Sensor Film for Aerospace

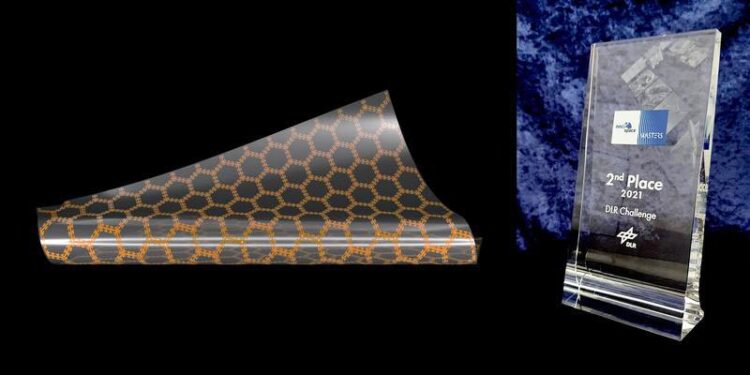

Model of the sensor film for measuring the material load of air and space vehicles in flight. On the right, the trophy with which this idea was awarded.

Credit: Alexander Hilgarth / University of Wuerzburg

Using a sensor film to monitor how well aircraft and spacecraft withstand the mechanical stresses of flight: Würzburg researchers have received a prize for this idea, which comes with a lot of money.

There is great joy at the Chair of Aerospace Information Technology: Alexander Hilgarth and Professor Sergio Montenegro were successful in the international INNOspace Masters competition.

They won second prize with their idea for a sensor film that can be applied to the components of aerospace vehicles and is monitoring them during flight. The award is linked to funding of up to 400,000 euros.

The researchers from Julius-Maximilians-Universität (JMU) Würzburg in Bavaria, Germany, want to use the money to make the sensor film ready for its first application. They have shown in preliminary studies that their idea basically works. The follow-up work will start in late autumn 2021 and should be completed after two years.

What are the benefits of such a film?

The sensor film can ultimately reduce maintenance costs in aerospace and make the reusability of space vehicles more likely, explains electrical engineer Hilgarth: “Only the reusability of carrier systems and components ensures the economic viability of being able to operate space travel in the sense of the ‘New Space’. However, the possible cost savings are currently still limited by high maintenance costs.”

The buzzword New Space describes the trend that private companies are also developing space activities. For example, the company SpaceX of the American entrepreneur Elon Musk. At the end of 2020, it used a space capsule on behalf of NASA to bring astronauts first to the International Space Station ISS and then back to Earth months later.

In addition, the sensor film can detect material defects that only occur under mechanical stress but remain hidden during inspections in the hangar. “One example of this are cracks whose fracture edges rejoin perfectly when unloaded,” says Hilgarth. Such defects have been observed in composite materials made of plastics, for example.

Film interconnects a wireless sensor network

Currently, it is not practical to monitor aircraft and spacecraft in flight with a comprehensive installation of measuring probes. “Conventional measurement technology is too big and too heavy for that,” explains the JMU electrical engineer. This could change with the TOMOPLEX (“Tomographic Plexus”) sensor film from Würzburg: it should enable continuous real-time monitoring.

The film uses tomographic measuring methods that are not yet common in aerospace. It functions as a circuit carrier for a wireless sensor network. According to the JMU researchers, it is space-saving and flexible. It can also be attached to hard-to-reach places on aircraft and spacecraft.

Facts about the competition

This time, the INNOspace Masters Challenge was held under the motto “Innovations for Sustainable Infrastructures – in Space and on Earth”. It was aimed at smaller companies, start-ups, universities and non-university research institutions from all over the world. A total of 330 teams from 23 countries submitted 126 ideas. In the end, a total of 15 ideas were awarded in five categories. The prizes were awarded at an online conference on 29 July 2021.

The competition was held for the sixth time. The organiser is the German Space Agency at the German Aerospace Center (DLR) on behalf of the Federal Ministry for Economic Affairs and Energy. The competition is part of the INNOspace initiative, which has been promoting innovations and technology transfers between space and non-space industries since 2013.

Success for the second time

Sergio Montenegro’s team has already been successful in the INNOspace Masters Challenge once before: in 2016, it won first place in the overall competition – with an idea for the wireless small satellite SKITH (Skip the Harness). This resulted in the INNOcube project, in which Montenegro’s team is working together with TU Braunschweig to bring a wireless small satellite into orbit. The launch is planned for 2023.

Wissenschaftliche Ansprechpartner:

Dipl.-Ing. Alexander Hilgarth, Chair of Computer Science VIII (Aerospace Information Technology), University of Würzburg, T +49 931 31-83924, alexander.hilgarth@uni-wuerzburg.de

Prof. Dr. Sergio Montenegro, Head of the Chair of Computer Science VIII (Aerospace Information Technology), University of Würzburg, sergio.montenegro@uni-wuerzburg.de

Weitere Informationen:

https://innospace-masters.de/tomoplex-a-sensor-film-to-monitor-structures-during… DLR press release on the competition

Media Contact

All latest news from the category: Information Technology

Here you can find a summary of innovations in the fields of information and data processing and up-to-date developments on IT equipment and hardware.

This area covers topics such as IT services, IT architectures, IT management and telecommunications.

Newest articles

Innovative 3D printed scaffolds offer new hope for bone healing

Researchers at the Institute for Bioengineering of Catalonia have developed novel 3D printed PLA-CaP scaffolds that promote blood vessel formation, ensuring better healing and regeneration of bone tissue. Bone is…

The surprising role of gut infection in Alzheimer’s disease

ASU- and Banner Alzheimer’s Institute-led study implicates link between a common virus and the disease, which travels from the gut to the brain and may be a target for antiviral…

Molecular gardening: New enzymes discovered for protein modification pruning

How deubiquitinases USP53 and USP54 cleave long polyubiquitin chains and how the former is linked to liver disease in children. Deubiquitinases (DUBs) are enzymes used by cells to trim protein…