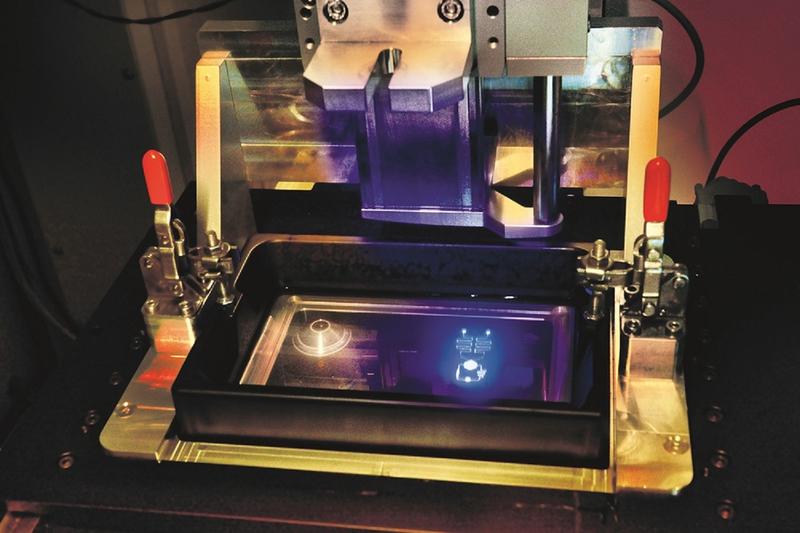

Together with industrial partners, the Fraunhofer Institute for Laser Technology ILT has developed a novel system for producing high-resolution microcomponents by photo-crosslinking. Thanks to their work in the project “High productivity and detail accuracy in additive manufacturing by combining UV polymerization and multiphoton polymerization – HoPro-3D,” polymer microstructures can now be produced economically and customized in one machine. The experts at the Fraunhofer ILT worked together with LightFab GmbH from Aachen, Bartels Mikrotechnik GmbH from Dortmund and Miltenyi Biotec GmbH…

Jellyfish-like soft gripper mimics the mechanics of curly hair. If you’ve ever played the claw game at an arcade, you know how hard it is to grab and hold onto objects using robotics grippers. Imagine how much more nerve-wracking that game would be if, instead of plush stuffed animals, you were trying to grab a fragile piece of endangered coral or a priceless artifact from a sunken ship. Most of today’s robotic grippers rely on embedded sensors, complex feedback loops,…

… to achieve carbon neutrality. KIMM develops 30% hydrogen combustor for domestic gas turbine. Cooperation with KIMM, Doosan Enerbility and Korea East-West Power Company to demonstrate the combustor on power plant by 2027. An eco-friendly hydrogen combustor for domestic gas turbine that reduces carbon dioxide emissions has been developed and will be undergoing field test. The Korea Institute of Machinery and Materials (President Sang Jin Park, hereafter referred to as the KIMM), an institute under the jurisdiction of the Ministry…

Smart sensors that are wirelessly attached to the component, improve the understanding and control of production processes so that processes can be flexibly monitored and adaptively controlled. What sounds like a far-off vision of the future is already being implemented by the Fraunhofer Institute for Production Technology IPT in Aachen, Germany: Together with seven industrial partners, the researchers have designed an intelligent and flexible process control system that can process large amounts of data and transmit it almost instantaneously using…

The world’s whitest paint – seen in this year’s edition of Guinness World Records and “The Late Show With Stephen Colbert” – keeps surfaces so cool that it could reduce the need for air conditioning. Now the Purdue University researchers who created the paint have developed a new formulation that is thinner and lighter – ideal for radiating heat away from cars, trains and airplanes. “I’ve been contacted by everyone from spacecraft manufacturers to architects to companies that make clothes and shoes,” said Xiulin Ruan,…

To respond individual customer requirements and to meet social and political responsibility, a research project was carried out in cooperation between Ansmann AG and Fraunhofer Institute für Structural Durability and System Reliability LBF. Aim was the development of natural fibre-reinforced plastics for usage in Li-ion battery housings. Fraunhofer Researchers will present more details at the Fraunhofer booth, Hall 7, SC01, at the “K-Messe” in Düsseldorf from October 19 to 26. Current trends demonstrate the growing importance of sustainable products and…

Automation solutions on a 1:1 scale for sustainable rail vehicle construction from Fraunhofer IFAM in Stade, Germany – InnoTrans 2022. InnoTrans 2022 l Hall 23 l Booth 240 l The Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM in Stade will be presenting automation solutions on a 1:1 scale for sustainable rail vehicle construction for the first time as part of the leading International Trade Fair for Transport Technology from September 20 to 23, 2022 in Berlin, Germany. Research…

