DBFZ work out IEA study on wood pellet market in more than thirty countries

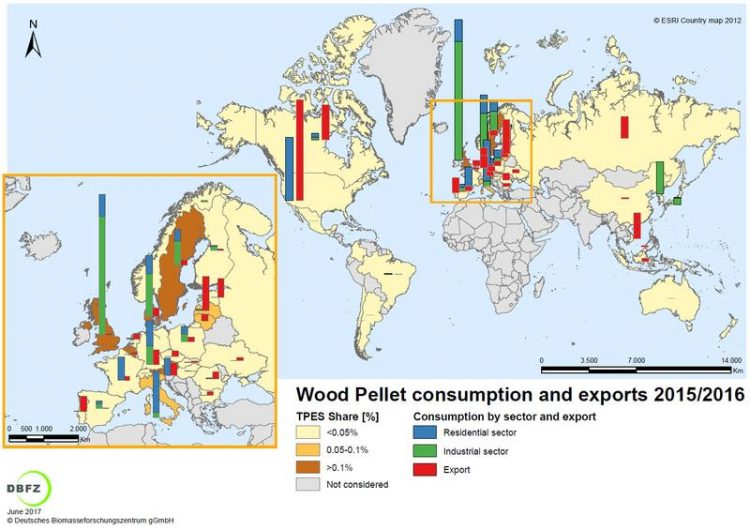

Countries with relevant wood pellet consumption and/or export in 2015/2016 DBFZ, 2017

Driven by rising demand, the global production of wood pellets has risen rapidly over the last ten years. While the production volume in 2006 was estimated at 6-7 megatons (Mt), it already exceeded 26 Mt in 2015/2016. Further growth in demand is expected in the coming years for applications in two market segments.

On the one hand, certified wood pellets are burned in coal-fired power stations and in converted coal-fired power plants to reduce greenhouse gas emissions during the generation of electricity. On the domestic side, wood pellets are used as a solid fuel mainly in automated furnaces and boilers. In the future, according to the assessment of the authors, wood pellets could also represent a renewable resource for “green chemistry” and biobased materials.

European Union as region is the largest pellet producer in the world

Due to an increasing demand, especially in Europe, the EU as region was by far the largest producer of wood pellets (54% by 2015), followed by North America (2015: 35%). Canada recorded the world's most dynamic development and was able to increase exports from 1.6 Mt in 2015 to 2.4 Mt in 2016. Seen on a country-by-country basis, the United States clearly dominates pellet production with 7.4 Mt in 2015 and 6.3 Mt in 2016, but is faced with a growing competition from Europe, Russia and the Baltic States.

Other major producers are Germany with 2.2 Mt and Sweden with 1.5 Mt. Asia, the Russian Federation, Australia and Latin America play even smaller roles in global pellet production (2015: 11%), but are growing. In terms of national pellet consumption, the United Kingdom was at 6.7 mt, followed by the United States (2.8 mt) and Italy (2.1 mt).

However, the rapid development of the global wood pellet market also leads to new challenges, according to the study. In many producing countries, an appropriate and sustainable infrastructure has to be developed and built up with regard to biomass supply, pellet storage, loading, handling of capacities in the production regions as well as in commercial areas and ports, for example.

Numerous regulatory measures have already been implemented by policy makers, pellet consumers as well as technology developers, but developments from country to country vary considerably. In addition to the already achieved standards, the development of sustainability criteria for wood, successful certifications and technologies for the provision of pellets from more sophisticated raw materials (for example, the fermentation of raw materials on a straw basis), the study shows, that there is still a great deal of potential for optimization of the achievable Greenhouse gas savings by wood pellets.

A sustainable climate protection plan in the countries is a key factor

“A key factor in the development of a global industrial market for wood pellets is the introduction of (political) framework, the creation of markets and standards and the implementation of a sustainable climate protection plan in the countries. This is already ambitiously implemented in Europe, but we see that, for example, the countries in Southeast Asia are on the way to put this issue on the agenda. With the study, we have analysed key indicators on the pellet market from more than 30 countries, which makes the work of the last twelve months extremely valuable for all relevant stakeholders”, said the author of the study, Prof. Dr.-Ing. Daniela Thrän from DBFZ and Helmholtz Centre for Environmental Research.

Download

The entire report (243 pages) is available free of charge in English under the following link as a PDF download: www.ieabioenergy.com

Smart Bioenergy – innovations for a sustainable future

DBFZ, the German Centre for Biomass Research, works as a central and independent thinker in the field of energy and material use of biomass on the question of how the limited available biomass resources can contribute to the existing and future energy system with sustainability and high efficiency. As part of the research the DBFZ identifies, develops, accompanies, evaluates and demonstrates the most promising fields of application for bioenergy and the especially positively outstanding examples together with partners from research, industry and public. With the scientific work of the DBFZ, the knowledge of the possibilities and limitations of energy and integrated material use of renewable raw materials in a biobased economy as a whole should be expanded and the outstanding position of the industrial location Germany in this sector permanently secured – www.dbfz.de

Scientific Contact:

Prof. Dr.-Ing. Daniela Thrän

Phone: +49 (0)341 2434-435

E-Mail: daniela.thraen(at)dbfz(dot)de

Press Contact:

Paul Trainer

Phone: +49 (0)341 2434-437

E-Mail: paul.trainer(at)dbfz(dot)de

https://www.dbfz.de/index.php?id=1216&L=1

http://www.ieabioenergy.com/publications/global-wood-pellet-industry-and-trade-s…

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

NASA: Mystery of life’s handedness deepens

The mystery of why life uses molecules with specific orientations has deepened with a NASA-funded discovery that RNA — a key molecule thought to have potentially held the instructions for…

What are the effects of historic lithium mining on water quality?

Study reveals low levels of common contaminants but high levels of other elements in waters associated with an abandoned lithium mine. Lithium ore and mining waste from a historic lithium…

Quantum-inspired design boosts efficiency of heat-to-electricity conversion

Rice engineers take unconventional route to improving thermophotovoltaic systems. Researchers at Rice University have found a new way to improve a key element of thermophotovoltaic (TPV) systems, which convert heat…