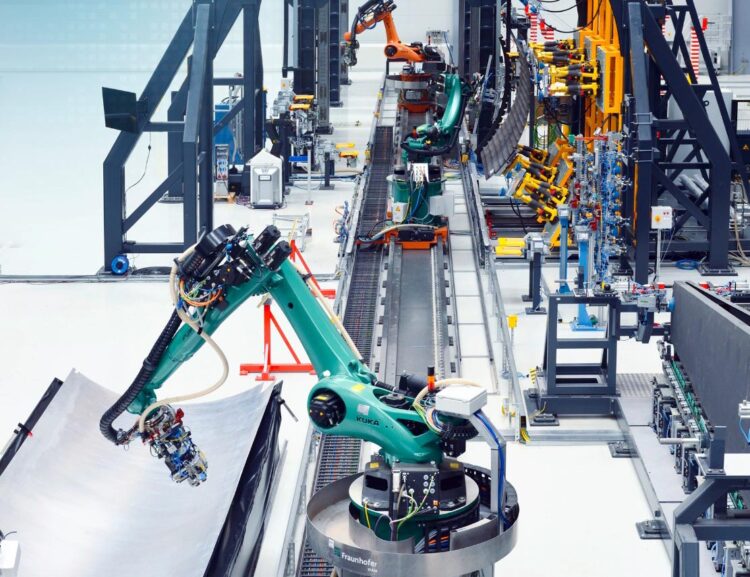

Automated machining and assembly of large lightweight structures for rail vehicle construction

Large-scale structure assembly on a 1:1 scale in the 4500 m2 research hall with a height of 15 m at Fraunhofer IFAM in Stade, Germany

© Fraunhofer IFAM

Automation solutions on a 1:1 scale for sustainable rail vehicle construction from Fraunhofer IFAM in Stade, Germany – InnoTrans 2022.

InnoTrans 2022 l Hall 23 l Booth 240 l The Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM in Stade will be presenting automation solutions on a 1:1 scale for sustainable rail vehicle construction for the first time as part of the leading International Trade Fair for Transport Technology from September 20 to 23, 2022 in Berlin, Germany.

Research and development activities focus on new weight-saving materials and manufacturing processes that not only increase efficiency and decrease costs in production, but also reduce energy consumption in operation, which in turn saves costs and supports climate protection.

The current challenge in large-scale structural assembly, which is relevant for rail vehicle construction, is to reconcile efficiency, sustainability and ergonomic workplace design. The experts for automation and production technology address this issue and provide insights into current application-oriented R&D results in the context of automated assembly, including machining and joining processes.

The 4500 m2 research hall with a height of 15 m of Fraunhofer IFAM at the Research Center CFK NORD in Stade provides many large-scale research facilities which can be used flexibly and are equipped with robots, holding fixtures, and high-performance measurement technology. This makes it possible to relieve customers of the “upscaling” involved in the direct transfer of research results to their production, because Fraunhofer IFAM – with regard to process and plant development – can validate the step from the laboratory into a production-analog environment with real components on a 1:1 scale on the institute’s own premises.

Automated large-scale structure assembly

In order to combine efficiency, sustainability, and ergonomic workplace design in large-scale structure assembly, Fraunhofer IFAM is developing mutually compatible technology modules which – depending on the intended use – can be combined in a modular way to create partially or fully automated assembly solutions including production logistics, robotics, measurement, positioning, machining, and joining processes.

The focus is on flexibility and ease of operation as well as continuous digital data flow in the sense of “plug-and-produce”. R&D activities are centered on large components made of lightweight materials on a 1:1 scale, for which the entire process chain up to the fully assembled large structure can be designed and simulated after part production.

Important for sustainability is the consistent saving of resources through accelerating and parallelization of process steps up to the optimization of the process chain as well as by increasing process quality. The timely consideration of assembly requirements in the design also significantly increases manufacturing efficiency.

Mobile lightweight robotics and service robotics

In addition to research into industrial robotics, Fraunhofer IFAM in Stade is also expanding its expertise in the field of mobile lightweight robotics for logistics, application, and assembly tasks. Thus, a steadily growing share of the R&D activities comprises the development of assistance systems with comparable requirements. The modular system components enable technology transfer to other areas such as service robotics.

Representative in this regard is the development of an autonomously navigating cleaning and disinfection robot for use in public transportation (PT; www.ifam.fraunhofer.de/en/Press_Releases/mobile-cleaning-and-disinfection-robot.html; https://s.fhg.de/FuEMobDiStade; Video).

This service robot can not only be seen live in action at the Fraunhofer booth (Hall 23 l Booth 240), but also inside the “IdeasTrain” of S-Bahn Hamburg l Deutsche Bahn (outdoor area T11 l 60).

More information:

http://www.ifam.fraunhofer.de/en/Events/innotrans-2022.html InnoTrans 2022

http://www.ifam.fraunhofer.de/en/stade Website

https://s.fhg.de/7wp Flyer Automation and Production Technology

Media Contact

All latest news from the category: Machine Engineering

Machine engineering is one of Germany’s key industries. The importance of this segment has led to the creation of new university degree programs in fields such as production and logistics, process engineering, vehicle/automotive engineering, production engineering and aerospace engineering among others.

innovations-report offers informative reports and articles covering technologies such as automation, motion, power train, energy, conveyor, plastics, lightweight construction, logistics/warehousing, measurement systems, machine tools and control engineering.

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…