The Hidden Chemical Life of Defects

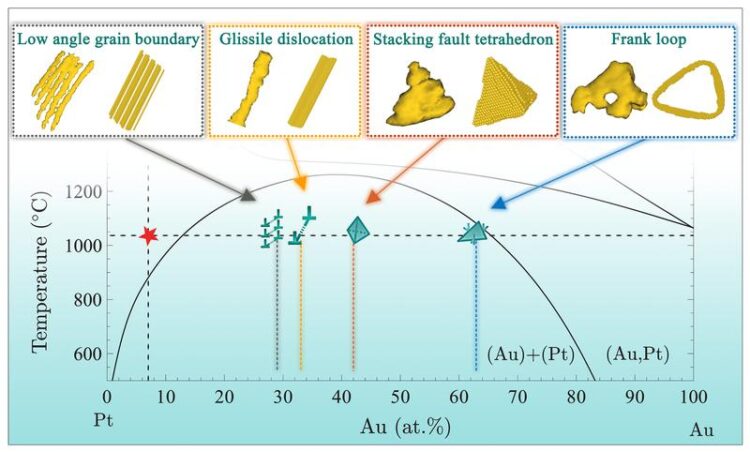

How Au atoms arrange around different defects in Pt-Au alloy, investigated in experiments and simulations. Below: room pressure equilibrium Pt-Au phase diagram

© X. Zhou, J.R. Mianroodi, et al: Science Advances 2021

Max Planck scientists publish latest results in the journal Science Advances …

Metals are one of the most important materials in our civilization due to their excellent strength and formability. The possibility to permanently deform and shape metals without breaking, makes them the material of choice for many high-tech products. Their plastic deformation is typically carried by motion of defects called dislocations, in the lattice structure.

As the dislocations move, they deform the material permanently, allowing the metal to assume new form. Therefore, the motion of dislocations is the key in understanding the plastic deformation of metals. However, their motion is still not well understood. What influences the motion of defects through a material? And how does their chemical composition interact with the material’s properties?

Most of the engineering metallic materials combine different elements. Although dislocations have been studied for many years, the effect of chemical composition on their properties is not well understood. Researchers from the Max-Planck-Institut für Eisenforschung (MPIE) and their partners at the RWTH Aachen University (Germany), the University of Alabama (USA), the University of Manchester (UK) and the Imperial College London (UK) have now shown that the atomic nature of these defects is determined not only by structural features, but also by their chemical composition. Each defect type moves differently in the lattice structure thus influencing the material’s properties differently. The international researcher team published their latest findings in the journal Science Advances.

Recent advances in atomic scale material characterization have enabled the nanoscopic quantitative investigation of defect types and their interaction with chemistry. According to the latest findings of the Max Planck team, it is necessary to revise the conventional picture of how atoms of different elements in an alloy segregate to dislocations. For over 70 years now, theory suggested that solute atoms gather quasi-randomly around dislocations as clouds. This phenomenon is known as the Cottrell-cloud, named after Alan Cottrell, being one of the scientists who described this theory.

“We used a binary platinum-gold model alloy and revealed the realm of complex chemical features. We found out that besides the Cottrell-cloud phenomenon, many other segregation states exist.”, explains Xuyang (Rhett) Zhou, first author of the paper and postdoctoral researcher at the MPIE funded by the Alexander von Humboldt Foundation. The experiments and simulations revealed that segregation is determined not only by the defect structure but also by the defects’ topological arrangement in the lattice. In addition, the magnitude of segregation depends on the type of host defect. “We managed to quantitatively resolve the defect types and segregation chemistry from both the experiments and the simulations, revealing that each defect configuration shows its own specific segregation state, often deviating substantially from the Cottrell theory.”, says Dr. Jaber Mianroodi, group head at the MPIE who contributed to the simulations done for this paper.

“The different states of local chemical composition at defects can have a significant impact on the mechanical and chemical behaviour of materials. Our findings pave the way for tuning local chemical-structural defect states for the design of specific properties.”, states Prof. Dierk Raabe, director at the MPIE. The scientists are now heading to understand the influence of segregated solute at defects on material properties.

Their preliminary results suggest, for example, that the enrichment of gold at defects can postpone the loss of platinum during oxygen reduction reaction, thereby enhancing the robustness of the material’s catalytic performance. The goal is to establish a fundamental understanding of the structure-composition-property relationship to enable the development of advanced materials though defect engineering.

Wissenschaftliche Ansprechpartner:

Dr. X. Zhou; x.zhou@mpie.de

Dr. J. Mianroodi, j.mianroodi@mpie.de

Originalpublikation:

X. Zhou, J.R. Mianroodi, A. Kwiatkowski da Silva, T. Koenig, G.B. Thompson, P. Shanthraj, D. Ponge, B. Gault, B. Svendsen, D. Raabe: The hidden structure dependence of the chemical life of dislocations. In: Science Advances, 16 Apr 2021, Vol. 7, no. 16, eabf0563, DOI: 10.1126/sciadv.abf0563

Weitere Informationen:

https://www.mpie.de/4542668/the-hidden-chemical-life-of-defects

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Compact LCOS Microdisplay with Fast CMOS Backplane

…for High-Speed Light Modulation. Researchers from the Fraunhofer Institute for Photonic Microsystems IPMS, in collaboration with HOLOEYE Photonics AG, have developed a compact LCOS microdisplay with high refresh rates that…

New perspectives for material detection

CRC MARIE enters third funding period: A major success for terahertz research: Scientists at the University of Duisburg-Essen and the Ruhr University Bochum have been researching mobile material detection since…

CD Laboratory at TU Graz Researches New Semiconductor Materials

Using energy- and resource-saving methods, a research team at the Institute of Inorganic Chemistry at TU Graz aims to produce high-quality doped silicon layers for the electronics and solar industries….