A new method designs nanomaterials with less than 10-nanometer precision. It could pave the way for faster, more energy-efficient electronics. DTU and Graphene Flagship researchers have taken the art of patterning nanomaterials to the next level. Precise patterning of 2D materials is a route to computation and storage using 2D materials, which can deliver better performance and much lower power consumption than today’s technology. One of the most significant recent discoveries within physics and material technology is two-dimensional materials such…

Researchers at the University of Freiburg and the University of Stuttgart have developed a new process for producing movable, self-adjusting materials systems with standard 3D-printers. These systems can undergo complex shape changes, contracting and expanding under the influence of moisture in a pre-programmed manner. The scientists modeled their development based on the movement mechanisms of the climbing plant known as the air potato (Dioscorea bulbifera). With their new method, the team has produced its first prototype: a forearm brace that…

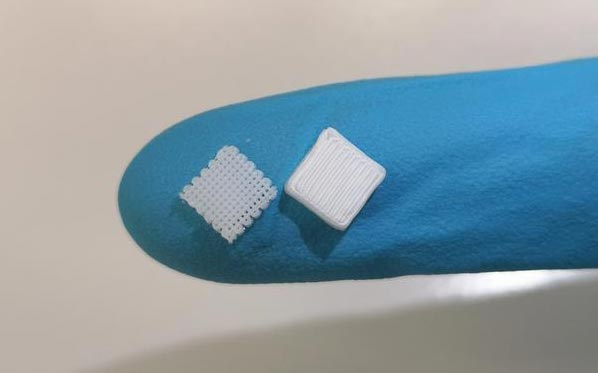

Braunschweig continues to expand its strengths in the manufacture of individualized pharmaceutical products. For this purpose, the Fraunhofer Institute for Surface Engineering and Thin Films IST and the Center of Pharmaceutical Engineering (PVZ) of the Technische Universität Braunschweig are cooperating for the first time. The Fraunhofer-Gesellschaft is providing 0.5 million euros to support the establishment of a translational laboratory for “Individualized Pharmaceutical Production” in Braunschweig as part of the new Lower Saxony High-Performance Center “Medical and Pharmaceutical Engineering”. A mutually…

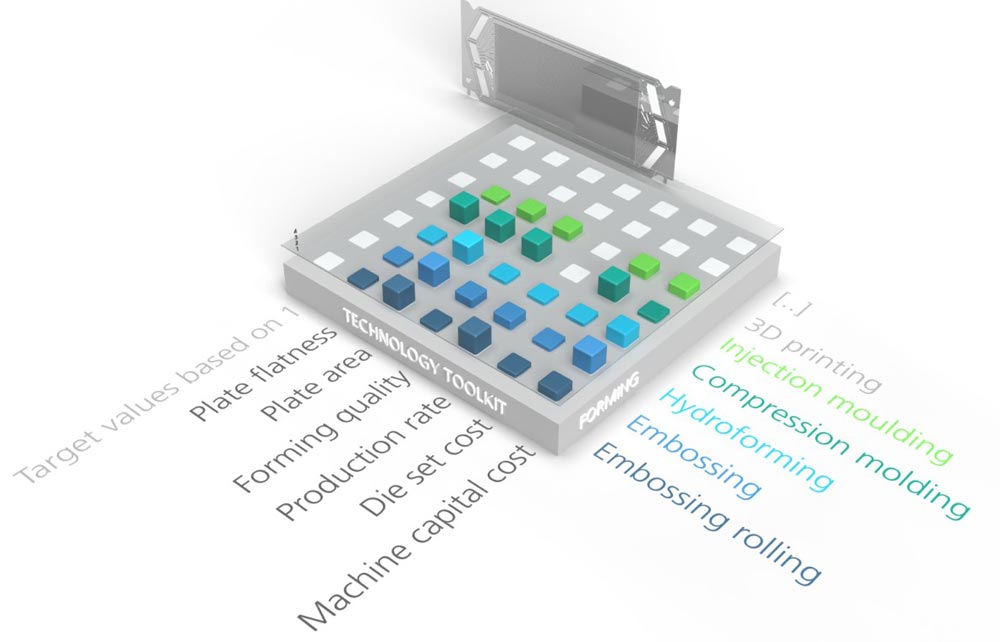

The ideal forming technology to suit any need: Decision-making tools for the industry. Fuel cells have huge potential, but there are not yet any clear structures and standards surrounding their manufacture. The huge number of options when it comes to production technologies makes it challenging for users or potential users to maintain an overview in their mind and to select the right production process to suit their needs. To help overcome this problem, researchers at the Fraunhofer IWU and the…

