano-particles that we introduce here combines mechanical flexibility with the robustness of a metal and increases the electrical conductivity”.

The developers combine the organic polymers with gold or silver nanoparticles. The organic compounds have three functions: “On the one hand, the compounds serve as ligands, ensuring that the nanoparticles remain suspended in the liquid mixture; any agglomeration of particles would have a negative effect on the printing process. Simultaneously, the organic ligands ensure that the nanoparticles have a good arrangement when drying.

Ultimately, the organic compounds act as ´hinges´: if the material is bent, they maintain the electrical conductivity. In a layer of metal particles without the polymer sheath the electrical conductivity would quickly be lost when the material is bent,” the material scientist Kraus continues. Due to the combination of both materials, when bent, the electrical conductivity is greater all in all than in a layer that is made purely of conductive polymer or a layer made purely of metal nanoparticles.

“Metal nanoparticles with ligands are already printed to form electronics today,” explains the physical chemist Kraus, adding that the shells mostly had to be removed by a sintering process because, while on the one hand they control the arrangement of the nanoparticles, on the other hand, they are not conductive.

He added that this was difficult in the case of carrier materials that are sensitive to temperature such as paper or polymer films since these would be damaged during the sintering process. Kraus summarizes the results of his research, saying, “Our new hybrid inks are conductive as soon as they have dried as well as being particularly mechanically flexible and they do not require sintering”.

Original publication:

B. Reiser, L. González-García, I. Kanelidis, J. H. M. Maurera, T. Kraus; Gold nanorods with conjugated polymer ligands: sintering-free conductive inks for printed electronics; Chem. Sci., 2016; DOI: 10.1039/C6SC00142D

Your expert at INM:

Dr. Tobias Kraus

INM – Leibniz-Institut für Neue Materialien

Leiter Strukturbildung

Stellv. Leiter InnovationsZentrum INM

Tel: +49 681-9300-389

tobias.kraus@leibniz-inm.de

INM conducts research and development to create new materials – for today, tomorrow and beyond. Chemists, physicists, biologists, materials scientists and engineers team up to focus on these essential questions: Which material properties are new, how can they be investigated and how can they be tailored for industrial applications in the future? Four research thrusts determine the current developments at INM: New materials for energy application, new concepts for medical surfaces, new surface materials for tribological systems and nano safety and nano bio. Research at INM is performed in three fields: Nanocomposite Technology, Interface Materials, and Bio Interfaces.

INM – Leibniz Institute for New Materials, situated in Saarbrücken, is an internationally leading centre for materials research. It is an institute of the Leibniz Association and has about 220 employees.

http://www.leibniz-inm.de/en

http://www.leibniz-gemeinschaft.de/en

Media Contact

All latest news from the category: Trade Fair News

Newest articles

NASA: Mystery of life’s handedness deepens

The mystery of why life uses molecules with specific orientations has deepened with a NASA-funded discovery that RNA — a key molecule thought to have potentially held the instructions for…

What are the effects of historic lithium mining on water quality?

Study reveals low levels of common contaminants but high levels of other elements in waters associated with an abandoned lithium mine. Lithium ore and mining waste from a historic lithium…

Quantum-inspired design boosts efficiency of heat-to-electricity conversion

Rice engineers take unconventional route to improving thermophotovoltaic systems. Researchers at Rice University have found a new way to improve a key element of thermophotovoltaic (TPV) systems, which convert heat…