Robot inspects concrete garage floors and bridge roadways for damage

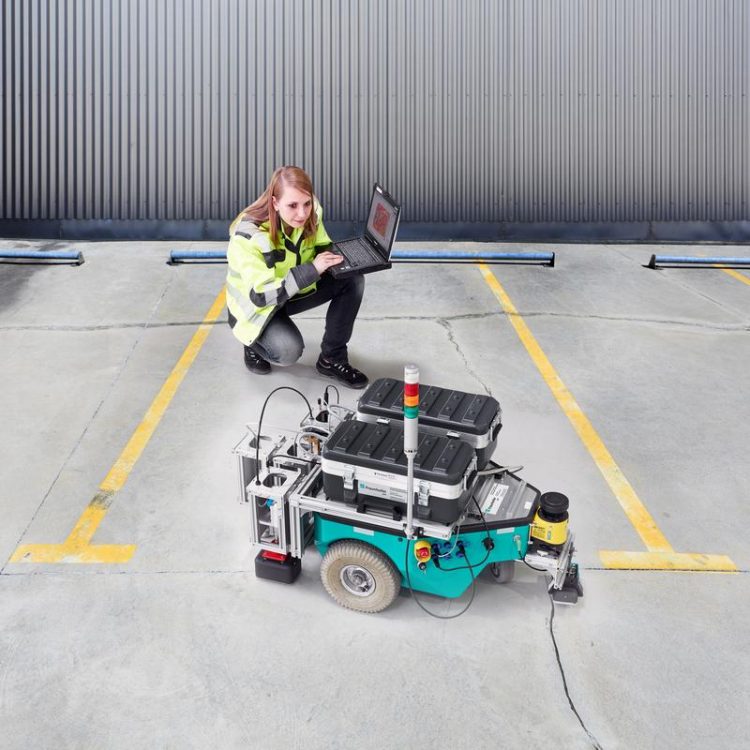

BetoScan®: robot that can inspect concrete floors for damage in parking garages. Uwe Bellhäuser

From April 13 to April 17 at the Hannover Messe (hall 2, exhibit booth C16), engineers from the Fraunhofer Institute for Nondestructive Testing IZFP will be presenting BetoScan®, a robot capable of inspecting concrete surfaces as large as several hundred square meters on its own. Only one person is required to operate and monitor the system.

Employees from the Fraunhofer Institute for Nondestructive Testing IZFP, together with the German Federal Institute for Materials Research and Testing (BAM) and industry experts, have joined forces to develop a robot platform that can independently scan and inspect large areas of concrete for damage without impacting the surface. Referred to as BetoScan®, the system was designed as a self-propelled, self-navigating robot platform for nondestructive inspection sensors.

“Our robot can easily inspect parking garage surfaces as large as several hundred square meters in one day and requires only one person to operate and monitor the system,” explains Ralf Moryson, an engineer at Fraunhofer IZFP. The robot can independently scan obstacle-free concrete surfaces using a preselected grid while simultaneously recording the data acquired by the various inspection processes.

The cascadable mounting system for the inspection sensors permits the utilization and quick replacement of commercially-available sensors. When selecting the sensors for the system, the developers focused on automated logging of the measurement results, as well as on the use of well-established inspection methods.

This provides an extensive inspection capability that ensures the timely identification of surface corrosion. While scanning the surface, the system also creates a survey of the structure being inspected.

“A major advantage of our robot system is the integrated combination of different nondestructive testing processes. The sensors analyze factors such as moisture content and the thickness of the concrete, as well as the depth and condition of the reinforcement,” adds Moryson. The complete measurement results can be graphically displayed. Rounding out this development is the ability to administer the measurement data.

The BetoScan® project was funded through the German Federal Ministry for Economic Affairs and Energy InnoNet program.

Media Contact

All latest news from the category: Architecture and Construction

Newest articles

Innovative 3D printed scaffolds offer new hope for bone healing

Researchers at the Institute for Bioengineering of Catalonia have developed novel 3D printed PLA-CaP scaffolds that promote blood vessel formation, ensuring better healing and regeneration of bone tissue. Bone is…

The surprising role of gut infection in Alzheimer’s disease

ASU- and Banner Alzheimer’s Institute-led study implicates link between a common virus and the disease, which travels from the gut to the brain and may be a target for antiviral…

Molecular gardening: New enzymes discovered for protein modification pruning

How deubiquitinases USP53 and USP54 cleave long polyubiquitin chains and how the former is linked to liver disease in children. Deubiquitinases (DUBs) are enzymes used by cells to trim protein…