Technological Ray of Hope for the Snowboard Scene

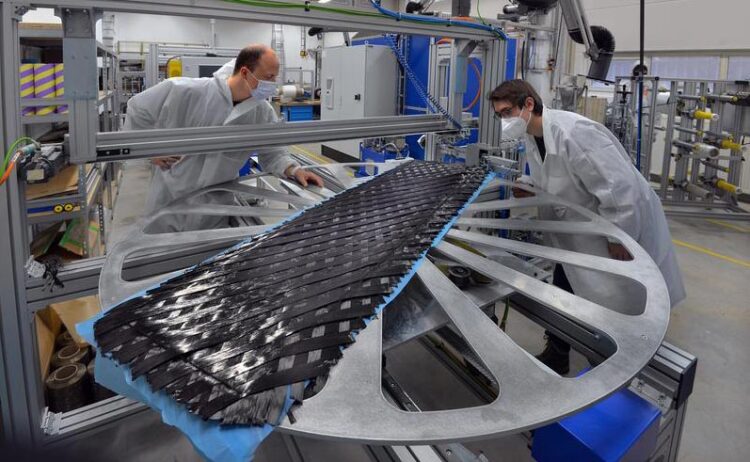

Jakob Schmidt (l) and Marc Fleischmann, research assistants at the Department of Textile Technologies at Chemnitz University of Technology, check the quality of a splitboard’s preform on the turntable of a special system.

TU Chemnitz

New snowboard from Chemnitz is lighter than comparable boards and can be manufactured far more ecologically – the Department of Textile Technologies uses the dry fiber placement process.

The snowboard – every winter sports enthusiast knows it. The first boards for gliding over snow existed as early as 1900, but it was not until 1963 that American surfers brought the feeling of surfing to the snow and developed the original snowboard – the so-called snurfer.

A few years later, the snowboard drew the interest of the winter sports industry, and since 1998 snowboarding has been recognized as an Olympic sport. It is no wonder that this discipline has increasingly attracted the attention of the scientific community in recent years – including Chemnitz University of Technology.

Their latest innovation comes from the 2020/2021 winter sports season: researchers from the Department of Textile Technologies, together with silbaerg GmbH – a spin-off from the Institute of Lightweight Structures at Chemnitz University of Technology – have developed a very lightweight snowboard that can also be manufactured far more sustainably than comparable boards.

This is made possible by a new type of textile fiber semi-finished product made of carbon fibers. By using the dry fiber placement process, fiber waste in snowboard production can be reduced by around 60 percent. “This not only saves costs, but thanks to the board’s sustainable production, its carbon footprint is also significantly reduced,” says Prof. Dr. Holger Cebulla, head of the Chair of Textile Technologies.

Successful trial by fire for the splitboard variant

The first prototype of the new board from Chemnitz was manufactured as a splitboard. This is a snowboard that – as the name suggests – can be split into two touring skis. One tours comfortably up the mountain on two skis to the downhill point, where the touring skis are reassembled into a snowboard in a few simple steps. The Chemnitz-developed board has an advantage. “With a weight of 2.6 kilograms and a length of 1.59 meters, the splitboard is one of the lightest in the industry,” states Dr. Jörg Kaufmann, manager of the composites division at the Department of Textile Technologies.

Thanks to the dry fiber placement process used at the Department of Textile Technologies, it was possible to use the unique A.L.D. technology developed ten years ago at Chemnitz University of Technology’s Institute of Lightweight Structures for the splitboard. A.L.D. stands for Anisotropic Layer Design and refers to the special glass and carbon fibers around the wood core of a snowboard.

“This allows the edges to deform depending on the riding situation, which noticeably improves the ride,” Kaufmann says. For example, edge hold increases when the edge presses into the snow during a turn. “On the other hand, during boardslide, a trick in which the snowboarder jumps onto an obstacle with a 90-degree turn and slides over it, the edge manages to lift off the rail,” Kaufmann adds. This prevents boards from wearing down and makes it more difficult for them to warp, he adds.

The splitboard’s first tests in the Erzgebirge and the Alps also convinced the professionals. “Due to the weight savings, touring on a mountain is much easier and peaks can be climbed that were previously unreachable,” reports Paul Baudach, graduate of the university’s sports engineering program and university champion in boardercross and slopestyle snowboarding. “I was surprised by how well the board handled both off-piste and on-piste,” says the top athlete. For him, it is clear that the new board can also be used to win at boardercross.

“Of course, we hope that in addition to the splitboard, the dry fiber placement process in board manufacture and the use of textile fiber semi-finished products made of carbon fibers will continue to gain acceptance in the sports equipment industry and that their advantages will be received by customers,” said Cebulla.

Wissenschaftliche Ansprechpartner:

Prof. Dr. Holger Cebulla, Phone +49 371 531-35318, E-mail holger.cebulla@mb.tu-chemnitz.de, and Dr. Jörg Kaufmann, Phone +49 371 531-36473, E-mail joerg.kaufmann@mb.tu-chemnitz.de

Media Contact

All latest news from the category: Innovative Products

Newest articles

Compact LCOS Microdisplay with Fast CMOS Backplane

…for High-Speed Light Modulation. Researchers from the Fraunhofer Institute for Photonic Microsystems IPMS, in collaboration with HOLOEYE Photonics AG, have developed a compact LCOS microdisplay with high refresh rates that…

New perspectives for material detection

CRC MARIE enters third funding period: A major success for terahertz research: Scientists at the University of Duisburg-Essen and the Ruhr University Bochum have been researching mobile material detection since…

CD Laboratory at TU Graz Researches New Semiconductor Materials

Using energy- and resource-saving methods, a research team at the Institute of Inorganic Chemistry at TU Graz aims to produce high-quality doped silicon layers for the electronics and solar industries….