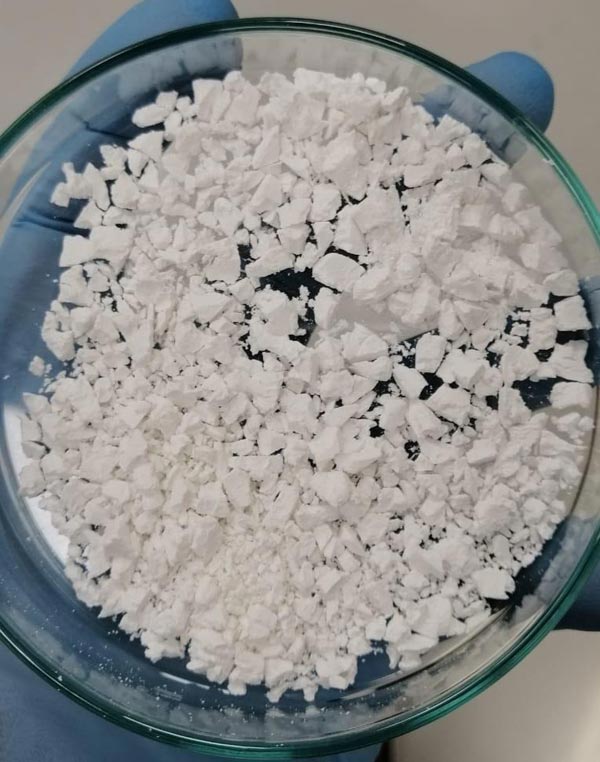

A sustainable circular economy … A significant part of carpet waste consists of petroleum-based polypropylene. As a non-recyclable product, disposing of it has previously meant incineration or landfill. However, a new solvent is now making it possible to recover virgin-standard polypropylene from carpet waste — with no perceptible reduction in quality. Developed by the Fraunhofer Institute for Building Physics IBP and its partners, the process also involves costs that are quite competitive. The development has taken place as part of…

unibz contributes to the fight against microplastics … In 2017, the UN declared the presence of 51 trillion microplastic particles in the Earth’s seas: “500 times more numerous than all the stars in our galaxy”. A product invented and patented by Marco Caniato, a researcher and lecturer at the Free University of Bozen-Bolzano, has proved extremely promising in the battle against the environmental dispersion of microplastics. Secondary microplastics, i.e. plastic fragments of less than 5 mm in size resulting from…

Researchers at UniSA have developed a cost-effective technique that could deliver safe drinking water to millions of vulnerable people using cheap, sustainable materials and sunlight. Less than 3 per cent of the world’s water is fresh, and due to the pressures of climate change, pollution, and shifting population patterns, in many areas this already scarce resource is becoming scarcer. Currently, 1.42 billion people – including 450 million children – live in areas of high, or extremely high, water vulnerability, and…

Innovative biotechnological process extracts gallium from industrial wastewater Gallium is a rare metal, but it is widely used in the high-tech industry. This extreme contrast makes recycling indispensable. However, current recycling processes are costly and chemically polluted. Biotechnological approaches, therefore, rely on peptides, as they are able to bind metallic particles, minerals and metal ions in an environmentally friendly manner and to differentiate them in a targeted manner. Scientists at the Helmholtz Institute Freiberg for Resource Technology (HIF) at the…

The Fraunhofer Institute for Laser Technology ILT’s globally successful EHLA extreme high-speed laser material deposition process is not only turning heads. In the collaborative project EVEREST, the institute – along with three industrial partners – has developed process and system technology to efficiently repair and coat components and tested it on rollers. Now after successfully completing the project, the Aachen researchers want to establish the newly developed process chain in the industry. The goal is to coat long and large…

Surface and coating technology Microscopy is at the forefront of the fight against the coronavirus. Special microscopes, which enable scientists to view minute cell structures, are an indispensable tool in the development of vaccines and new therapies. Such equipment comprises not only a microscope with high optical resolution but also a high-precision microscope stage. Hard-magnetic coatings from the Fraunhofer Institute for Surface Engineering and Thin Films IST also play a key role here. They help enable the examination of minuscule…

