MEMS microspeakers for the future of the mobile internet

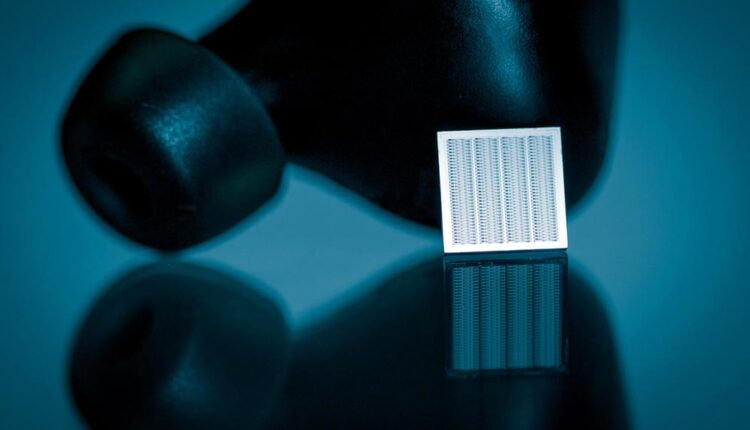

An Arioso Systems silicon microspeaker in front of a wireless in-ear headphone.

© Arioso Systems GmbH

The microspeakers for wireless in-ear headphones from Arioso Systems GmbH, a spin-off of the Fraunhofer Institute for Photonic Microsystems IPMS, are up to ten times smaller than conventional microspeakers and are made entirely from silicon. Currently at the prototype stage, the energy-efficient MEMS speakers may in future play a role in expanding the range of functions offered by miniaturized headphones – such as instant translations and health monitoring features. This is made possible by an innovative sound transducer principle that dispenses with the membrane, the central element of a conventional speaker.

Wireless in-ear headphones are on trend and are the perfect companion when you’re on the move. However, they are still relatively large and many of their components drain the battery quickly, restricting internet connectivity, payment functions and other smart features. New intelligent functions require lots of computing power and therefore lots of space and electricity. The speakers that are currently available are too large. The bulkiest components of newer, wireless earphones are the battery and microspeaker. By contrast, the microspeakers from Arioso Systems GmbH measure just 10 to 20 mm2, making them ideal for future hearables applications, such as simultaneous translation, payment functions and other voice-based internet services. The Dresden-based Fraunhofer IPMS spin-off was founded in 2019 and now has 12 employees.

Sound is generated inside the silicon chip

Unlike conventional speakers and the few other micro-electromechanical system (MEMS) speakers in existence, the tiny MEMS speakers from Arioso Systems do not contain a membrane or magnets, and instead are formed entirely from silicon. They can be mass-produced cost-effectively using standard CMOS processes, making them easy to scale for the mass market – an advantage over competitors’ technologies that currently use piezo materials which make the production process more complicated and expensive.

The speakers use a new, power-efficient sound transducer principle. This is based on Nanoscopic Electrostatic Drive (NED) technology, which was developed by Holger Conrad – a founding member of Arioso Systems GmbH – during his time at Fraunhofer IPMS. Unlike conventional speakers, the new MEMS sound transducer has no membrane. It has been replaced by a large number of thin bending beams, each measuring 20 μm, contained within the silicon chip. Through openings on the top and bottom of the chip air escapes from the chambers and flows into the chambers where electrostatic actuators move. The application of an audio signal voltage causes these NED actuators to bend. The vibrations are then heard as sound. “The lamella-like bending beams move toward each other and push the air out at the top and bottom, causing pressure fluctuations in the ear that are audible. In principle, the eardrum is moved directly like it would be with an air pump,” explains Arioso CFO Dr. Jan Blochwitz-Nimoth.

As the components can be integrated directly in the silicon chip, they take up little space and are much more energy-efficient than conventional speakers. The technology uses less battery, extending the battery life by several hours. “The sound is generated inside the silicon chip. The fact that there are no outer moving parts such as membranes frees up space and reduces the number of assembly steps in the production process,” states Arioso CEO Dr. Hermann Schenk, highlighting a USP of the MEMS speaker. “The thin lamellas inside the chip are moved by applying an electrical voltage. This generates a sound pressure level of around 120 dB with optimum sound quality over a chip area of just 10 mm².”

Alexa in your ear

In the future, it will be possible to use the space that is saved in the wireless headphones by the high degree of miniaturization and the energy efficiency of the MEMS speakers for other internet applications such as payment services or instant translations. It is also possible for users to monitor functions relating to their bodies – all via voice control, without them having to look at their smartphone. With this in mind, Arioso Systems GmbH is directing its development towards the needs of large OEMs and internet service providers in particular. The innovative sound transducer principle is also suitable for use in hearing aids.

The seed funding round has been closed and the spin-off has so far received 2.6 million euros from investors. Over the next two to three years, the prototype MEMS microspeakers are set to be scaled up from lab to pilot scale. Arioso Systems is already in discussions with investors for the next funding round, which is aiming to acquire venture capital of approx. 10 million euros. “We hold the exclusive marketing rights to the NED technology from Fraunhofer IPMS. Over the coming years, we are striving to become the market leaders in MEMS speaker technology for the mobile audio world,” states Dr. Hermann Schenk, explaining the ambitious objective of the company.

Weitere Informationen:

https://www.fraunhofer.de/en/press/research-news/2021/december-2021/mems-microsp…

Media Contact

All latest news from the category: Information Technology

Here you can find a summary of innovations in the fields of information and data processing and up-to-date developments on IT equipment and hardware.

This area covers topics such as IT services, IT architectures, IT management and telecommunications.

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…