The aim of the IMUcompact research project was to develop a unit that can track the position of autonomous drone systems with pinpoint accuracy. The inertial measurement unit (or IMU for short) at the heart of the system essentially uses three gyroscope axes and three acceleration sensors to establish a position in navigation uses or map terrain with centimeter-level precision, even without a GPS signal. Compact, low-resolution gyroscopes are now found in most smartphones and smartwatches, for example to determine the orientation of the screen or camera. Although these so-called MEMS gyroscopes are also small and lightweight, they are easily affected by environmental forces like changes in the temperature, humidity, or electromagnetic fields. This made them less suitable for use on drones, but IMU systems with higher resolutions used to be no feasible option for industry or commercial use due to their size and cost.

The interferometric fiber optic miniature gyroscope (IFOG) developed at Fraunhofer Institute for Reliability and Microintegration IZM enables a higher level of detail and can be fitted to a wide variety of carrier drones due to its compactness and low weight. As IFOGs contain no moving parts and are electromagnetically insensitive, they are far better suited for use in UAVs than conventional MEMS alternatives.

Exceptional miniaturization, courtesy of an innovative assembly method

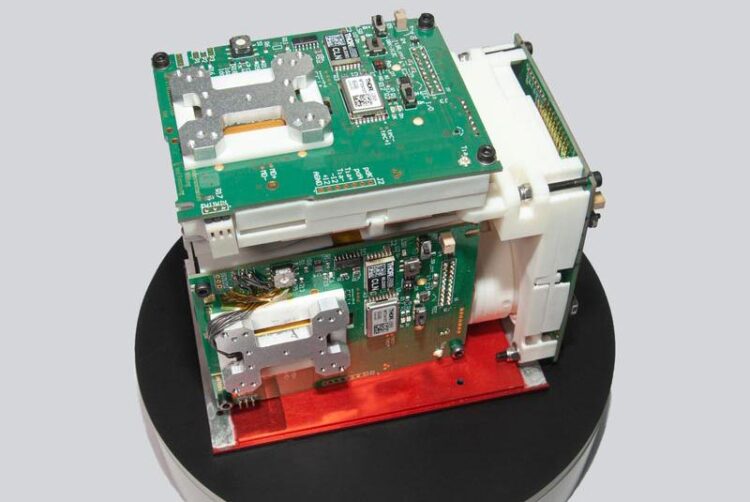

A novel assembly method was developed to make sure that the electronic and optical components of the IMU can be arranged in such a way that a high degree of miniaturization is achieved without compromising on accuracy. Conventional IMUs only have a resolution in the range of 25 to 30cm. By comparison, the gyroscope developed at Fraunhofer IZM now offers an absolute accuracy of less than 10cm. The special arrangement of the measuring components on a 3D-printed optical bench also gives it great mechanical strength for industrial applications, all while keeping the weight very low. In addition, the researchers developed an application-specific circuit board, with a robust and compact design.

Photogrammetric measurements from the air

One of the first practical applications of the new IMU is photogrammetry with UAVs. Photogrammetry is the technology for measuring and identifying physical objects using a combination of 2D images and 3D measurement methods such as LIDAR. In this case, the weight of the IMU must not exceed 5 kg. Possible applications for drone-based photogrammetry include the automated surveying of factory buildings, the technical monitoring of offshore wind turbines, or automated stocktaking in agriculture and livestock farming. Drone-based photogrammetry can also make an important contribution for damage assessments in disaster areas, especially when large areas are affected by unexpected environmental events. Providers of online mapping services also use photogrammetric methods to create digital 3D maps, although this often required the cost-intensive use of aircraft or gyrocopters with the necessary measurement technology on board.

Strong partnership between research and industry

“As experts in the assembly and interconnection technology of optical fibers, we were able to work with our project partners and develop a demonstrator that combined an IMU with a GPS system and a powerful integrated circuit to create a complete, integrated solution. The next step is to optimize this prototype in order to further advance the civilian use of autonomous drone systems,” project leader Dr. Alethea Vanessa Zamora Gómez and developer Christian Janeczka proudly summarize the end of the project. The IMU could be used in other carrier systems such as marine, aerial, or other autonomous vehicles and even AI-based logistics networks for even greater automation.

In addition to Fraunhofer IZM, the IMUcompact project included IGI – Ingenieur-Gesellschaft für Interfaces mbH, IntraNav GmbH, and MILAN Geoservice GmbH as associate partner. The project was funded by the Federal Ministry of Education and Research for a period of five years until March 2023 under funding code 13N14758.

Text: Yannic Walter

Wissenschaftliche Ansprechpartner:

Dr. Alethea Vanessa Zamora Gómez l phone +49 30 46403- 7995 l alethea.vanessa.zamora.gomez@izm.fraunhofer.de |

Fraunhofer Institute for Reliability and Microintegration IZM I Gustav-Meyer-Allee 25 | 13355 Berlin | www.izm.fraunhofer.de |

Originalpublikation:

https://www.izm.fraunhofer.de/en/news_events/tech_news/compact-navigation-system…