A concrete solution

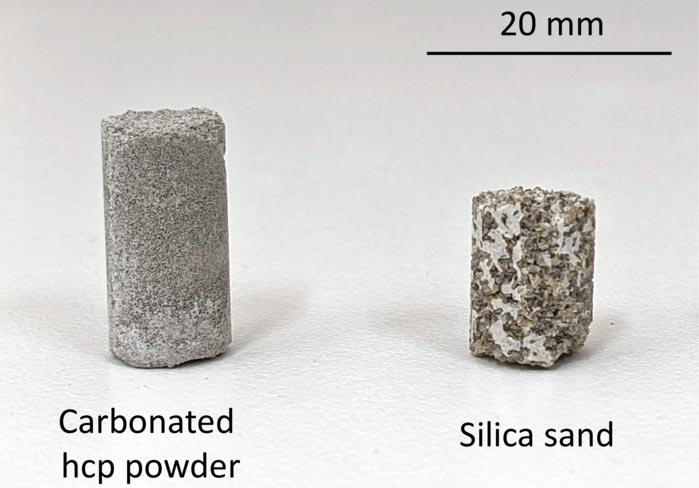

Two samples of calcium carbonate concrete, one using hardened cement paste (left) and the other using silica sand. Both raw materials are common construction and demolition waste products.

Credit: © 2021 Maruyama et al.

Recycled concrete and CO2 from the air are made into a new building material.

A new kind of concrete could reduce emissions from the construction industry. Calcium carbonate concrete is made from waste concrete and carbon dioxide from the air or industrial exhaust gases. It shows promise as a future construction material, especially in places where natural resources are limited.

The modern world is built from concrete. Every tall building in every city on Earth uses the durable and versatile material to give it shape and strength. The concrete industry therefore is enormous, and this comes at a cost: It is estimated that around 7% of the world’s carbon dioxide emissions come from the manufacture and use of cement, the main component of concrete. And a large proportion of this 7% is due to the necessary use of calcium, which is usually obtained by burning limestone.

A new way to reduce emissions levels caused by concrete use has been proposed and proven to work by Professor Ippei Maruyama and C4S (Calcium Carbonate Circulation System for Construction) project manager Professor Takafumi Noguchi, both from the Department of Architecture at the University of Tokyo. They have found a way to take waste concrete and captured carbon dioxide, and combine them in a novel process into a usable form of concrete called calcium carbonate concrete.

Inspired by the way some aquatic organisms harden into fossils over time, Maruyama wondered if the same process that forms hard calcium carbonate deposits from dead organic matter could be applied to concrete. Calcium is essential for the reaction between cement and water to form concrete, and Maruyama saw this as an opportunity to investigate a less carbon-intensive way of performing the same function.

“Our concept is to acquire calcium from discarded concrete, which is otherwise going to waste,” said Maruyama. “We combine this with carbon dioxide from industrial exhaust or even from the air. And we do this at much lower temperatures than those used to extract calcium from limestone at present.”

Calcium carbonate is a very stable material, so makes for a durable construction material. And the ability to recycle large quantities of material and waste is a great benefit. However, calcium carbonate concrete cannot replace typical concrete at present. It is not quite as strong as typical concrete, though for some construction projects, such as small houses, this would not be a problem. Also at present, only small blocks a few centimeters in length have been made.

“It is exciting to make progress in this area, but there are still many challenges to overcome,” said Noguchi. “As well as increasing the strength and size limits of calcium carbonate concrete, it would be even better if we could further reduce the energy use of the production process. However, we hope that in the coming decades, carbon-neutral calcium carbonate concrete will become the mainstream type of concrete and will be one of the solutions to climate change.”

Journal article

Ippei Maruyama, Wataru Kotaka, Bui Ngoc Kien, Ryo Kurihara, Manabu Kanematsu, Hikotsugu Hyodo, Hiroshi Hirao, Ryoma Kitagaki, Masaki Tamura, Masato Tsujino, Satoshi Fujimoto and Takafumi Noguchi, “A New concept of calcium carbonate concrete using demolished concrete and CO2” Journal of Advanced Concrete Technology, DOI: 10.3151/jact.19.1052

https://doi.org/10.3151/jact.19.1052

Funding

This research was funded by the NEDO Moonshot project, C4S Research and Development Project, Calcium Carbonate Circulation System for Construction

Links

Graduate School of Engineering – https://www.t.u-tokyo.ac.jp/soee/index.html

Department of Architecture – https://arch.t.u-tokyo.ac.jp/

Research contacts

Professor Ippei Maruyama – i.maruyama@bme.arch.t.u-tokyo.ac.jp

Professor Takafumi Noguchi, C4S project manager – noguchi@bme.arch.t.u-tokyo.ac.jp

Department of Architecture, Graduate School of Engineering,

The University of Tokyo, 7-3-1 Hongo, Bunkyo-ku, Tokyo 113-8656, Japan

Tel: +81(0)-3-5841-6196/6198

Press Contact

Mr. Rohan Mehra

Division for Strategic Public Relations, The University of Tokyo

7-3-1 Hongo, Bunkyo-ku, Tokyo 113-8654, Japan

Email: press-releases.adm@gs.mail.u-tokyo.ac.jp

About the University of Tokyo

The University of Tokyo is Japan’s leading university and one of the world’s top research universities. The vast research output of some 6,000 researchers is published in the world’s top journals across the arts and sciences. Our vibrant student body of around 15,000 undergraduate and 15,000 graduate students includes over 4,000 international students. Find out more at www.u-tokyo.ac.jp/en/ or follow us on Twitter at @UTokyo_News_en.

Journal: Journal of Advanced Concrete Technology

DOI: 10.3151/jact.19.1052

Method of Research: Experimental study

Subject of Research: Not applicable

Article Title: A New concept of calcium carbonate concrete using demolished concrete and CO2

Article Publication Date: 8-Oct-2021

All latest news from the category: Architecture and Construction

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…