Rice U. engineers improve prelithiation, uncover lithium-trapping mechanism. Silicon anode batteries have the potential to revolutionize energy storage capabilities, which is key to meeting climate goals and unlocking the full potential of electric vehicles. However, the irreversible depletion of lithium ions in silicon anodes puts a major constraint on the development of next-generation lithium-ion batteries. Scientists at Rice University’s George R. Brown School of Engineering have developed a readily scalable method to optimize prelithiation, a process that helps mitigate lithium loss and improves battery…

Fast and effective: The Fraunhofer Institute for Laser Technology ILT has developed a new hybrid process called Simultaneous Machining and Coating (SMaC), which combines laser material deposition with turning, grinding or milling. SMaC allows high-strength coating materials to be applied quickly and efficiently and machined simultaneously. SMaC will enable the industry to produce components with an extended service life and extended operating cycles, an advantage that is highly attractive for the energy industry, the mobility sector and the chemical industry….

New process extracts fragrances. What doesn’t smell good is hard to recycle. This simple rule also applies to the growing volume of plastic waste worldwide. One way to recycle it in an environmentally compatible and climate-friendly manner as high-quality post-consumer recyclates is through improved sorting and reprocessing. Until now, the reduced material quality has considerably limited the reuse of plastic recyclates, and this is mainly due to their odor. Scientists at the Fraunhofer Institute for Structural Durability and System Reliability…

A key ingredient in the manufacture of car tires and sneaker soles could be made sustainably, following new analysis of an old catalytic process. Butadiene, an essential component of synthetic rubber, is currently produced by the petrochemical industry from fossil reserves. But it could be efficiently made in a one-step reaction from renewable ethanol using a modernized version of an unusual old catalyst. “Butadiene is currently produced as a byproduct of the petrochemical industry, which can lead to shortages in…

Modern lightweight construction has already been helping automotive and aerospace industry to save fuel and materials and to reduce environmental impact. Researchers at the Fraunhofer Institute for Material and Beam Technology IWS have recently found a way to transfer such proven design principles to other industries. By using lasers, they weld filigree hollow chamber structures with cover sheets to form lightweight sandwich panels. Such metal structures can be produced particularly efficiently in the roll-to-roll process of the Fraunhofer IWS. The…

Every year on 22 March, World Water Day reminds us of the importance of one of the most important resources of life. Almost two-thirds of our planet is covered with water, but not even three percent is drinkable freshwater. Every day, large quantities of chemicals enter our waters and endanger the health of humans, animals and plants. In addition to pesticides, for example, drug residues also pollute our drinking water. The Leibniz Institute for Plasma Science and Technology (INP) has…

Clean polyester can be separated from mixed waste fabrics by chemical sorting and then converted into original monomers. The apparel industry accounts for 10% of global carbon emissions. The annual amount of fiber production reached 113 million tons in 2021* and the demand is increasing every year. However, almost 90% of post-consumer fiber wastes are disposed of through incineration or in landfills. Among these forms of waste, synthetic fiber has become a major threat to the environment and human health…

This ultrafast infrared spectroscopy method would fulfill many unmet needs in experimental molecular science, revealing various high-speed phenomena in detail. Infrared spectroscopy is a non-invasive tool to identify unknown samples and known chemical substances. It is based on how different molecules interact with infrared light. You may have seen this tool at airports, where they screen for illicit drugs. The technique has many applications: liquid biopsy, environmental gas monitoring, contaminant detection, forensic analyses, exoplanet search, etc. But the traditional infrared spectroscopy…

Identifying defects in fiber composite materials during the production process will be possible in the future thanks to a novel radar method that automatically and non-destructively monitors the manufacturing process of fiber composite materials such as wind turbine rotor blades. Until now, monitoring has consisted of visual inspections. The Fraunhofer Institute for High Frequency Physics and Radar Techniques FHR collaborated with consortium partners Ruhr University Bochum, FH Aachen University of Applied Sciences and Aeroconcept GmbH to develop an innovative method…

