Beyond the clouds: Networked clouds in a production setting

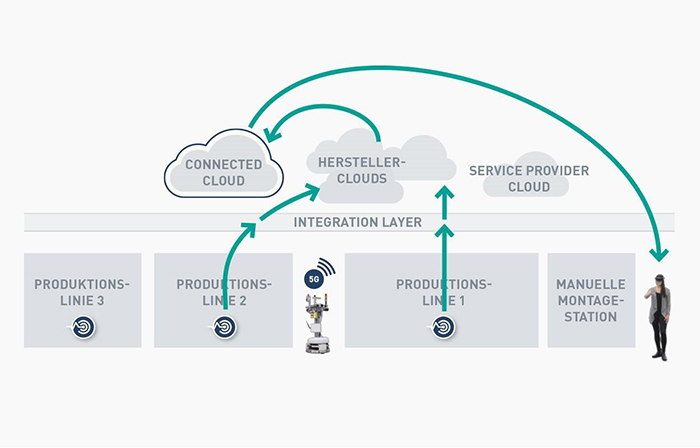

Different clouds used at the SmartFactoryKL Industrie 4.0 production plant. SmartFactoryKL/A. Sell

How can data be evaluated and interpreted in its entirety in a cloud when the production plant uses different cloud solutions? The partner consortium behind SmartFactoryKL provides the answer: a higher level cloud platform that aggregates all cloud solutions.

This solution is presented at the joint exhibit stand of SmartFactoryKL and the German Research Center for Artificial Intelligence (DFKI) at the Hannover Messe from April 23-27, 2018 (Hall 8, Stand D18).

Manufacturing companies use data-driven applications to make reliable predictions about the status of the production plant. Various cloud solutions necessary for data analysis and interpretation are available on the market. Each of these solutions provides the expert knowledge required for reliable data interpretation for the specific application.

These individual clouds initially present manufacturer-specific solutions. The various production data can only be merged to provide an overall picture of the plant in a manufacturer-independent manner when networked through a higher level cloud platform.

Use Case SmartFactoryKL Cloud

SmartFactoryKL demonstrates just such a cloud platform – one that aggregates the entire expert knowledge of all cloud solutions – in collaboration with its partners at the production plant. At the SmartFactoryKL facility, various cloud solutions are connected to the assembly modules by the corresponding edge devices. For example, for predictive maintenance the quality assurance module uses a different cloud than the assembly module.

The SmartFactoryKL cloud, as the higher level cloud platform, merges the data from the separate manufacturer clouds and checks it before making the targeted distribution. In this way, the SmartFactoryKL cloud draws conclusions from faulty or deviant data and communicates the appropriate maintenance instruction via smart phone or a smart device like data glasses to the worker.

The user-specific services of the future will still be provided only by experts, i.e., the suppliers of individual cloud solutions. This means that a company is required to access multiple clouds containing different data. For practical purposes, this implies a manufacturing cloud platform that can be networked with the various clouds in use.

Additional Use Case: Service-provider cloud via 5G technology

The Service Provider Cloud is directly linked via 5G technology to the flexible transport system and carries out the actual quality control using the optical recognition data for the workpiece (see press release “5G” dated: March 6, 2018).

“We see an emerging trend that clouds, like machines, can be viewed as services that can be modularly combined. Consider the pay-per-use payment system, where the user pays only for the services that have been called up from multiple providers. Another advantage in exploiting cloud platforms is the relative ease of operation. For example, even automation developers who are not IT experts use this concept,” said Prof. Dr. Detlef Zühlke, CEO of SmartFactoryKL.

The partners involved in the Industrie 4.0 demonstrator at SmartFactoryKL are: Belden/Hirschmann, Bosch Rexroth, B&R Automation, EPLAN Software & Service, Festo, HARTING, Huawei, IBM, KIST Europe, LAPP KABEL, METTLER TOLEDO, MiniTec, PHOENIX CONTACT, Pilz, proALPHA, SAP, Siemens, TÜV SÜD, and Weidmüller.

