Want to petrify wood without waiting a few million years? Try this

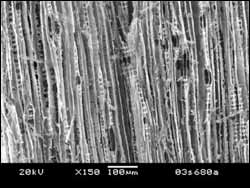

Soaked, Dried & Petrified: An electron microscopic image shows a cross section of wood that was artificially petrified in days, mimicking a natural process that takes millions of years. Materials scientists are interested in the novel properties of ceramics built on wood templates. (Photo credit: Pacific Northwest National Laboratory.)

Pacific Northwest National Laboratory scientists can mineralize wood in record time

California has Silicon Valley. Could a Silicon Forest in Washington be next? A team of materials scientists from Pacific Northwest National Laboratory is on it.

Yongsoon Shin and colleagues at the Department of Energy lab have converted wood to mineral, achieving in days what it takes nature millions of years to do in such places as the Gingko Petrified Forest, an hour up the Columbia River. There, trees likely felled in a cataclysmic eruption and, buried without oxygen beneath lava, leached out their woody compounds and sponged up the soil’s minerals over the eons.

Shin’s petrified wood journey began in a less dramatic fashion, a few minutes away at Lowe’s, Shin’s group reports in the current issue of the journal Advanced Materials, in the do-it-yourselfer chain’s lumberyard,. There they picked up their raw material: pine and poplar boards. Back at PNNL, they gave a 1 centimeter cube of wood a two-day acid bath, soaked it in a silica solution for two more (for best results, repeat this step up to three times), air-dried it, popped it into an argon-filled furnace gradually cranked up to 1,400 degrees centigrade to cook for two hours, then let cool in argon to room temperature.

Presto. Instant petrified wood, the silica taking up permanent residence with the carbon left in the cellulose to form a new silicon carbide, or SiC, ceramic. The material “replicates exactly the wood architecture,” according to Shin.

Although SiC chips are unlikely to replace computer chips, materials scientists are interested in the novel properties of ceramics built on templates of wood and, in Shin’s lab, other natural materials such as pollen and rice hulls. The intricate network of microchannels and pores in plant matter provide enormous surfaces–in wood, 1 gram of material flattened out would cover a football field–that may prove useful in industrial chemical separations or filtering pollutants from gaseous effluents.

The acid-leaching method yields an identical, positive reproduction of the wood. If Shin wants to capture a negative impression, he can alter the pH to favor the base end of the scale.

“The positive replica is a lot better in terms of surface area and uniformity,” Shin said. “Negative forms collapse easily, but it is possible to make fiber-type materials,” where the minerals fill in wood-grain openings.

Media Contact

More Information:

http://www.pnl.govAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…