Low concentrations of CO2→CO direct conversion technology

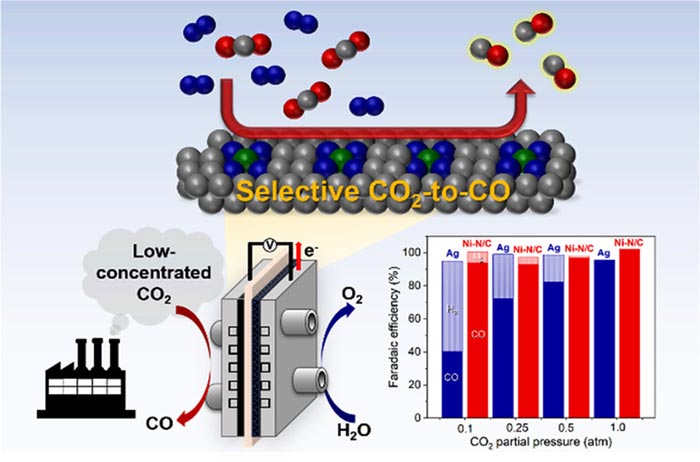

Developed extrinsic operating conditions controlling the water transfer from the anolyte to the catalyst layer and improved CO selectivity at low CO2 concentrations in the MEA electrolyzer.

Credit: Korea Institute of Science and Technology (KIST)

Flue gas level low-concentration carbon dioxide high-efficiency conversion made possible. Economically feasible electrochemical carbon dioxide conversion achieved.

A Korean research team has developed a technology that can produce carbon monoxide (CO), which has various applications in industry, by direct conversion of flue gas level low-concentration carbon dioxide (CO2). The Korean Institute of Science and Technology (KIST, President Seok-jin Yoon) announced that the research team of Dr. Da Hye Won and Dr. Ung Lee at Clean Energy Research Center and Professor Yun Jeong Hwang at Seoul National University (President Se-jung Oh) has developed a catalyst and a operating process that can produce CO with high efficiency using flue gas level low-concentration CO2.

CO2 conversion to valuable chemicals is one of the most promising strategies for mitigating the global climate crisis and developing new processes for chemical production.However, these technologies require supply of high-concentration CO2 gas. This is because CO2 is chemically very stable, which makes it difficult to convert CO2 to other chemicals, and a high-concentration CO2 supply is needed to increase the reaction rate and the efficiency. Actual flue gas from industrial plants typically contains 10% CO2 along with other emissions such as nitrogen, oxygen, and nitrogen oxide; however, until now, it has not been possible to achieve enough efficiency from this low concentration of CO2.

As a catalyst for electrochemical conversion of CO2 to CO, Ag is mainly used due to its high CO productivity. Commercial Ag nanopacticles produce 95% CO when high-concentration CO2 (99.99%) is used, while it produces 40% CO and 60% hydrogen when low-concentration (10%) CO2 is used.

The research team at KIST has developed a nickel single-atom catalyst that can inhibit hydrogen production and increase CO production efficiency. Transition metals such as iron and nickel could not be used as CO2 conversion catalysts due to their lower reactivities than those of noble metals; however, the recent finding that using transition metals in single-atom structure can achieve high CO productivity motivated the team to develop the new catalyst. The team also developed an optimized operating techniques for advanced CO2 conversion system that can directly convert gas-fed low-concentration CO2 by using both experimental and computational simulation methods.

The developed nickel single-atom catalyst can produce 93% CO with low-concentration (10%) CO2, and it is also economically feasible by using non-precious materials composed of nickel and carbon compared to noble Ag catalyst.

Dr. Da Hye Won at KIST said, “The developed catalyst and the operating techniques can be widely applied in electro-chemical conversion systems utilizing low-concentration carbon dioxide. And we are also in the process of development of various technologies to use the flue gas directly without any additional conditioning process to achieve the economic feasibility of electro-chemical carbon dioxide conversion technology.”

The Korea Institute of Science and Technology(KIST). Founded as the first multidisciplinary government-funded research institute in Korea, KIST established a national development strategy based on science and technology and disseminated various essential industrial technologies. Now, half a century later, KIST is elevating Korea’s status in the field of science and technology through world-leading fundamental technology R&D. Looking to the future, KIST will continue to strive to be a premier research institute, pursuing a brighter future for Korea and all of humanity.

Journal: ACS Energy Letters

DOI: 10.1021/acsenergylett.1c01797

Article Title: Electrocatalytic Reduction of Low Concentrations of CO2 Gas in a Membrane Electrode Assembly Electrolyzer

Article Publication Date: 10-Sep-2021

All latest news from the category: Interdisciplinary Research

News and developments from the field of interdisciplinary research.

Among other topics, you can find stimulating reports and articles related to microsystems, emotions research, futures research and stratospheric research.

Newest articles

Largest magnetic anisotropy of a molecule measured at BESSY II

At the Berlin synchrotron radiation source BESSY II, the largest magnetic anisotropy of a single molecule ever measured experimentally has been determined. The larger this anisotropy is, the better a…

Breaking boundaries: Researchers isolate quantum coherence in classical light systems

LSU quantum researchers uncover hidden quantum behaviors within classical light, which could make quantum technologies robust. Understanding the boundary between classical and quantum physics has long been a central question…

MRI-first strategy for prostate cancer detection proves to be safe

Active monitoring is a sufficiently safe option when prostate MRI findings are negative. There are several strategies for the early detection of prostate cancer. The first step is often a…