About the Technologie-Initiative SmartFactory KL e.V.:

The SmartFactoryKL technology initiative was established as a non-profit organization in 2005, bringing together for the first time industrial and research partners in an Industrie 4.0 network to implement joint projects for the factories of the future. SmartFactoryKL is a unique, manufacturer-independent demonstrator and research vehicle located at the German Research Center for Artificial Intelligence (DFKI) in Kaiserslautern.

Promising innovative Information and Communication Technologies (ICT) are evaluated and further developed in a realistic industrial production environment on site. Products and solutions as well as universal standards in the areas of Industrie 4.0 have already been developed at the technology initiative with the active participation of its members.

Together with other regional competence suppliers, SmartFactoryKL was recognized by the German Federal Ministry for Economic Affairs and Energy (BMWi) and designated as SME 4.0 Competence Centrum Kaiserslautern.

About the German Research Center for Artificial Intelligence (DFKI):

The German Research Center for Artificial Intelligence, with sites in Kaiserslautern, Saarbrücken, Bremen (with an associated branch in Osnabrück) and a project office in Berlin, is the leading German research institute in the field of innovative software technology. In the international scientific community, DFKI ranks among the most recognized “Centers of Excellence” and currently is the biggest research center worldwide in the area of Artificial Intelligence and its application in terms of number of employees and the volume of external funds. The financial budget in 2016 was 44.1 million Euro.

DFKI projects cover the whole spectrum from application-oriented basic research to market- and client-oriented design of product functions. 519 employees from 60 countries are currently conducting research focusing on Smart Data & Knowledge Services, Cyber-Physical Systems, Multilingual Technologies, Plan-Based Robot Control, Educational Technology Lab, Interactive Textiles, Robotics, Innovative Retail, Information Systems, Embedded Intelligence, Smart Service Engineering, Intelligent Analytics for Massive Data, Intelligent Networks, Agents and Simulated Reality, Augmented Vision, Language Technology, Intelligent User interfaces, and Innovative Factory Systems. Impact: more than 100 professorships of former DFKI employees, and more than 70 spin-off companies with approximately 2,500 highly qualified jobs.

Press Contact:

Dr. Haike Frank

Head of Public Relations Department

Technologie-Initiative SmartFactory KL e.V.

Trippstadter Straße 122

67663 Kaiserslautern

T: 0631/20575-3406

M: frank@smartfactory.de

Christian Heyer

Head of DFKI Communications Department Kaiserslautern

Deutsches Forschungszentrum für Künstliche Intelligenz (DFKI) GmbH

Trippstadter Straße 122

67663 Kaiserslautern

T: +49 631 20575 1710

M: uk-kl@dfki.de

https://cloud.dfki.de/owncloud/index.php/s/ygk3pbXTYISww8i Photo download link

https://www.dfki.de/en DFKI homepage

http://www.smartfactory.de/en SmartFactoryKL homepage

Media Contact

All latest news from the category: Information Technology

Here you can find a summary of innovations in the fields of information and data processing and up-to-date developments on IT equipment and hardware.

This area covers topics such as IT services, IT architectures, IT management and telecommunications.

Newest articles

NASA: Mystery of life’s handedness deepens

The mystery of why life uses molecules with specific orientations has deepened with a NASA-funded discovery that RNA — a key molecule thought to have potentially held the instructions for…

What are the effects of historic lithium mining on water quality?

Study reveals low levels of common contaminants but high levels of other elements in waters associated with an abandoned lithium mine. Lithium ore and mining waste from a historic lithium…

Quantum-inspired design boosts efficiency of heat-to-electricity conversion

Rice engineers take unconventional route to improving thermophotovoltaic systems. Researchers at Rice University have found a new way to improve a key element of thermophotovoltaic (TPV) systems, which convert heat…