Laser Goes Green: Efficiently Recycling Valuable Materials from Electronic Devices

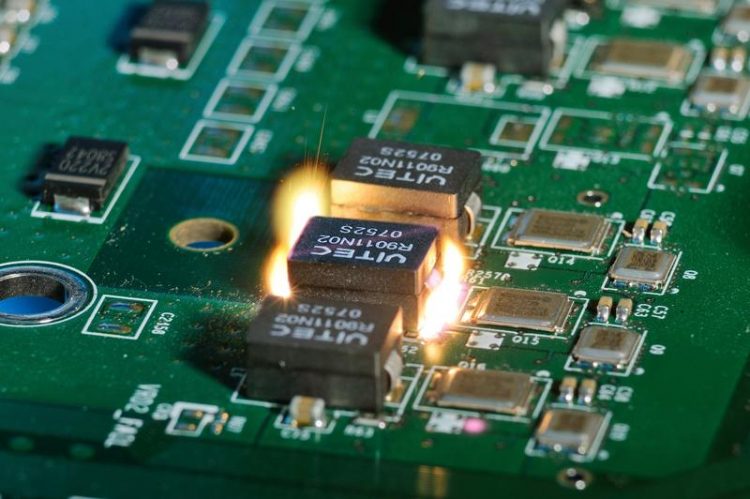

In the recycling process of the "ADIR" project, the laser takes over the non-contact desoldering of electronic components mounted on printed circuit boards. ©Fraunhofer ILT, Aachen, Germany

A magic word is making the rounds: “Urban Mining”. This new form of mining recovers secondary raw materials from buildings, infrastructure or products. If put into practice for electronic devices, this ecological idea could be particularly rewarding; however, it is still necessary to develop methods that allow, for example, mobile phones and printed circuit boards to be reliably, automatically and efficiently disassembled into their components in order to recover valuable raw materials for reuse in new electronics.

Two-part symposium: Recycling of valuable materials in theory and practice

“In the last two years, systems have been developed that have put our project ideas into practice”, explains Prof. Reinhard Noll, coordinator of “ADIR” from Fraunhofer ILT. “On May 17, a two-part event will take place in Goslar for a national and international scientific-technical audience.”

In the morning, the ADIR consortium partners will report about the results of the EU project and in the afternoon the developed machines and processes will be presented at the facilities of the local Electrocycling GmbH (ECG).

ECG, a certified specialist for environmentally friendly WEEE recycling, is testing the ADIR methods in field tests since 2018 in order to validate them for industrial use. Dr. Cord Fricke-Begemann, scientist at Fraunhofer ILT and “ADIR” project manager, explains, “We will exhibit, with the help of the demonstrator, how laser-based material recycling works in practice on mobile phones and computer boards. ECG shows that the technologies developed in the ADIR project also allow large quantities of valuable materials, such as tantalum, to be recovered from capacitors”.

Inverse Production: At the center is the use of lasers

The ADIR team is guided by the concept of so-called inverse production, which, in contrast to conventional shredding and pyrometallurgy processes, in the first instance measures and analyzes the end-of-life electronics and then selectively disassembles valuable components to gain novel, highly enriched sorting fractions. The residual material is fed to proven metallurgical processes.

The project partners are relying on automated, flexible processes with which electronic devices at their end of use can be automatically disassembled into their individual parts. In the disassembly plant, there is a clever interaction of laser technology, robotics, vision systems and information technology.

An important role in this concept is played by laser processes, which, among other things, not only identify ingredients in electronic components in real time, but also desolder or cut-out electronic components without contacting them. The fact that the process can efficiently recycle strategic materials of high economic importance on an industrial scale speaks for itself. Fricke-Begemann: “With ADIR, we are reducing the EU's dependency on natural resources and costly material imports”.

Get more information and watch the video: www.adir.eu

Dr. rer. nat. Cord Fricke-Begemann

Group manager for Materials Analysis

Telephone +49 241 8906-196

cord.fricke-begemann@ilt.fraunhofer.de

Prof. Dr. rer. nat. Reinhard Noll

Competence area manager Measurement Technology and EUV Beam Sources

Telephone +49 241 8906 138

reinhard.noll@ilt.fraunhofer.de

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

A ‘language’ for ML models to predict nanopore properties

A large number of 2D materials like graphene can have nanopores – small holes formed by missing atoms through which foreign substances can pass. The properties of these nanopores dictate many…

Clinically validated, wearable ultrasound patch

… for continuous blood pressure monitoring. A team of researchers at the University of California San Diego has developed a new and improved wearable ultrasound patch for continuous and noninvasive…

A new puzzle piece for string theory research

Dr. Ksenia Fedosova from the Cluster of Excellence Mathematics Münster, along with an international research team, has proven a conjecture in string theory that physicists had proposed regarding certain equations….