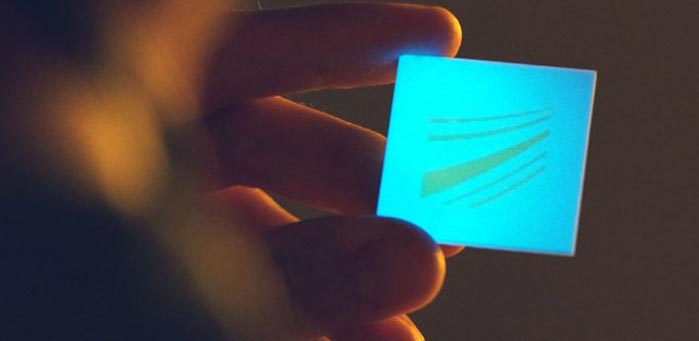

New technology kit enables extended functionalities. Fraunhofer ISIT operates state-of-the-art production lines for processing silicon with a processing accuracy in the nanometer range. These precise structure generation processes have now been successfully transferred to other materials. The shaping of various types of glass has proven to be particularly significant. After all, with the integration of optical functions into the world of microsystems, the packaging of components and systems at wafer level (WLP) is facing new challenges. Future applications, such as…

… for making miniature IR optics. New technique can create complex 3D optics for infrared spectroscopy, sensing and more. Researchers have developed a new fabrication process that allows infrared (IR) glass to be combined with another glass and formed into complex miniature shapes. The technique can be used to create complex infrared optics that could make IR imaging and sensing more broadly accessible. “Glass that transmits IR wavelengths is essential for many applications, including spectroscopy techniques used to identify various…

The development of resource-efficient manufacturing processes for next-generation battery anodes was the aim of the joint project „nextBatt“ funded by the German Federal Ministry of Education and Research (BMBF, funding reference: L1FHG42421). At the Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP, new material combinations and efficient production technologies have been realized for this purpose. The Institute will present recent results at SVC TechCon 2022, May 3 – 5 2022, in Long Beach/USA, at booth No. 436. The demand…

Glass objects which glow in the dark, glass containers that heat up and cool down, or glass control knobs and switches that eliminate viruses and bacteria by themselves – all this seems to completely contradict our everyday experience of what glass can do. And yet, it is now within reach. To create such functionalized and precision-molded glasses, research teams at Fraunhofer IKTS in Dresden have transferred their experience with ceramic processes to glass manufacturing. Thanks to the new shaping possibilities,…

Reduces friction and extends product life. Toyohashi University of Technology research team led by lecturer Toru Harigai have developed an ultra-high-rate coating technology for functional hard carbon films using vacuum plasma. Functional hard carbon films with low friction coefficients are used as protective films with sliding surfaces. This technology has achieved a film deposition rate of more than one order of magnitude faster than existing coating technologies, while maintaining the same degree of film quality. The technology—which can be introduced…

