First implementation of Gecomer®-Technology in a Collaborative Robot

First implementation of Gecomer<sup>®</sup> Technology in a Collaborative Robot Source: INM, Henrik Ollmann; free within this content

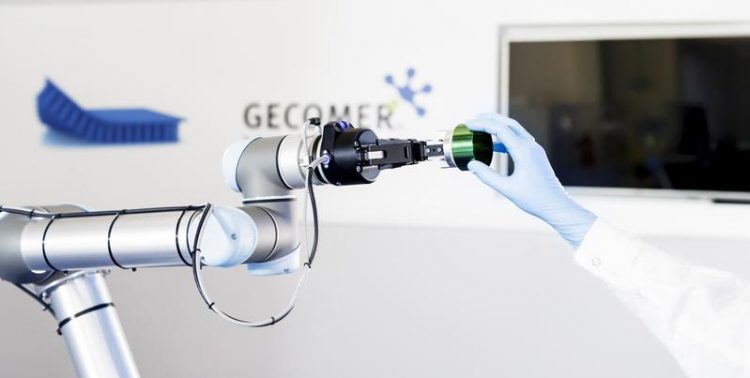

Collaborative robots are a new generation of robots for direct cooperation with humans, even without a safety distance or protective cages. Scientists at the INM – Leibniz Institute for New Materials now present a Cobot for the first time which is equipped with microstructured surfaces for the handling of objects. Because these structures are very soft and have no sharp corners or edges, the risk of injury to humans is further reduced.

The soft Cobot can be seen at this year's Hannover Messe in Hall 5, Industrial Supply, in the Surface Technology Area at Stand C54.

“Our innovative adhesive systems are made of a highly elastic material. The gripping and detaching of objects is affected by smart surface structures. This enables us to dispense with pointed grippers or tweezers,” says Eduard Arzt, Scientific Director and Head of the Functional Microstructures Program Division.

As a result, objects can be transported and deposited in the production process without any risk of injury to humans or damage to the objects. The adhesive structures are particularly suitable for sensitive parts, such as devices for the automotive, semiconductor and display industries.

“Our innovation can be expanded to include all processes in which Cobots are used, even in challenging environments such as vacuum. We are confident that our Gecomer® structures will also conquer this market”, adds Karsten Moh, Head of Gecomer® Applications at INM.

Regardless of whether the structures are used in robots or in Cobots, researchers at INM have not only proven the suitability of Gecomer® in various industrial environments. In their InnovationCenter, they also successfully developed an advanced roll-to-roll process, which enables the adhesive structures to be produced in large quantities at low cost.

Background

With its planned spin-off company INNOCISE, INM is taking the developments of Gecomer® adhesive structures to the market. INNOCISE was nominated for the Leibniz Start-Up Award, the “Leibniz-Gründerpreis 2019”.

Your expert at INM:

Prof. Dr. Eduard Arzt

Head Functional Microstructures

Phone: +49681-9300-500

eduard.arzt@leibniz-inm.de

Dan Yu, Dirk Beckelmann, Michael Opsölder, Bruno Schäfer, Karsten Moh, René Hensel, Peter William De Oliveira and Eduard Arzt „Roll-to-Roll Manufacturing of Micropatterned Adhesives by Template Compression”; Materials 2019, 12(1), 97; https://doi.org/10.3390/ma12010097

Media Contact

All latest news from the category: Trade Fair News

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…