Service robotics from Fraunhofer IFAM in Stade, Germany at InnoTrans 2022. Applied research at InnoTrans 2022 in Berlin, Germany: As part of the “Fraunhofer vs. Corona” program, the automation and production technology experts at Fraunhofer IFAM in Stade, together with project partners, developed a prototype mobile robot platform which uses a lightweight robot and steam cleaner to clean and disinfect surfaces of objects in public transport (PT) vehicles with constant quality in an environmentally friendly manner (https://s.fhg.de/FuEMobDiStade; video). The robot,…

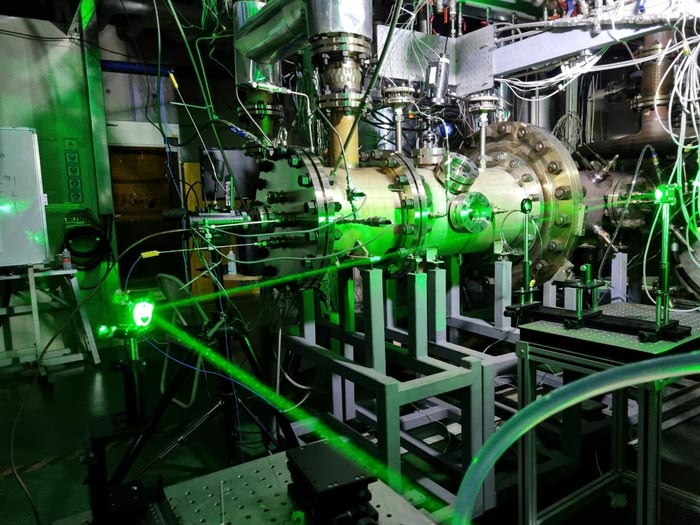

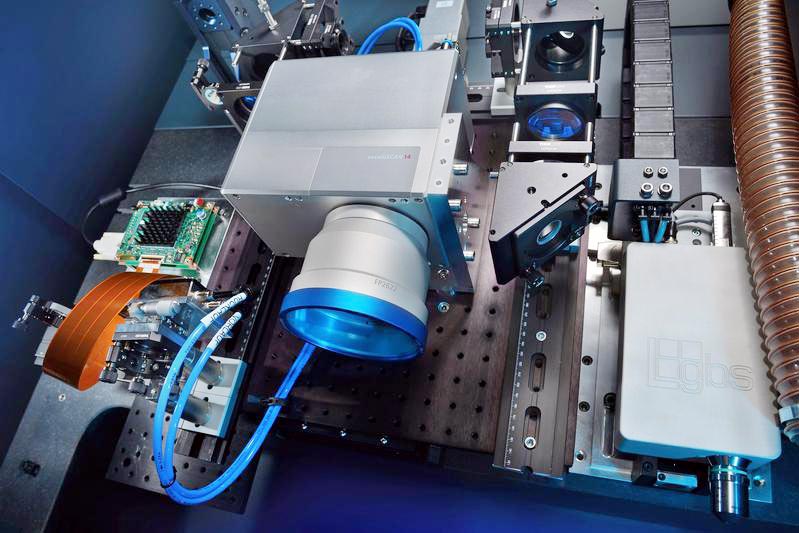

… in industrial high-power USP processes. Together with Hamamatsu, the Fraunhofer Institute for Laser Technology ILT in Aachen has set up an application lab for advanced laser material processing with ultrashort pulsed (USP) laser radiation. In Aachen, the partners jointly developed an industrial processing SLM-head that can use customized, dynamic beam shaping combined with large laser average output powers for a wide range of applications. The applied, new Spatial Light Modulator from Hamamatsu can be operated up to 150 watts…