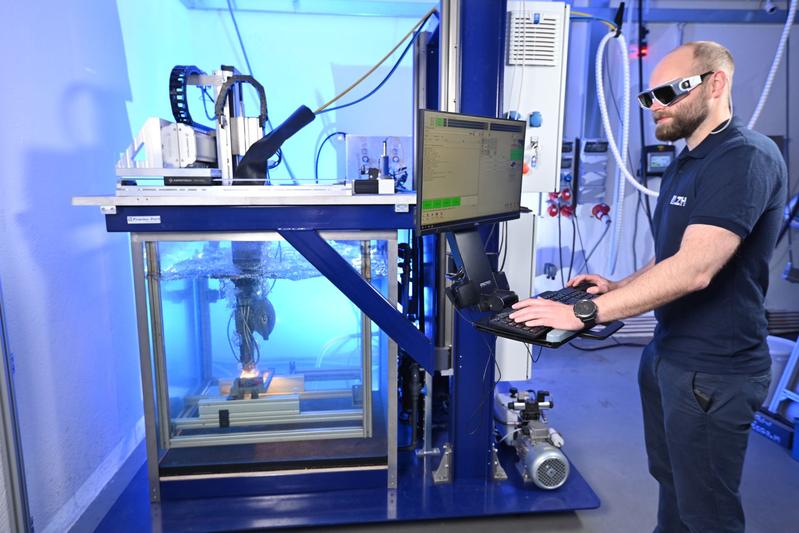

… for defusing explosive ordnance in the sea. Together with project partners, the LZH is developing a process to defuse world war ammunition under water using a laser. The goal: to affect the ecosystem as little as possible while saving time and costs. In the North and Baltic Sea, approximately 1.6 million tons of war ammunition lie on the seabed. The danger of unforeseen detonations is not the only problem. Over time, the water causes the steel shell of the…

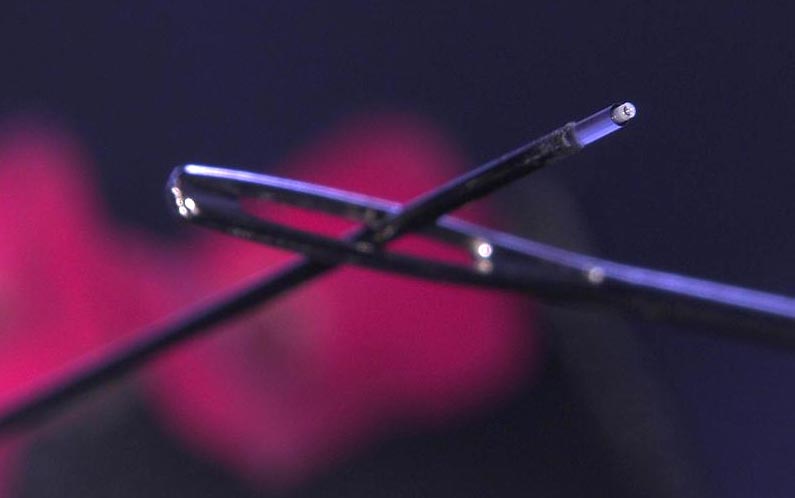

In the field of optogenetics, scientists investigate the activity of neurons in the brain using light. A team led by Prof. Dr. Ilka Diester and Dr. David Eriksson from the Optophysiology Laboratory at the University of Freiburg has developed a new method to simultaneously conduct laminar recordings, multifiber stimulations, 3D optogenetic stimulation, connectivity inference, and behavioral quantification on brains. Their results are presented in Nature Communications. “Our work paves the way for large-scale photo-recording and controlled interrogation of fast neural…

Researchers at Leipzig University have succeeded in moving tiny amounts of liquid at will by remotely heating water over a metal film with a laser. The currents generated in this way can be used to manipulate and even capture tiny objects. This will unlock groundbreaking new solutions for nanotechnology, the manipulation of liquids in systems in tiny spaces, or in the field of diagnostics, by making it possible to detect the smallest concentrations of substances with new types of sensor…

EucoLight, the European Association of collection and recycling organisations for Waste Electrical and Electronic Equipment (WEEE) lamps and lighting, has carried out successfully a study with Fraunhofer IZM on the technical feasibility for the automatic identification of lamp types in the collected lamps waste stream for recycling. The study focused on the technology assessment for the separation of collected End-of-Life (EoL) lamps, more specifically the technical possibilities for separating conventional gas discharge lamps (GDLs) from conventional light-emitting diode (LED) lamps….

Inspired by nature: Electro-biocatalytic CO2 fixing replaces fossil resources. Making important raw materials for fine chemicals out of carbon dioxide really works. As part of the Max Planck collaborative project eBioCO2n, a team of researchers from Fraunhofer IGB have successfully performed a first ever fixation of CO2 via a multi-enzyme enzyme reaction driven by electricity yielding a prospective intermediate for the chemical industry. The process for electro-biocatalytic CO2 fixation was recently published and is considered a “hot paper.” Burning fossil…

