Ear implants with a memory

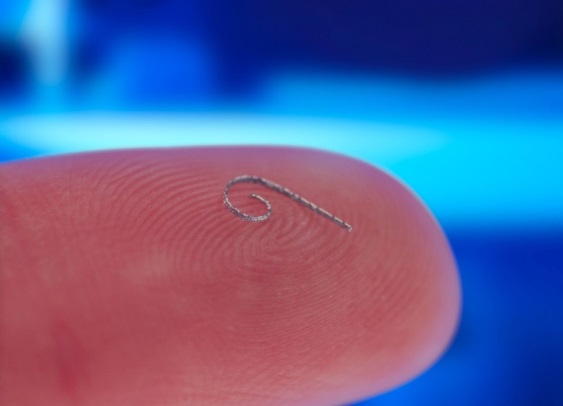

This laser-additive manufactured micro-actor for cochlea implants can change its shape due to temperature changes. Foto: LZH

The challenge, however, is to print highly precise and small prints which are, on top of that, made of difficult-to-process materials. The scientists at the Laser Zentrum Hannover e.V. (LZH) are conducting research on that very topic.

At the Hannover Messe 2014, they will demonstrate how they use the laser to manufacture tiny implants with a memory function or complex shapes, such as the cochlea of the human inner ear.

In the field of medical technology Laser Additive Manufacturing (LAM) opens up new ways of healing, e.g. for hearing-impaired persons. Inserting an implant into the tiny cochlea requires utmost care.

During the procedure the surgeon runs the risk of destroying intact sensory cells which would even further decrease the hearing ability of the patient.

The micrometer-small cochlea replicas that the surgeons use to practice the procedure are manufactured by the LZH’s Photonic System Technology Group using the LAM technology. The Surface Technology Group at LZH goes one step further.

In cooperation with the Hannover Medical School (MHH), they are developing implants that change their shape due to temperature changes during the surgery and shall thus make the insertion much easier.

Using printed Magnesium to reconstruct faces

LAM also allows for the manufacturing of temporary implants. These Magnesium scaffolds are slowly and gradually decomposed by the human body.

They are well suited for reconstructing defects of the facial skull, because their shape can be matched to the face of the patient. Directly after the surgery, the bioresorbable implants stabilize the tissue above. Afterwards, they make room for new bone cells.

Tiny, highly complex parts, however, not only inspire innovations in biomedical technology. There are practically no limits to their use. Polymers or metals, for example, can be used.

Even complex parts with internal openings can be manufactured rapidly and with high precision. Only a 3D drawing is required.

For more information about Laser Additive Manufacturing visit the LZH at the Hannover Messe: Lower Saxony Pavilion, hall 2, stand A08.

http://www.lzh.de/en/hannovermesse2014 – more information about LZH at the Hannover Messe

Media Contact

All latest news from the category: HANNOVER MESSE

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…