Software tool finds ’needles’ in data ’haystacks’

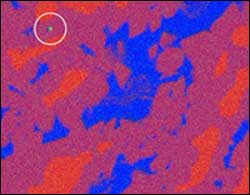

X-ray data collected with a scanning electron microscope from a nickel-aluminum alloy. Pure aluminum is represented by blue, pure nickel by red and nickel-aluminum alloys by colors in between. The green dot in the upper left shows a contaminant particle of chromium identified with the NIST software that occupied only one pixel of the microscope’s scanning area. The sample measures about 160 micrometers across. Image credit: D. Bright, D. Newbury/NIST

When looking for a needle in a haystack, it’s helpful to know what a needle looks like. A new software tool developed by researchers at the National Institute of Standards and Technology (NIST) makes it possible to find chemical ’needles’ in data ’haystacks’ without having to know anything about the ’needle’ in advance.

The NIST software should be especially useful for analyzing ultrapure metals–recently shown to have superior strength, corrosion-resistance and other properties–and for monitoring nanoscale semiconductor fabrication. Commercial X-ray detector manufacturers already have included the method used in the software into their products.

Described in the November issue of the Journal of Microscopy*, the software works with scanning electron microscopes (SEMs) and improves the analysis of X-ray data. SEMs raster a beam of electrons across a sample and then detect X-rays emitted in response. X-rays of specific energies (the equivalent of colors for visible light) are emitted by specific elements, making SEMs an excellent tool for mapping the chemical composition of samples. The lateral and depth resolutions of SEM/X-ray analysis range from 100 nanometers to 5 micrometers, depending on specimen composition and SEM beam energy.

Newer detectors—some developed with NIST funding—respond so fast that data across the entire spectrum of X-ray energies can be recorded for every pixel scanned. Typically, these data are analyzed to show only the sample’s major constituents. The NIST software analyzes the data a step further by identifying the X-ray energy with the highest intensity for each pixel rather than for the sample as a whole. Using the software with a nickel-aluminum sample, the NIST researchers identified chromium and copper contaminant particles that occupied just a single pixel and were not “visible” with the SEM’s usual data interpretation tools.

Media Contact

More Information:

http://www.nist.govAll latest news from the category: Information Technology

Here you can find a summary of innovations in the fields of information and data processing and up-to-date developments on IT equipment and hardware.

This area covers topics such as IT services, IT architectures, IT management and telecommunications.

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…