For enhancing flavors, the production of dyes, pharmaceutical products and bio polyesters – succinic acid is a versatile platform chemical. A team led by Elke Nevoigt, Professor of Molecular Biotechnology at Jacobs University Bremen, has developed an economically and ecologically attractive process for the production of succinic acid by more effectively incorporating carbon dioxide (CO2). The German Research Foundation (DFG) is funding the project for another three years. A large number of products in the chemical industry are based on…

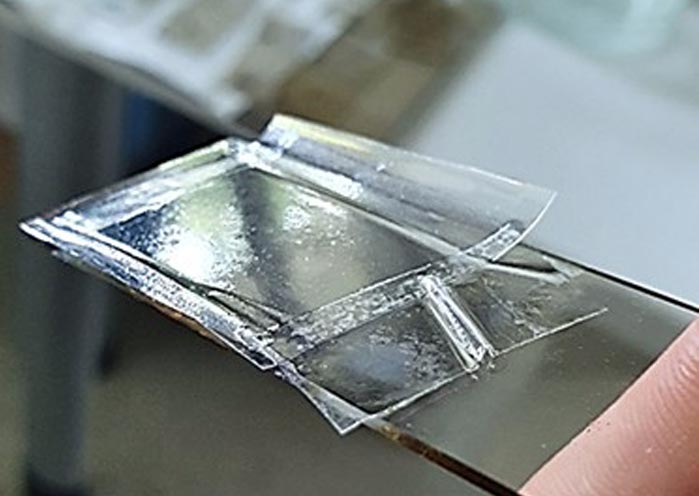

– Low-energy electron beam. Electron beam technology can be used to reliably treat and functionalize surfaces. Now the Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP has succeeded in producing anti-adhesive coatings on plastic film by applying low-energy-accelerated electrons without the use of additional chemical crosslinkers. The institute will present this topic at BIOEurope 2022, from 24 to 26 October 2022, in Leipzig, at Bio-Saxony booth No. 100, among others. Antifouling coatings prevent the growth of undesirable…

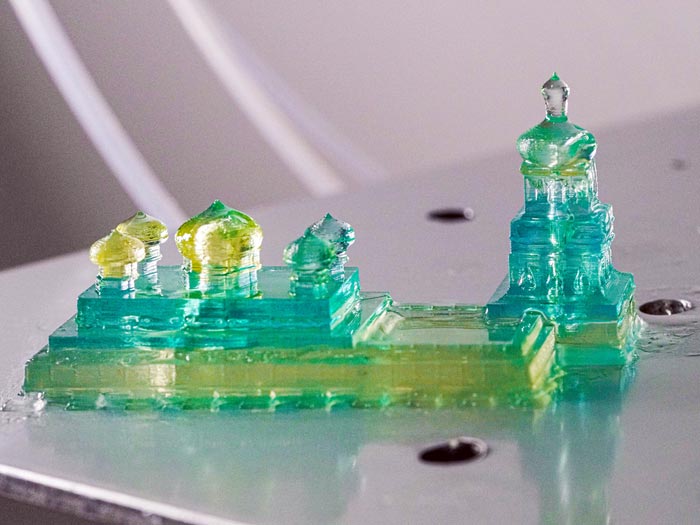

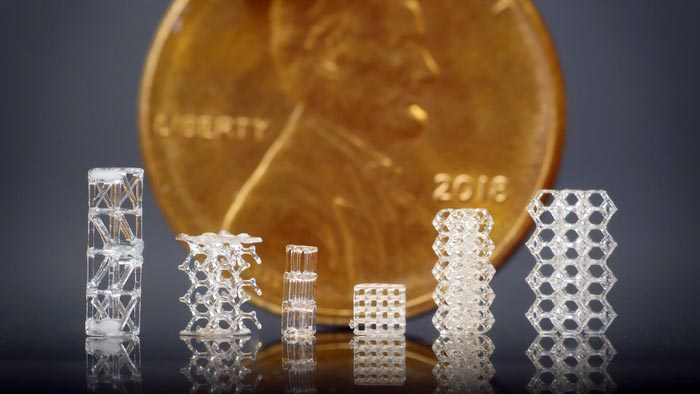

Stanford engineers have designed a method of 3D printing that is 5 to 10 times faster than the quickest high-resolution printer currently available and is capable of using multiple types of resin in a single object. Advancements in 3D printing have made it easier for designers and engineers to customize projects, create physical prototypes at different scales, and produce structures that can’t be made with more traditional manufacturing techniques. But the technology still faces limitations – the process is slow…