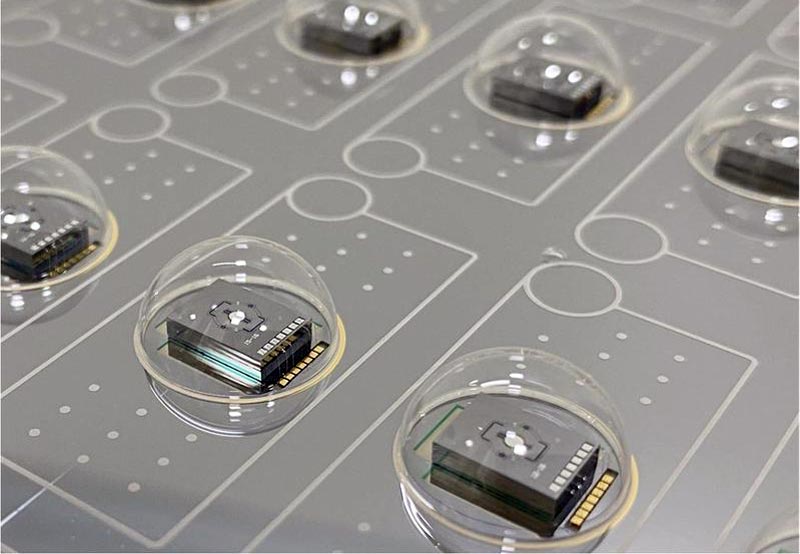

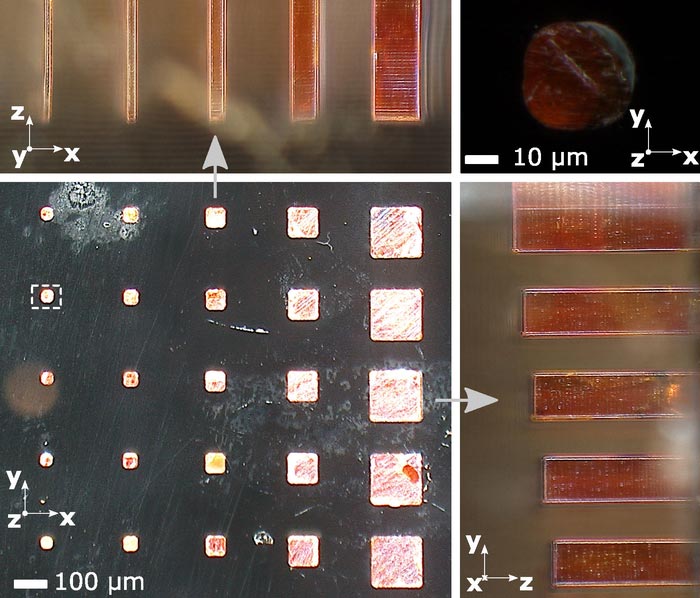

Successful spin-off: 3D printing offers completely new design and application possibilities in many areas. Scientists at the University of Stuttgart have been exploring and developing this flexible method for producing complex, miniaturized imaging systems using 3D multiphoton lithography. The inventors now want to use their knowledge to start-up an enterprise: Printoptix GmbH i.G. is currently being set up in order to grow its business as an independent limited liability company (GmbH) from next year onwards. 3D printing offers completely new…