… makes further progress. Kraft lignin successfully degraded using a “green” oxidizer. The demand for vanillin vastly outstrips the natural resources of this flavoring agent. A chemical process is thus used to produce the required large quantities of vanillin from petroleum, which is far less expensive than obtaining the substance from fermented genuine vanilla pods. Another alternative is to make vanillin from lignin, a waste product of the wood pulping industry. A team led by Professor Siegfried Waldvogel of Johannes…

New method for temperature determination opens horizon for a multitude of experiments virtually unfeasible up to now. Warm dense matter (WDM) measures thousands of degrees in temperature and is under the pressure of thousands of Earth’s atmospheres. Found in many places throughout the universe, it is expected to have beneficial applications on Earth. However, its investigation is a challenge. Even the temperature of a material under WDM conditions is anything but easy to determine. A team of researchers led by…

Additive manufacturing of tools using a laser powder bed fusion process offers a great number of advantages: It is economical, precise and allows for customized solutions. That said, it can be difficult to determine the optimal process parameters, such as the scan speed or power of the laser. For the first time, researchers at Fraunhofer are now simulating the process at the microstructure level in order to identify direct correlations between the workpiece properties and the selected process parameters. To…

Theory-guided development of an easier, more versatile process for synthesizing unsymmetric ligands provides new avenues of exploration in transitional metal catalysis. Researchers at the Institute for Chemical Reaction Design and Discovery (WPI-ICReDD) have discovered the key to synthesizing a molecular tool that could greatly expand the variety of catalytic reactions possible with transition metals. The team has taken a well-established set of compounds that can be used to make transition metal catalysts and developed a simple, radical-based reaction for creating…

When a surface is getting wet, also the composition of the liquid plays a role in the wetting process. Researchers from the Max Planck Institute for Dynamics and Self-Organization (MPI-DS) found that phase separation within the wetting liquid directly affects the dynamics of spreading. Their findings may be important in various applications, including tissue engineering, biology and semiconductor manufacturing. The study was recently published in the scientific journal PNAS. During phase separation, liquid mixtures of several components turn into an…

Scientists at TU Dresden have succeeded in synthesizing new phosphorescent, platinum-based emitter complexes for high-brightness and long-life OLEDs. The results were published this week in the renowned journal “Chemistry – A European Journal”. Due to their flexible applications and comparatively low manufacturing costs, organic light-emitting diodes (OLEDs) are increasingly conquering the electronics market, for example in cell phone displays or TV screens. Compared with conventional (inorganic) light-emitting diodes, however, OLEDs still lag behind, especially in terms of longevity and luminous…

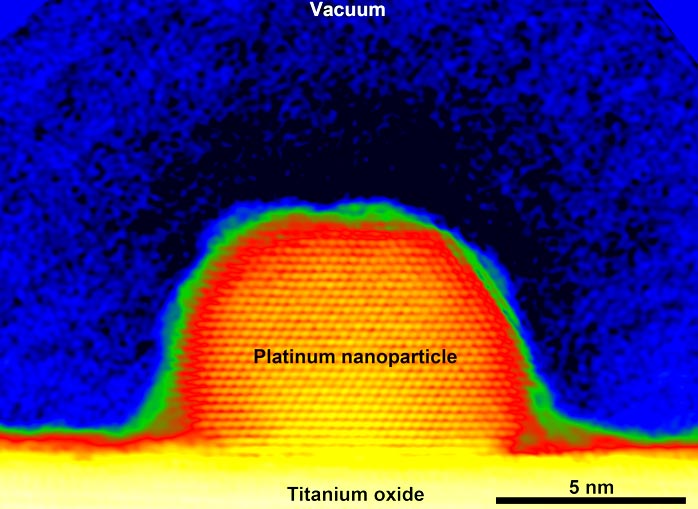

Tenfold improvement in the sensitivity of electron holography reveals the net charge in a single platinum nanoparticle with a precision of just one electron, providing fundamental information for developing future catalysts. If you often find yourself off by one when counting your socks after doing the laundry, you might want to sit down for this. Scientists in Japan have now counted the number of extra—or missing—charges down to a precision of just one electron in single platinum nanoparticles having diameters…