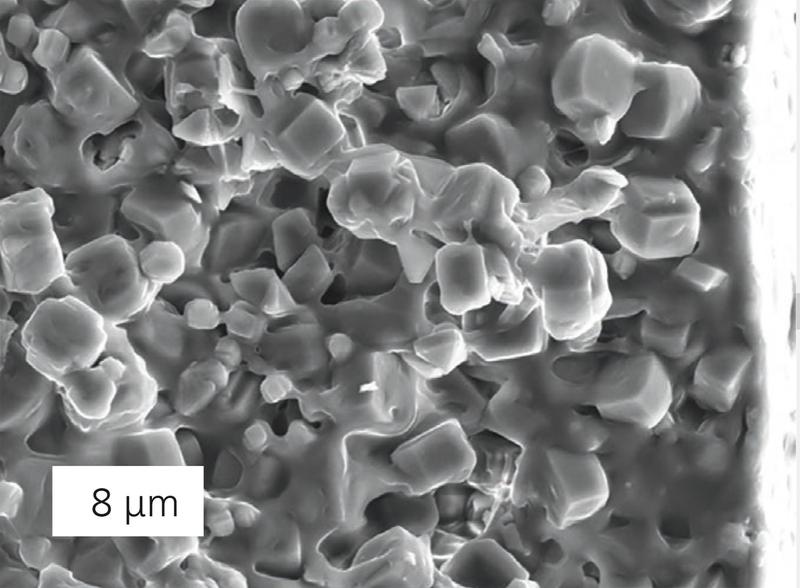

Micro-electromechanical systems (MEMS) have proven themselves a billion times over as sensors in smart cars, cell phones and mini insulin pumps, among other things. To make these MEMS even more powerful in the future, researchers at the Fraunhofer Institute for Laser Technology ILT in Aachen have developed a CMOS-compatible deposition and laser crystallization process in collaboration with the Fraunhofer ISIT and IST. In contrast to other common processes, this new process eliminates the need for wires and solder joints, an…

A new flow-based method harvests a magnesium salt from Sequim seawater. By Beth Mundy Since ancient times, humans have extracted salts, like table salt, from the ocean. While table salt is the easiest to obtain, seawater is a rich source of different minerals, and researchers are exploring which ones they can pull from the ocean. One such mineral, magnesium, is abundant in the sea and increasingly useful on the land. Magnesium has emerging sustainability-related applications, including in carbon capture, low-carbon…

Fraunhofer IWS developed a laser technology to clean and structure surfaces particularly quickly while protecting the environment. Sandblasting – that was yesterday. Laser beams can clean and structure surfaces more precisely, cost-effectively and in environmental friendlier ways than conventional systems. The Fraunhofer Institute for Material and Beam Technology IWS in Dresden has developed the technology “LIGHTblast” for this purpose which is now being transferred to the semiconductor manufacturing, automotive supply and other industries. The Fraunhofer IWS researchers see considerable ecological…

Methanol plays an important role for industry as a commodity chemical and is presently considered one of the key energy carriers in the rising hydrogen economy. However, conventional methanol production from coal and natural gas generates large amounts of greenhouse gas emissions. With the project Carbon2Chem®, partners from industry, research and academia have made it their mission to explore processes for producing methanol from industrial waste gases using the steel industry as an example. For the first time, the long-term…

Sustainable environmental and process engineering. In collaboration with TU Dresden, Fraunhofer researchers have developed a process for obtaining valuable, high-purity ethyl acetate from whey. This can be used, for example, to produce environmentally friendly adhesives, thereby replacing conventional ethyl acetate extracted from fossil-based raw materials. It also eliminates the need for costly disposal of the molasses produced during whey processing. Every day, large quantities of whey are produced as a by-product by the dairy industry. In Germany alone, this amounts…

Out with the silver, in with the copper: The rising price and low availability of raw materials, especially silver, are leading to higher costs in producing photovoltaic modules. Fraunhofer researchers have developed an electroplating process that involves substituting silver, an expensive precious metal, with copper, which is more readily available. They have also succeeded in replacing the polymers that are usually left over after electroplating processes, and are expensive to dispose of, by instead using easily recyclable aluminum for masking….

