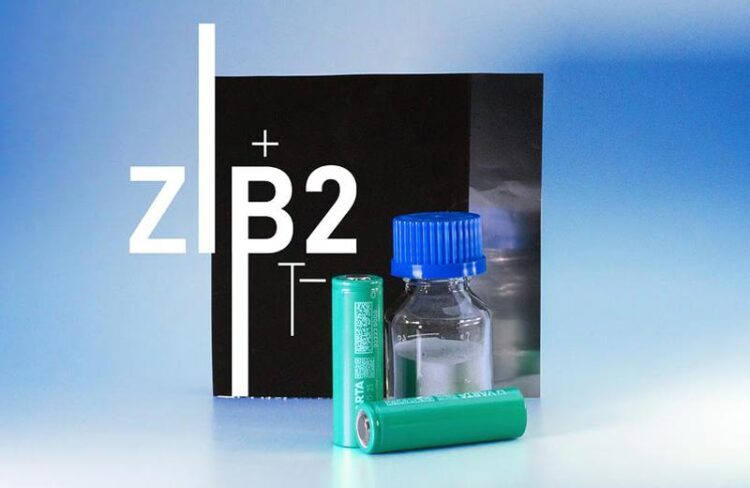

Sustainable zinc-ion batteries for the energy transition

Design and development of materials and components for sustainable zinc-ion battery cell manufacturing.

© Fraunhofer IFAM

– research project aims for rapid industrial implementation.

Stationary energy storage systems aiming to relieve the public power grid during peak loads play an important role in the implementation the energy transition. Zinc-ion batteries have been the focus of attention for these and other applications for some time – but so far without commercial success. The BMBF-funded research project “Aqueous Zinc-Ion Batteries ZIB2” is now investigating how an industrial implementation can be successful. The use of non-critical, low-cost materials, an increase in efficiency and extension of cycle life as well as the application of industrial cell designs are the central scientific goals of the project.

Aqueous zinc-ion batteries (ZIB) are often referred to as a green energy storage technology because their cell chemistry is based on sufficiently available zinc. The batteries are considered safe to operate, environmentally friendly and economical. Additionally, there is no risk of explosion or fire because water is an essential component of the cell. Although ZIB systems have already reached a high level of technological maturity, the technology has not yet been able to establish itself across broad fields of application compared to the lithium-ion battery (LIB). However, as the demand for sustainable storage technologies continues to grow, alternative systems such as ZIB are increasingly coming into focus. The market launch of zinc-ion technology is being accelerated by the steadily increasing demand for energy storage, the growing shortage of raw materials for established systems, and the desire for greater environmental friendliness and sustainability. Thus, ZIB are changing into a real alternative to the dominant LIB technology, especially in the field of stationary storage.

State-of-the-art and technical challenges of zinc-ion batteries

On the one hand modern zinc ion concepts consist, of a positive electrode with a variety of possible materials such as manganese oxides, vanadium oxides or Prussian blue analogs (PBA) such as copper hexacyanoferrate and, on the other hand, of a negative electrode made of metallic zinc. This is complemented by the use of water as the electrolyte, which immensely increases the intrinsic safety of the ZIB system.

Cost efficiency, economy, safety and sustainability are nowadays the driving forces when it comes to choosing a suitable battery storage system for stationary applications, such as storing surplus solar or wind energy. Unlike established technologies, such as LIB, aqueous zinc-ion systems fully meet the above critical market requirements. Thanks to their high environmental friendliness, the aqueous, non-toxic electrolytes and materials used, the high specific power essential for power grid applications, and the low cost due to the good availability of zinc, ZIBs represent an attractive approach to solving the current and future energy storage problem.

The PBA cathode materials addressed in ZIB2 are characterized by their low energy losses and their ability to charge and discharge fast. This makes them particularly relevant for applications in the stationary energy storage sector, where it is necessary to react quickly to any peak loads in the power grid in order to avoid widespread power outages. Another advantage of PBA cathode materials is their simple, scalable and cost-effective synthesis. In the course of rapid commercialization, large quantities of electrodes can thus be produced and further processed into numerous cells according to the demand. A major disadvantage of PBA systems has been their short lifetime of only 300 cycles (charge and discharge). However, project partners of the ZIB2 consortium have already been able to increase the lifetime of PBA-based ZIBs to 800 cycles by cleverly modifying the respective PBA structure. Additional strategies are being pursued in the current project to increase the performance of the ZIB technology and thus enable rapid use of the developed cells in real application scenarios.

Improved cycle life and efficiency due to innovative materials and cell concepts

To further increase the lifetime and efficiency of zinc-ion batteries, the project partners are synthesizing, characterizing and optimizing novel materials, both for the anode and the cathode. In addition, new electrolyte compositions are being produced and studied in detail. Furthermore, the aging mechanisms occurring at the electrodes, which can impair the long cycle life of the battery cells, will be identified and analyzed. This will provide clues for further optimization of the interaction between the electrodes and the electrolyte. After the identification of promising materials and material combinations, various industry-oriented cell designs will be developed, produced and tested in order to determine the optimal design for a final, production-ready product. Different manufacturing processes will also be addressed, like printing of ZIBs. Finally, all starting materials, cell components and manufacturing processes will be subjected to a detailed economic and ecological evaluation in order to determine the full market potential of this novel battery technology and to prove the economic viability and environmental friendliness of the ZIB system.

Background information

The ZIB2 project is coordinated by Varta Microbattery GmbH, which aims to scale up the cell design and promotes the industry-oriented demonstrator. The electrochemistry of the active materials is being analyzed and studied at the University of Bremen. GRILLO-Werke AG is contributing its expertise on zinc materials and their use as anodes. Fraunhofer IFAM manufactures the Prussian blue analog cathode materials on a large scale and develops the electrode formulations and coatings. The adaptation of the Zn-based electrolytes is developed by the E-Lyte Innovations GmbH. Battronics GmbH addresses aging models, cost considerations and value creation.

Funding

Federal Ministry of Education and Research BMBF

Funding code: FKZ: 03XP0523

Project duration: 2.2023-1.2026

Project sponsors: Projektträger Jülich (PtJ)

Project partner

Varta Microbattery GmbH (Coordinator)

University of Bremen, Department of Energy Storage and Energy Conversion Systems

GRILLO-Werke AG

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

E-Lyte Innovations GmbH

Battronics GmbH

Wissenschaftliche Ansprechpartner:

Dr. Daniela Fenske | Phone +49 171 976 75 81 | daniela.fenske@ifam.fraunhofer.de | Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM | Wiener Straße 12 | 28359 Bremen | www.ifam.fraunhofer.de

Dr. Christian Kucznierz | Phone +49 7961 921-2727 | christian.kucznierz@varta-ag.com | VARTA AG | VARTA-Platz 1 | 73479 Ellwangen | www.varta-ag.com

Weitere Informationen:

Further information regarding Fraunhofer IFAM

http://www.ifam.fraunhofer.de

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

New model of neuronal circuit provides insight on eye movement

Working with week-old zebrafish larva, researchers at Weill Cornell Medicine and colleagues decoded how the connections formed by a network of neurons in the brainstem guide the fishes’ gaze. The…

Innovative protocol maps NMDA receptors in Alzheimer’s-Affected brains

Researchers from the Institute for Neurosciences (IN), a joint center of the Miguel Hernández University of Elche (UMH) and the Spanish National Research Council (CSIC), who are also part of…

New insights into sleep

…uncover key mechanisms related to cognitive function. Discovery suggests broad implications for giving brain a boost. While it’s well known that sleep enhances cognitive performance, the underlying neural mechanisms, particularly…