Fast, precise, and wear-free

Micro-drilling with the laser is especially interesting for sound-absorbing cladding elements, for example in aviation.

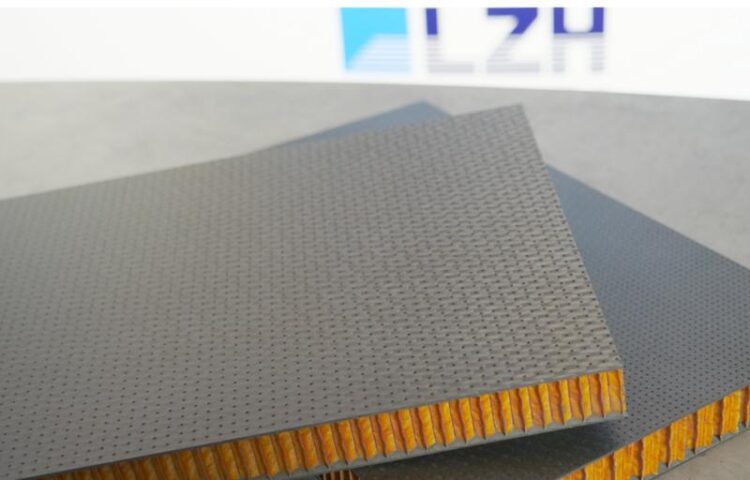

Photo: LZH

LZH develops process for laser drilling CFRP.

Scientists of Laser Zentrum Hannover e.V. (LZH) have developed an automated process for laser drilling that facilitates the machining of carbon fiber-reinforced plastics (CFRP). This is particularly interesting for lightweight construction and sound insulation.

Holes can be drilled quickly and automatically in CFRP and sandwich materials using laser technology. Photo: LZH

Composite materials such as carbon fiber-reinforced plastics (CFRP) are excellent for lightweight construction and are used, among other things, in automotive and aircraft construction. To simplify the machining of CFRP and sandwich materials, scientists from LZH, together with INVENT GmbH and KMS Technology Center GmbH, have developed an innovative process with associated system setup.

Simultaneous drilling with small diameters

In this process, a laser beam is split into partial beams by specially designed diffractive optical elements, so that it hits multiple locations on the material and generates multiple bores simultaneously. Ideally, this can be done with up to 25 partial beams, reducing the drilling time to only a 25th of the original time, resulting in less than a tenth of a second per bore – a value that cannot be achieved with conventional methods even for larger bores.

With this process, the scientists were able to create bores with diameters ranging from only 1.2 mm to 0.25 mm. This makes them smaller than bores that can currently be implemented with conventional mechanical methods in sandwich and CFRP materials. The use of optomechanics manufactured by KMS Technology Center GmbH also enables high flexibility in bore diameter and pattern without the need for tool changes.

Sound insulation in lightweight construction as an application area

Micro-drilling with lasers is particularly interesting in aviation. To reduce aircraft noise emissions, sound-absorbing cladding elements are used to line engines, for example. Such components are often made of CFRP or CFRP sandwich materials and then provided with many small bores over a large area.

Micro-drilling with lasers is particularly suitable for these so-called acoustic drilling because laser drilling is contactless and therefore force- and wear-free. This eliminates high costs due to tool wear and quality problems due to dull drills. In acoustic tests, project partner INVENT GmbH evaluated the sound damping properties of the laser-drilled sandwich panels as very good.

About miBoS

The project “Micro-drilling of Sandwich Materials: Development of a Laser Process” (miBoS) is funded by the Federal Ministry of Economics and Climate Protection under grant number 20T1926C.

Weitere Informationen:

https://www.lzh.de/en/press-releases/2024/fast-precise-and-wear-free-lzh-develop…

Media Contact

All latest news from the category: Machine Engineering

Machine engineering is one of Germany’s key industries. The importance of this segment has led to the creation of new university degree programs in fields such as production and logistics, process engineering, vehicle/automotive engineering, production engineering and aerospace engineering among others.

innovations-report offers informative reports and articles covering technologies such as automation, motion, power train, energy, conveyor, plastics, lightweight construction, logistics/warehousing, measurement systems, machine tools and control engineering.

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…