Microscanner mirrors replace human vision

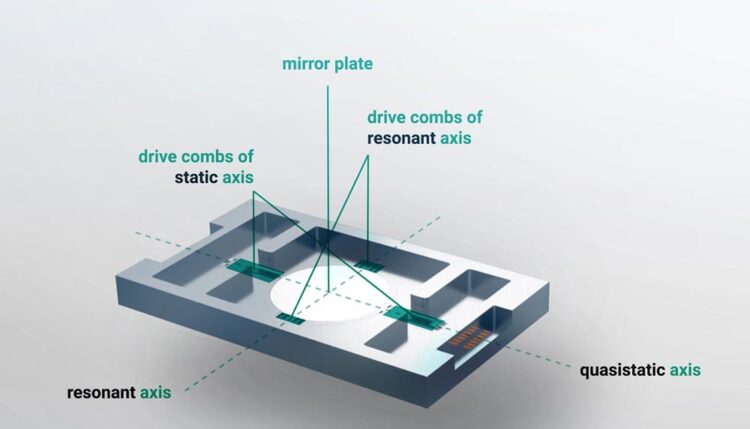

A MEMS mirror from Fraunhofer IPMS.

© Fraunhofer IPMS

Enhanced safety for autonomous driving

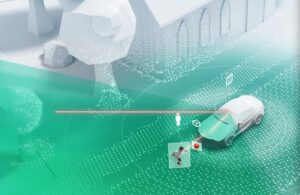

In autonomous vehicles, it is advanced technology that takes the wheel, allowing passengers to sit back and enjoy the ride. Yet such systems have to meet stringent safety standards. For example, an autonomous vehicle must be able to recognize obstacles and other hazards – and apply the brakes in an emergency. Such a vehicle could be equipped with a new microscanner mirror from the Fraunhofer Institute for Photonic Microsystems IPMS. This performs a 3D scan of the vehicle surroundings to a range of over 200 meters. When integrated within a LiDAR system, it can obviate the need for human vision and thereby make a key contribution to the safety of autonomous driving.

Today’s vehicles already feature a variety of advanced driver-assistance systems. In coming years, it will become compulsory to install emergency systems such as evasive steering support in new vehicles, thus paving the way for the advent of autonomous driving. Yet even in coming vehicle generations, humans will still be expected to keep an eye on their surroundings and react in dangerous situations. This could well change, however, with the introduction of LiDAR (light detection and ranging) systems, which measure the distance between the vehicle and other objects. Such systems are able to scan the surrounding area for potential hazards and thereby replace the human eye. As such, they mark a decisive step on the way towards safe autonomous driving.

© Fraunhofer IPMS

A team of researchers at Fraunhofer IPMS in Dresden has now developed a new type of microscanner mirror, which forms a key element of LiDAR systems that are capable of 3D digital vision. This component is used to steer the laser that generates a 3D scan of the surrounding area. AEye, a specialist for LiDAR systems in autonomous vehicles, is already using the microscanner mirror in its 4Sight LiDAR sensor. “With our technology platform, we’re able to meet design specifications for new microscanners suitable for use with LiDAR,” explains Dr. Jan Grahmann, research associate at Fraunhofer IPMS.

“LiDAR systems are able to scan the surrounding area in three dimensions and therefore detect pedestrians, cyclists or other vehicles. Our MEMS mirror splits the laser beam in two dimensions and focuses the light on the object that is being measured. By measuring the time of flight of the reflected light, it is also possible to determine the distance to the object as a third dimension.”

In detail, the process is as follows: light from a laser diode or other laser source is directed at a microscanner mirror installed in the transmitter of the LiDAR system. The mirror scans the surrounding area in two dimensions. To determine the third dimension, the light reflected from the object is captured by a LiDAR sensor. Here, the following applies: the more light captured by the sensor, the more accurately the distance to the object can be determined. This is a task performed by an evaluation algorithm. The distance to each scanned position in the vehicle surroundings generates a 3D point cloud that represents the LiDAR field of vision.

Robust, proof against material fatigue, resistant to temperature and shock

The MEMS scanner is made of monocrystalline silicon, a material with several advantages: it is not only robust and proof against material fatigue but it has a high temperature and shock resistance. The silicon has a reflective coating that intensifies the reflection of the light. Thanks to positioning technology integrated in the chip, it is possible to continuously track where the mirror steers the laser beam and which position is being measured. This in turn enables correction to the point of operation. In the vehicle, the LiDAR sensor is generally mounted behind the rear-view mirror, from where it directly scans the surrounding area though the windshield. This system can be used to perform a 3D scan in the infrared range, thereby supplementing the vision of the driver or passengers.

“Our MEMS mirrors are typically up to 5 millimeters in size,” says Grahmann. “For spe-cialized applications, larger mirrors are an option; but with increasing size, you lose the benefits of MEMS. Alongside the microscanner mirrors, we also supply the requisite packaging and the drive electronics. All components can be designed to customer specifications, thereby guaranteeing that they can be integrated in different LiDAR systems. We also develop, for example, MEMS scanners for head-mounted displays and industrial robots.”

The microscanner mirrors from Fraunhofer IPMS function, for example, at wavelengths typical for LiDAR applications – 905 to 1,550 nanometers. The size of aperture has a major impact on operating range. With the smart LiDAR sensors from AEye, operating ranges of over 200 meters are possible. AEye has successfully completed testing of the MEMS scanners from Fraunhofer IPMS, which are used in its LiDAR system.

“At present, advanced driver-assistance systems featuring LiDAR technology are still about providing greater comfort and enhanced safety. There are five levels of autono-mous driving, each of which involves a different degree of driver invention. Now, there’s still some way to go before fully autonomous driving becomes a reality, but our technology will help advance this process,” says Grahmann. The next step will be to produce the microscanner mirrors in larger volumes and to prepare the technology for mass production.

Weitere Informationen:

https://www.fraunhofer.de/en/press/research-news/2021/january-2021/microscanner-…

Media Contact

All latest news from the category: Automotive Engineering

Automotive Engineering highlights issues related to automobile manufacturing – including vehicle parts and accessories – and the environmental impact and safety of automotive products, production facilities and manufacturing processes.

innovations-report offers stimulating reports and articles on a variety of topics ranging from automobile fuel cells, hybrid technologies, energy saving vehicles and carbon particle filters to engine and brake technologies, driving safety and assistance systems.

Newest articles

Innovative 3D printed scaffolds offer new hope for bone healing

Researchers at the Institute for Bioengineering of Catalonia have developed novel 3D printed PLA-CaP scaffolds that promote blood vessel formation, ensuring better healing and regeneration of bone tissue. Bone is…

The surprising role of gut infection in Alzheimer’s disease

ASU- and Banner Alzheimer’s Institute-led study implicates link between a common virus and the disease, which travels from the gut to the brain and may be a target for antiviral…

Molecular gardening: New enzymes discovered for protein modification pruning

How deubiquitinases USP53 and USP54 cleave long polyubiquitin chains and how the former is linked to liver disease in children. Deubiquitinases (DUBs) are enzymes used by cells to trim protein…