The Drive for Digital Cars

The global Siemens research department is working with partners to develop new information and communications technology for future electric cars.

Cornel Klein, a Siemens software engineer, steers a compact yellow van through a city. After a left turn, he stops at a traffic light before proceeding carefully through a large puddle. Although one might think this is a simple everyday situation, it is actually nothing of the kind, because the vehicle Klein is steering is actually one meter above the ground. In fact, the van’s tires are spinning in mid-air. As a result, their whirring electric motors aren’t moving the vehicle the slightest bit forward.

The van is mounted on a test rig in Siemens Corporate Technology’s research center southeast of Munich. In front of the windshield, Klein sees a city projected on a screen. When he accelerates or steers, it causes external motors that are connected to the van’s axles to respond, thus helping to simulate a wide variety of driving situations..

Automotive Operating System

The van, which was built by German electric vehicle manufacturer StreetScooter, is a key component of the Robust and Reliable Automotive Computing Environment for Future eCars (RACE) research project, which was launched in 2012 and is headed by Siemens. Funded by Germany’s Federal Ministry for Economic Affairs and Energy, the project has eight partner organizations from research and industry. In addition to Siemens and StreetScooter, partners include the fortiss Institute at the Technical University of Munich and the RWTH Aachen University. Their goal: Nothing less than to bring about a revolution in vehicle technology in order to create a completely digital car.

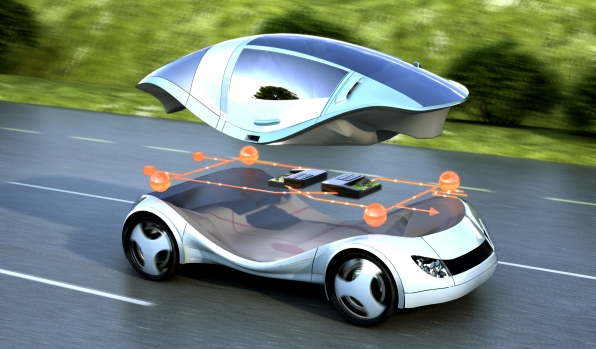

RACE intends to replace traditional decentralized electronics with a kind of automotive operating system on which new apps could be installed just as they are on smartphones. Moreover, vehicles’ steering, acceleration, and braking systems would no longer be controlled by mechanical rods, cables, and shafts, but by RACE-controlled motors. “Remember the memory typewriters of the 1980s?” asks Klein, who manages the RACE project. “The PC swept that technology from the market. RACE might trigger a similar change.”

Plug-and-Play Car

Although the creation of an overarching software platform might not sound exceptionally challenging, it’s a tall order when it comes to cars. If you look underneath the hood or behind the body panels of one of today’s mid-range automobiles, you will see innumerable cables as well as more than 70 electronic control units for systems such as the anti-lock braking (ABS) and automatic windshield wipers, as well as dozens of sensors that all have to harmonize with one another. Added to this are hundreds of sub-functions, which run on these systems and exchange data. It’s very difficult and often totally uneconomical to retrofit new functions into a car after it has left the factory. Not only do technicians have to install many new cables, they also have to update the display systems and the vehicle’s existing electronics.

RACE, by contrast, is a computer architecture that combines the strengths of the centralized and decentralized approaches in order to control cars. Engineers participating in RACE developed the new architecture between 2012 and 2014. The resulting StreetScooter delivery vehicle represents the first step toward using this new approach in a mass-production automobile. Together with their colleagues from StreetScooter, the project’s engineers first replaced the vehicle’s standard control unit with a special RACE control unit that regulates the drive system and the energy recovery process. Although the new software platformhas not yet been completed , it demonstrates that such an approach can be integrated into vehicles equipped with a traditional system architecture. In acknowledgement of this fact, the electric StreetScooter has been named “Evolution” by the project’s participants.

Accelerated Development

But the system’s development will obviously not stop here. By 2016, engineers intend to reduce the number of electronic control units in the StreetScooter — something that will also be done in other vehicles over the long term, regardless of whether they are equipped with combustion engines or electric motors. Ultimately, the control units’ tasks will be performed by only a few computers. However, due to safety considerations, these computers will have redundant backups. . RACE’s standardized software platform enables engineers to upload a wide variety of functions onto a vehicle according to the plug-and-play principle. Examples of such functions range from a more efficient battery control system to an app that intensifies the stereo system’s bass.

