A new soft electronic material for human-machine-interfacing

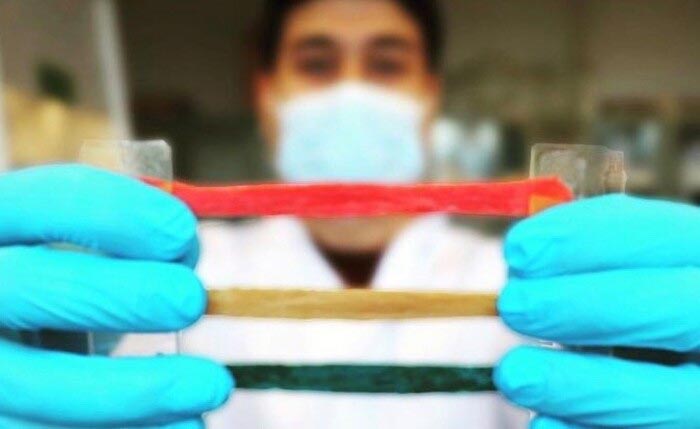

Ph.D. student Morteza Alehosseini, DTU Health Tech, demonstrates that CareGum is very stretchable.

Credit: DTU Health Tech

Researchers at DTU Health Tech have developed a new material that can facilitate a near-perfect merger between machines and the human body for diagnostics and treatment.

A DTU research team consisting of Malgorzata Gosia Pierchala, Firoz Babu Kadumundi, and Mehdi Mehrali from #TeamBioEngine headed by Alireza Dolatshahi-Pirouz, have developed a new material – CareGum – that among other things has potential for monitoring motor impairment associated with neurological disorders such as Parkinson’s.

A green material with many properties

The CareGum property portfolio is incredibly broad with feats such as skin-like softness, it is stretchable up to 30,000 % and has self-healing capacities reminiscent of that of natural tissues. It is printable, moldable, and electrically conductive. Notably, the electrical conductivity enables the material to respond to external stimuli and deliver information to an electronic circuit, while the printing capacity opens up avenues for the custom manufacture of personalized bioelectronics.

It is generated via a scalable route devoid of complicated and time-consuming chemical procedures. In brief, it consists of a biodegradable polymeric matrix, clay nanotubes extracted from the underground, and a super reactive green cross-linker (tannic acid) that undoubtedly has stimulated the taste buds of many wine drinkers, since it gives it its bitter and fruity taste. Therefore, CareGum is essentially a green, recyclable, and low-cost sensor (140 USD/Kg).

Diagnostics and treatment perspectives

Associate Professor Alireza Dolatshahi-Pirouz explains: “CareGums are essentially Bio-Adaptable Cyborg Sensors. They can link or merge synthetic materials and machinery with the human body in a seamless and comfortable manner for both diagnosis and treatment. We envision that our new material could be used to decipher the complex motion patterns that come into play in various movements or motions such as real-time monitoring of those, who are immobilized because of disease. We have for example shown that CareGum can be 3D printed to a sleeve of stretchable fabric to monitor movements of the hand.”

The research team is currently working with the next version of the material, which will be able to monitor pH and temperature changes as well as important disease biomarkers, allowing for even further human-machine interaction.

“The body is highly combinatorial from a material point-of-view. Take for instance skin. It is one material, but yet, it can do so much with a broad range of properties including flexibility, self-healing capacity as well as temperature, mechanical strain, and perception sensing capacity. CareGum is exactly like that. It’s soft, flexible, adaptable, healable, and almost animated. CareGum is not dead material. It is alive. It lives…” Associate Professor Alireza Dolatshahi-Pirouz enthuses.

All latest news from the category: Medical Engineering

The development of medical equipment, products and technical procedures is characterized by high research and development costs in a variety of fields related to the study of human medicine.

innovations-report provides informative and stimulating reports and articles on topics ranging from imaging processes, cell and tissue techniques, optical techniques, implants, orthopedic aids, clinical and medical office equipment, dialysis systems and x-ray/radiation monitoring devices to endoscopy, ultrasound, surgical techniques, and dental materials.

Newest articles

NASA: Mystery of life’s handedness deepens

The mystery of why life uses molecules with specific orientations has deepened with a NASA-funded discovery that RNA — a key molecule thought to have potentially held the instructions for…

What are the effects of historic lithium mining on water quality?

Study reveals low levels of common contaminants but high levels of other elements in waters associated with an abandoned lithium mine. Lithium ore and mining waste from a historic lithium…

Quantum-inspired design boosts efficiency of heat-to-electricity conversion

Rice engineers take unconventional route to improving thermophotovoltaic systems. Researchers at Rice University have found a new way to improve a key element of thermophotovoltaic (TPV) systems, which convert heat…