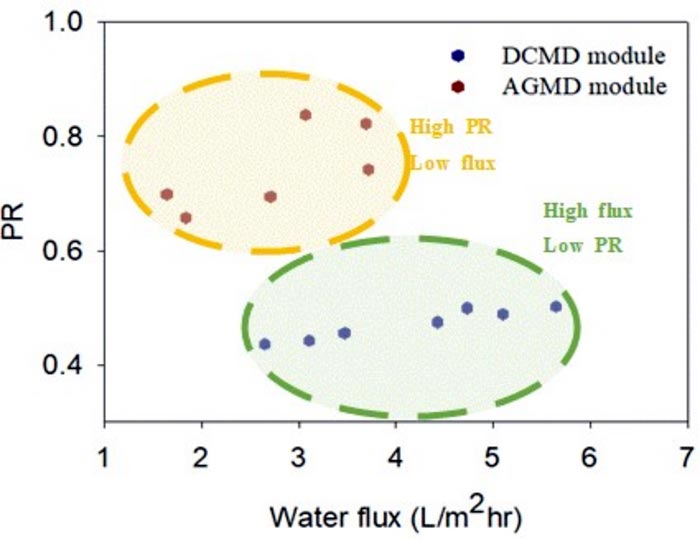

KIST develops membrane distillation methods using hydrothermal and solar energy. The goal is to maximize system efficiency through customized membrane distillation technologies for regional climate characteristics. Clean water is essential for human survival. However, less than 3% of fresh water can be used as drinking water. According to a report published by the World Meteorological Organization, there is scarcity of drinking water for approximately 1 billion people worldwide, which is expected to rise to 1.4 billion by 2050. Seawater desalination…

Nanosheets are finely structured two-dimensional materials and have great potential for innovation. They are fixed on top of each other in layered crystals, and must first be separated from each other so that they can be used, for example, to filter gas mixtures or for efficient gas barriers. A research team at the University of Bayreuth has now developed a gentle, environmentally-friendly process for this difficult process of delamination that can even be used on an industrial scale. This is…

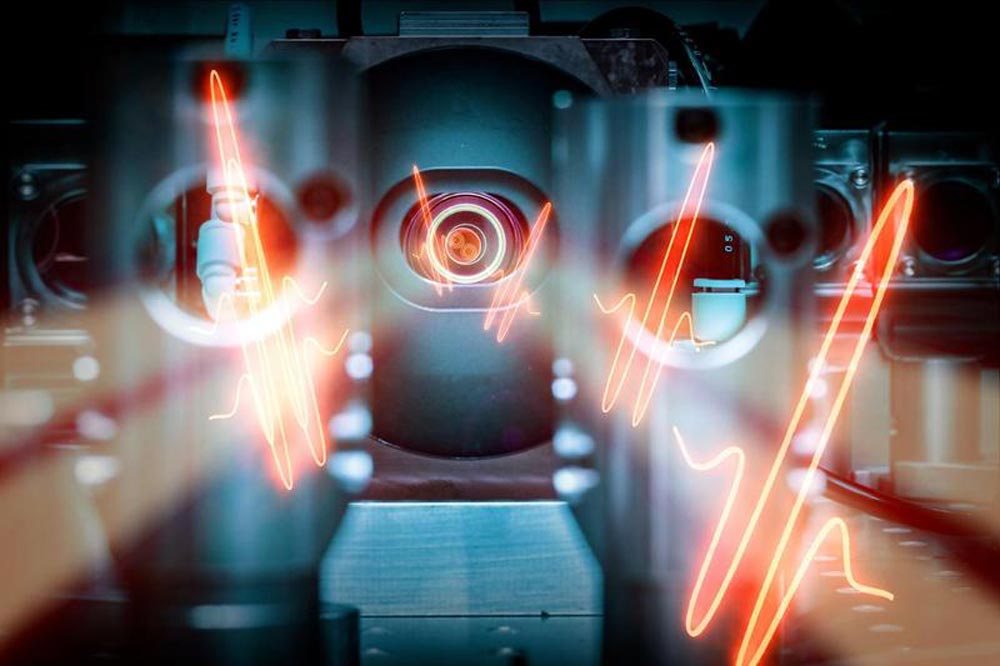

Scientists from Hamburg and Munich developed the world’s most powerful dual-comb spectrometer that paves the way for many applications in atmospheric science and biomedical diagnostics, such as early cancer detection. The work has recently been published in Nature Communications. The core part of the system is a special type of laser-gain medium, a thin-disk, and a unique configuration of the mirrors surrounding this medium, a laser resonator (shown in the illustration). “The key of our dual comb laser source lies…

LZH develops a new process… The Laser Zentrum Hannover (LZH), together with an industrial partner, is developing a laser-assisted metal flux-cored welding process for use underwater. The process aims to facilitate welding work underwater and produce better weld seams. Whether for wind farms, coastal protection structures, or harbors: when technical constructions have to be welded underwater, divers usually do it by manual electrode welding. Scientists of the LZH are now developing an alternative process together with AMT GmbH from Aachen….

