Several studies have already impressively demonstrated that beam shaping in laser powder bed fusion (LPBF) can improve the efficiency and productivity of this additive manufacturing process. The Fraunhofer Institute for Laser Technology ILT and the Chair of Technology of Optical Systems (TOS) at RWTH Aachen University are working together to create a state-of-the-art test system enabling them to flexibly investigate complex laser beam profiles in power classes up to 2 kW, an innovation that can be used to customize solutions for industrial partners. This platform is designed to integrate LPBF processes more efficiently and robustly into industrial production so that they can meet its growing demands.

Disadvantages of the Gaussian distribution

Currently, laser powers of around 300 to 400 watts are common in many LPBF processes. However, the standard Gaussian laser beam they use has significant disadvantages: The high concentration of power in the beam center leads to local overheating and undesirable material evaporation as well as process instability, both of which can impair component quality due to spatter and pores. These issues significantly limit the scalability of the process, meaning that the laser power available in LPBF systems – often up to 1 kW – cannot be utilized for most materials.

“One way to speed up the process is to use several lasers and optical systems in parallel,” says Marvin Kippels, PhD student in the Laser Powder Bed Fusion Department at Fraunhofer ILT. “However, the costs scale at least proportionally to the number of systems installed.” In addition, these systems cannot always be utilized homogeneously in real applications, which means that productivity cannot be increased proportional to the increase in power. A promising approach is, therefore, to increase the productivity of the single beam process, which can also be transferred to multi-beam systems.

New possibilities through beam shaping

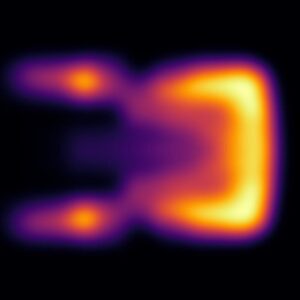

Previous studies have shown that even simple beam shapes with rectangular, ring-shaped or a combination of two Gaussian distributions produce promising results for both component quality and process speed. The potential of more complex beam shapes has so far been largely unexplored, as the necessary system technology was lacking. This is now changing thanks to the comprehensive investigations that researchers at Fraunhofer ILT have begun.

“The interaction of laser beam and material in the process is so complex due to its dynamics that simulations can only provide indications of the actual melt pool behavior,” explains Kippels, who is currently setting up a new type of system that uses LCoS-SLMs (Liquid Crystal on Silicon – Spatial Light Modulator), which will enable researchers to investigate almost any beam profile in the LPBF process.

As it has a laser power of up to 2 kW, the innovative system is a platform for testing new beam shapes at very high power levels in the LPBF process, which allows the suitable system technology to be identified for an individual LPBF task. “We can optimize the LPBF process in a targeted manner,” explains Kippels. He refers specifically to less material evaporation, less spatter formation, reduced melt pool dynamics, smoothened melt track surface, and increased process efficiency by adapting the melt track geometry.