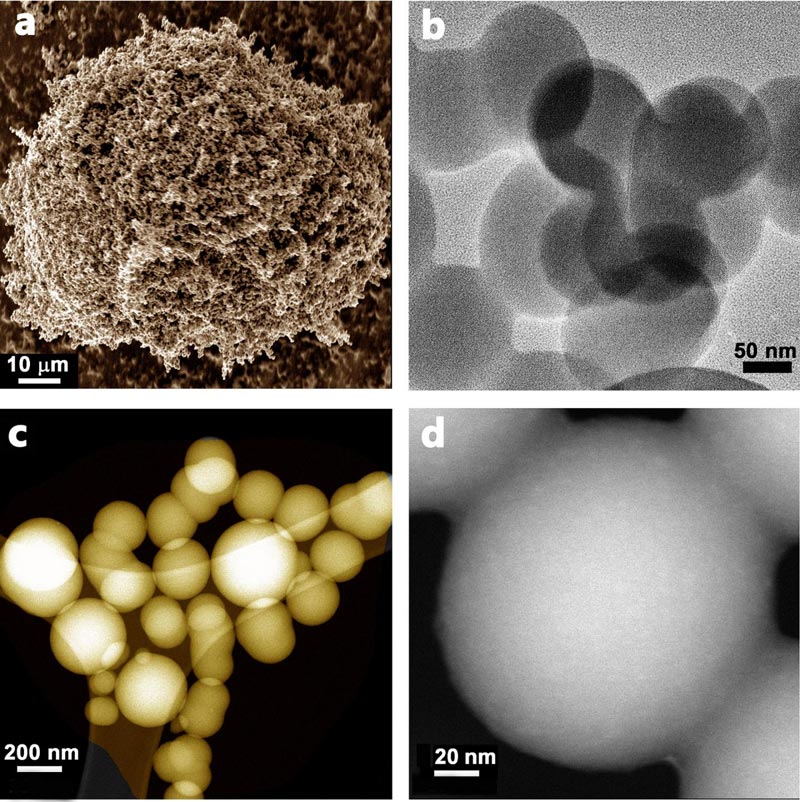

– advance could improve carbon capture technology A fast, green and one-step method for producing porous carbon spheres, which are a vital component for carbon capture technology and for new ways of storing renewable energy, has been developed by Swansea University researchers. The method produces spheres that have good capacity for carbon capture, and it works effectively at a large scale. Carbon spheres range in size from nanometers to micrometers. Over the past decade they have begun to play an…

Converting polyethylene packaging into high-value products incentivizes plastics recycling. While many cities and eight states have banned single-use plastics, bags and other polyethylene packaging still clog landfills and pollute rivers and oceans. One major problem with recycling polyethylene, which makes up one-third of all plastic production worldwide, is economic: Recycled bags end up in low-value products, such as decks and construction material, providing little incentive to reuse the waste. A new chemical process developed at the University of California, Berkeley,…

Chemists at Martin Luther University Halle-Wittenberg (MLU) have developed a way to integrate liquids directly into materials during the 3D printing process. This allows, for example, active medical agents to be incorporated into pharmaceutical products or luminous liquids to be integrated into materials, which allow monitoring of damage. The study was published in “Advanced Materials Technologies”. 3D printing is now widely used for a range of applications. Generally, however, the method is limited to materials which are liquefied through heat…

Sustainable processes could replace valuable metals in silicone crosslinking. Silicones are tried and tested in the private and professional domains. In many applications, however, expensive precious metals are required as catalysts to transform the liquid intermediate products to durable elastic polymers. A research team from the Technical University of Munich (TUM) and the Munich-based WACKER Group has now developed a curing process that works without precious metals. Silicones are synthetic polymers consisting of an inorganic silicon-oxygen backbone modified with organic…

After the summer harvest, fruits are sold as dried products suitable for the current season. However, if fruit or vegetables are dried with heat, nutrients can be destroyed and flavors can be reduced. This is why non-thermal drying of food – i.e. without heating – is preferred by the industry. Among other things, fans are used for this purpose. A new drying process developed at Empa using ionic wind promises to make the non-thermal drying of food much more energy-efficient,…

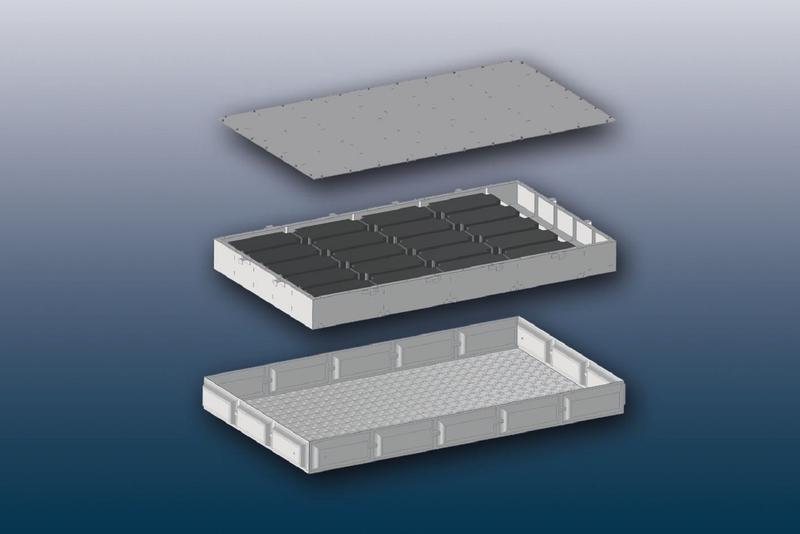

Martensitic chromium steels are one of the steel grades with a future, steels that are ideal for automotive applications since they are both lightweight and corrosion resistant. These materials are particularly in demand for the design of collision-safe battery boxes for electric cars. For this reason, the Fraunhofer Institute for Laser Technology ILT in Aachen uses these sophisticated components as demonstration components for laser welding and heat treatment. As part of the AiF research project FAAM, supported by FOSTA –…