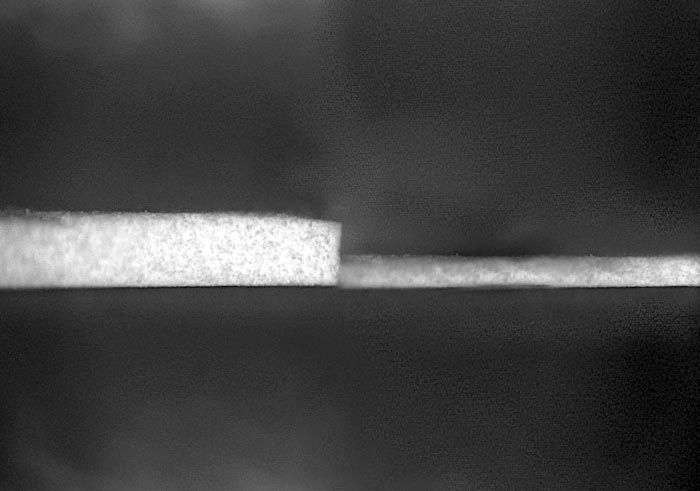

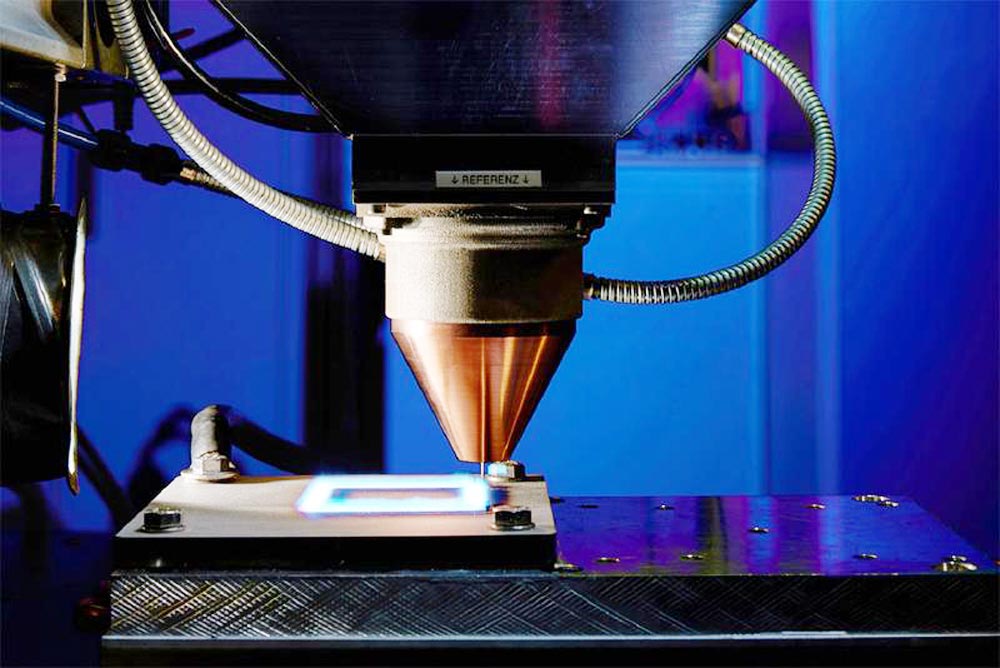

An example of hybrid technology in its purest form has been developed and built by the Fraunhofer ILT for the DVS research project “KoaxHybrid.” In Aachen, the institute engineers have developed a new optical system with glass substrates and an arc torch which unites metal shielding gas (MSG) welding and laser material deposition with an annular beam, thus creating a completely new process. Interested parties can find out how the COLLAR Hybrid process can be used to increase the welding…

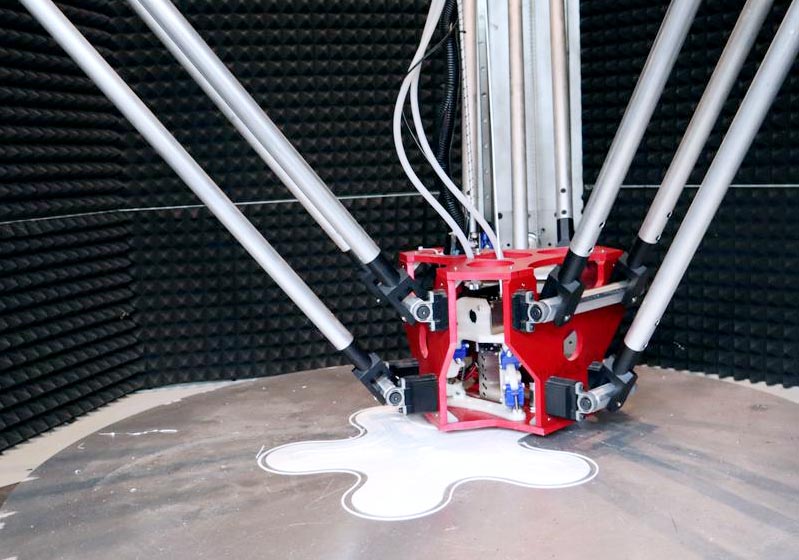

Making the construction of prototypes more efficient, cost-effective, faster and flexible – this will be possible with the world’s largest industrial delta 3D printer. The four-meter-high machine was developed by Professor Yilmaz Uygun’s research group at Jacobs University Bremen. The project, supported by the Kieserling Foundation, exhibits promising potential for industrial application and further research and cooperation opportunities for the university in Bremen-Nord. In industries such as spare parts management, prototype construction, and mechanical and plant engineering, individualized parts are…