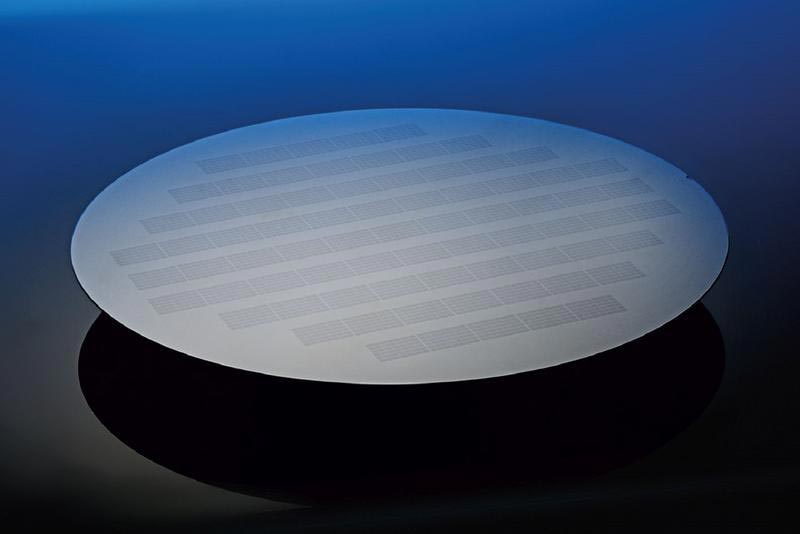

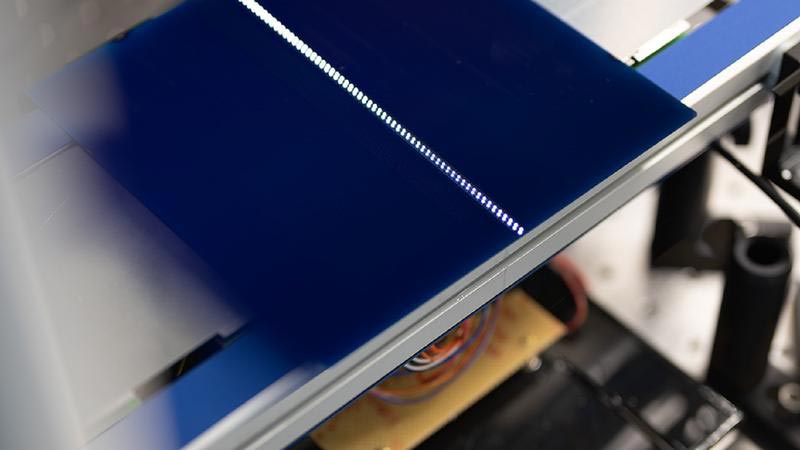

… with Newly Developed On-the-Fly Laser Equipment. In order to be able to manufacture more efficient solar modules, the photovoltaic industry is increasingly switching its production to larger wafer formats. Being able to guarantee the production of these solar cells with an edge length of up to 210 millimeters with consistent quality and cycle rate poses new challenges for equipment manufacturers. A research team at the Fraunhofer Institute for Solar Energy System ISE has now succeeded in implementing a novel…

The manufacturing technique enables faster production, greater optical quality and design flexibility. Researchers at UC Berkeley have developed a new way to 3D-print glass microstructures that is faster and produces objects with higher optical quality, design flexibility and strength, according to a new study published in the April 15 issue of the journal Science. Working with scientists from the Albert Ludwig University of Freiburg, Germany, the researchers expanded the capabilities of a 3D-printing process they developed three years ago —…

THE University of Huddersfield has forged a partnership with an innovative technology business to work with Network Rail on developing a safer and more reliable track lubrication measurement system. The collaboration will allow the University’s award-winning Institute of Railway Research (IRR) to work with Sheffield-based small and medium enterprise (SME) Tribosonics Ltd to develop a novel solution to the problem of detecting whether a critical form of lubrication is present between a railway wheel and the track. In partnership with Network Rail and funded through its…