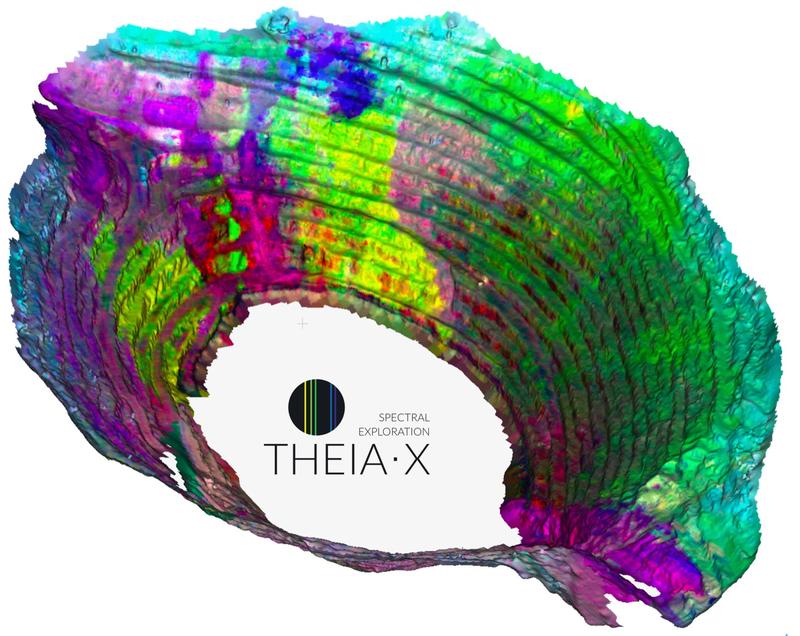

Freiberg-based start-up TheiaX enters market with innovative mapping methods. With the increasing demand for high-tech metals by the industry, mining faces complex challenges. The sustainable supply of raw materials requires energy-efficient and socially acceptable methods with low environmental impact. At the Helmholtz Institute Freiberg for Resource Technology (HIF) belonging to the Helmholtz-Zentrum Dresden-Rossendorf (HZDR), researchers have developed novel, digital mapping methods for sustainable raw material exploration and extraction over the past two years and brought them to market. The founding…

Researchers of the Cluster of Excellence 3D Matter Mode to Order show how 3-dimensional nanostructures can be printed using compact desktop devices – publication in Nature Photonics. Lasers in conventional laser printers for paper printouts are very small. 3D laser printers for 3-dimensional microstructures and nanostructures, by contrast, have required big and expensive laser systems so far. Researchers of Karlsruhe Institute of Technology (KIT) and the Heidelberg University now use another process for this purpose. Two-step absorption works with inexpensive…

New technology makes production of complex metallic objects at the nanoscale possible. In recent years 3D printing, also known as additive manufacturing, has established itself as a promising new manufacturing process for a wide variety of components. Dr Dmitry Momotenko, a chemist at the University of Oldenburg, has now succeeded in fabricating ultrasmall metal objects using a new 3D printing technique. In a paper published together with a team of researchers from ETH Zurich (Switzerland) and Nanyang Technological University (Singapore)…

Researchers at Texas A&M have fine-tuned the process for creating defect-free metal parts using a laser bed powder fusion 3D printing technique. In the last few decades, metal 3D printing has spearheaded the efforts in creating custom parts of intricate shapes and high functionality. But as additive manufacturers have included more alloys for their 3D printing needs, so have the challenges in creating uniform, defect-free parts. A new study by Texas A&M University researchers has further refined the process of…

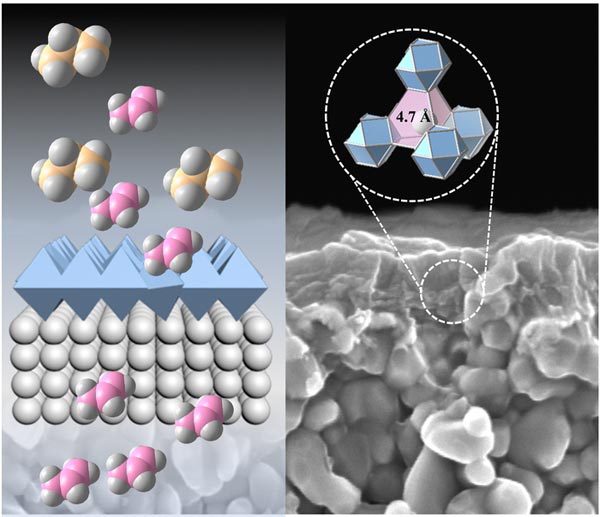

An electrochemical approach developed at KAUST produces molecular-sieving membranes that could enable a cheap energy-efficient separation of light hydrocarbons, such as olefins and paraffins. This separation, critical for the petrochemical industry, usually relies on extremely energy-intensive processes, such as distillation. Membrane-based strategies have emerged as promising alternatives to heat-driven separation approaches. Existing polymer-based membranes are not selective enough for hydrocarbon separation and also undergo plasticization, a structural change that alters their pores, at high pressure. On the other hand, highly…