The new air-powered hand provides a lightweight, low-maintenance and easy-to-use body-powered prosthetic option particularly well suited for children and those in low and middle-income countries. A revolutionary new hand prosthesis powered and controlled by the user’s breathing has been developed by researchers at the University of Oxford. The simple lightweight device offers an alternative to Bowden cable-driven body-powered prosthetics initially developed in the early 19th century – particularly for those too young or anatomically unsuited to an uncomfortable harness and…

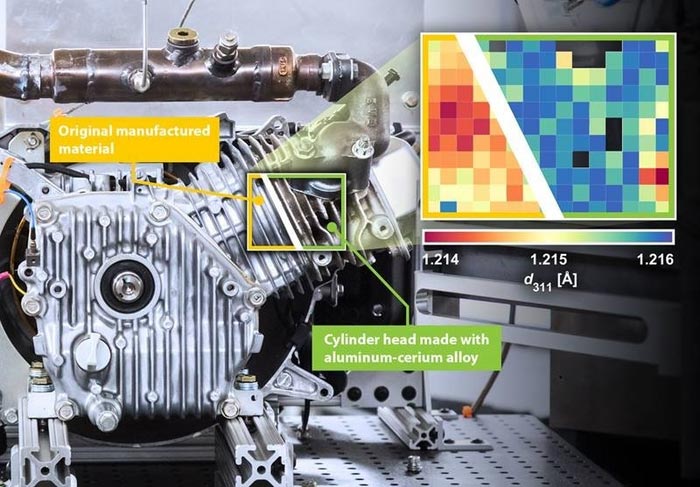

Scientists map atomic-level changes in the components of a running internal combustion engine using neutron techniques. The Science Researchers used neutrons to see how a new aluminum-cerium (AlCe) alloy behaves under the high temperatures and pressures inside an operating internal combustion engine. The technique involves measuring how neutrons scatter when they strike a material. This reveals characteristics deep inside the material’s atomic structure. Researchers fitted an AlCe cylinder head to a commercial engine typically used in construction and industrial applications….

The gravitational constant G determines the strength of gravity – the force that makes apples fall to the ground or pulls the Earth in its orbit around the sun. It is part of Isaac Newton’s law of universal gravitation, which he first formulated more than 300 years ago. The constant cannot be derived mathematically; it has to be determined through experiment. Over the centuries, scientists have conducted numerous experiments to determine the value of G, but the scientific community isn’t…

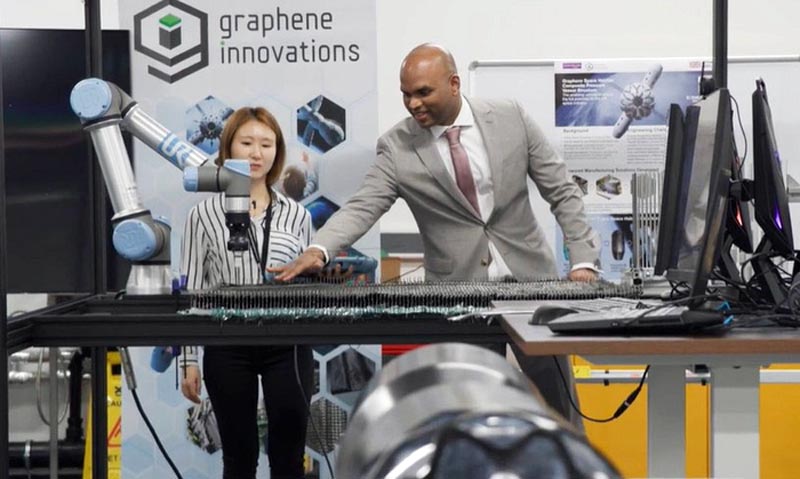

Graphene meets robots as automation is combined with advanced materials. Automated systems combined with new materials will combine as a “dream team” to start a revolution in advanced manufacturing, says a graphene pioneer. Automation and robotic systems are on the brink of transforming the way we all work and live says Dr Vivek Koncherry, who is based at The University of Manchester‘s Graphene Engineering Innovation Centre (GEIC). A UK government report has found that the total economic impact of automation across…

Strong innovations: “Reference-factory.H2”, intelligent machine components in adaptive process chains, human-robot interaction and soft robotics demonstrate solutions for industrial green hydrogen, the factory of the future, household, and nursing. Reference-factory.H2: advancing the industrial production of electrolyzers and fuel cells Anyone who considers acquiring a photovoltaic system for their domestic roof may con-sider a significantly lower budget than ten or fifteen years ago, in spite of current price fluctuations. Highly efficient industrial large series production realizes the lower prices. An individual…