Canadoil Plate Ltd are First to Purchase the Siemens VAI Smart Shear

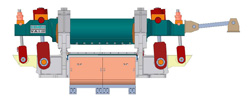

The hydraulically operated Smart Shear from Siemens

Canadoil Plate Ltd from Thailand have become the first company to purchase the new Siemens VAI Smart Shear Technology, a new hydraulically operated cross-cut plate shear that provides improved cutting quality.

The two Smart Shears that Canadoil have purchased will form part of the shearline included in the recent order awarded to Siemens VAI for a new 5 Meter Plate Mill facility. The mill will be designed mainly for the production of plates for high grade pipe, pressure vessels and structural steels for the energy industry. The whole project, including the mill, shearline and Smart Shear equipment is scheduled to start operation in 2010.

Located in Bangkok, Thailand, Canadoil Plate Ltd. is part of the Canadoil Group, a leading manufacturer of components for the energy industry including main transmission pipelines for the oil and gas industry as well as specialty piping components for the power and water treatment industries.

The Group specializes in the manufacture of a very wide range of pipes and fittings with diameters from 1/2” to 120” in all types of ferrous and non-ferrous materials. Canadoil also manufactures static equipment such as pressure vessels, reactors, filters, heat exchangers, launcher receivers and slug catchers and all of the prefabricated piping spools and modules required to create large scale industrial plants in the petrochemical, power, water treatment and mining industries.

Canadoil’s CEO, Giacomo Sozzi stated that “this order is a further expression of confidence in Siemens VAI’s capabilities to bring technological advances to its customers that provide lasting competitive advantages. The Smart Shear differentiates our product offerings in the market, especially for higher specification plates to serve customers requiring applications in severe conditions which are Canadoil’s key focus. The entire 5 meter Plate Mill project is based on a long term partnership concept with Siemens VAI in which both companies will share know-how openly and thus draw long term benefits from this trusting exchange.”

Due to the rising demand for high-strength types of steel and for plates with a greater thickness and width, the requirements placed on conventional plate mill shears have increased dramatically. The shears and their components are being subjected to much greater forces. At the same time, uneven cuts or imprecisely cut edges have to be avoided. The mechanically operated shears available on the market are at the limit of their capabilities, particularly with regard to reducing deflections; which are a significant factor in cutting quality.

Compared to conventional mechanical shears, the hydraulically operated Smart Shear has been designed to minimize deflections and more accurately achieve a rolling blade action, thereby improving cut quality, and enabling greater flexibility; maintenance is also simplified.

In the case of Smart Shear, servo-controlled hydraulic cylinders are used on both sides of the shears in order to operate the top blade. A rolling cut action is therefore possible without the gears, shafts and cranks needed for mechanical shears. This reduces the number of moving parts and thus susceptibility to wear as well as the need for maintenance. Simulations have demonstrated a considerably better control of cutting angle and blade overlap compared to mechanical shears. Careful design ensures that the blade overlap is kept almost constant over the entire width of the plate. This, again, improves the cutting quality. Moreover, the blade overlap can easily be adapted to the optimum value for the respective plate thickness and width by means of the control software.

In order to improve operational flexibility, the Smart Shear is equipped with two pairs of hydraulic cylinders. Both pairs of cylinders are used at the same time for cutting high-strength or thick plate. When thin plate or lower-strength plate has to be cut, only one pair of cylinders is used, in this way the hydraulic system can be minimised. The cutting speed can easily be adapted to the requirements in each case and a higher cutting speed than the conventional mechanical shears can be achieved on thin products.

The design of the machine is such that the side frames are not subjected to the vertical component of cutting force. Therefore they only have to withstand the much lower horizontal blade forces and thus can be much lighter.

Further information about solutions for steel works, rolling mills and processing lines is available at http://www.siemens.com/metals

The Siemens Industry Sector (Erlangen, Germany) is the world's leading supplier of production, transportation and building systems. Integrated hardware and software technologies combined with comprehensive industry-specific solutions enable Siemens to enhance the productivity and efficiency of its customers in industry and infrastructure. The Sector comprises six Divisions: Building Technologies, Industry Automation, Industry Solutions, Mobility, Drive Technologies and Osram. In fiscal 2007 (ended September 30), Siemens Industry generated sales of approximately EUR40 billion (pro forma, unconsolidated) with around 209,000 employees worldwide.

With the business activities of Siemens VAI Metal Technologies, (Linz, Austria), Siemens Water Technologies (Warrendale, Pa., U.S.A.), and Industry Technologies, (Erlangen, Germany), the Siemens Industry Solutions Division (Erlangen, Germany) is one of the world's leading solution and service providers for industrial and infrastructure facilities. Using its own products, systems and process technologies, Industry Solutions develops and builds plants for end customers, commissions them and provides support during their entire life cycle.

Media Contact

All latest news from the category: Corporate News

Newest articles

Largest magnetic anisotropy of a molecule measured at BESSY II

At the Berlin synchrotron radiation source BESSY II, the largest magnetic anisotropy of a single molecule ever measured experimentally has been determined. The larger this anisotropy is, the better a…

Breaking boundaries: Researchers isolate quantum coherence in classical light systems

LSU quantum researchers uncover hidden quantum behaviors within classical light, which could make quantum technologies robust. Understanding the boundary between classical and quantum physics has long been a central question…

MRI-first strategy for prostate cancer detection proves to be safe

Active monitoring is a sufficiently safe option when prostate MRI findings are negative. There are several strategies for the early detection of prostate cancer. The first step is often a…