What’s more, the platform would make it easy for technicians to retrofit sensors for features such as reversing cameras, and install new actuators for systems such as motors, lamps, and displays. All of these systems would be connected to a vehicle’s RACE computers via a standardized bus system. As a result, vehicles could be quickly and inexpensively updated after only a brief test phase. Vehicle development times would be shortened as well. Prof. Achim Kampker, CEO of StreetScooter and Head of the Chair of Production Engineering of E-Mobility Components at RWTH University Aachen, says, “We believe that if you combine our vehicles’ modular design with RACE technology, you could cut the development time for a new vehicle model in half while greatly reducing development costs.”

“We believe that if you combine RACE with our vehicles’ modular design, you could cut the development time for a new vehicle model in half while greatly reducing development costs.”

Participating RACE researchers are using an unusual research vehicle — the Roding Roadster Electric — to demonstrate what the future might eventually look like. The vehicle is an experimental electric sports car that was built by a car development firm in Bavaria and is now parked next to the Siemens test rig in a workshop. In this car, the RACE operating system not only unifies the electronics, it also eliminates all of the mechanical systems between the steering wheel, brake pedal, and gas pedal, on the one hand, and the motor and tires on the other. This setup is known as “drive-by-wire” and is analogous to the fly-by-wire computer control system used in airplanes. Pressure sensors in the brake and gas pedals measure how strongly they are being depressed. A computer uses this information to forward appropriate digital commands to the brakes and the motor. In addition, the steering wheel does not control the Roding’s tires via the steering column, but through an actuator that is operated by means of digital signals.

These are by no means all the innovative features that the Roding contains. For example, the vehicle’s motor has been incorporated directly into the wheels in the form of a wheel-hub drive in the rear axle. Another innovation is that the car’s battery pack doesn’t need a power socket to recharge. That’s because induction is used to wirelessly recharge the vehicle when it is parked above a charging plate on the garage floor. Currently, no mass-production vehicle boasts such a combination of innovations as the Roding. It is therefore not surprising that it has been named “Revolution.” However, the Roding won’t be mass produced, as it is merely a test platform for RACE technology.

Firewall for Cars

But what would happen if a hacker used an infected update to freeze the onboard computer or to suddenly order an emergency braking maneuver? This scenario doesn’t particularly worry the RACE project’s software security expert, Prof. Manfred Broy from the Technical University of Munich. “In principle, we already know how to design secure software updates,” he says. “You need to install firewalls, introduce clear security requirements, and develop a general security concept for the onboard automotive systems.”

Automobiles are becoming more and more digitized, and RACE technology is being seamlessly integrated into more of the automotive industry’s future innovations. One example of this is autonomous driving, the groundwork for which is being laid by assistance systems for cruise control, proximity warning, lane recognition, and automatic parking. RACE is also well adapted to the “Vehicle Internet,” which will be rolled out in the coming years to facilitate communication between automobiles and infrastructures such as roadside transmission stations. The RACE project extends beyond the automotive industry, however, because its associated technology will help to simplify the control systems of complex machines such as rail vehicles.

Since the research project was wrapped up last year, work has focused on the continued integration of RACE architecture into the StreetScooter, replacing complex mechanical steering and braking systems with a few computers and drive-by-wire technology. “If everything goes as planned — and we are very optimistic that it will — the first RACE-controlled StreetScooter vehicles will be rolling off production lines as early as 2016,” says Klein.

Dr. Hubertus Breuer

Media Contact

More Information:

http://www.siemens.comAll latest news from the category: Automotive Engineering

Automotive Engineering highlights issues related to automobile manufacturing – including vehicle parts and accessories – and the environmental impact and safety of automotive products, production facilities and manufacturing processes.

innovations-report offers stimulating reports and articles on a variety of topics ranging from automobile fuel cells, hybrid technologies, energy saving vehicles and carbon particle filters to engine and brake technologies, driving safety and assistance systems.

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…