Finding natural resources in the deep sea with the laser

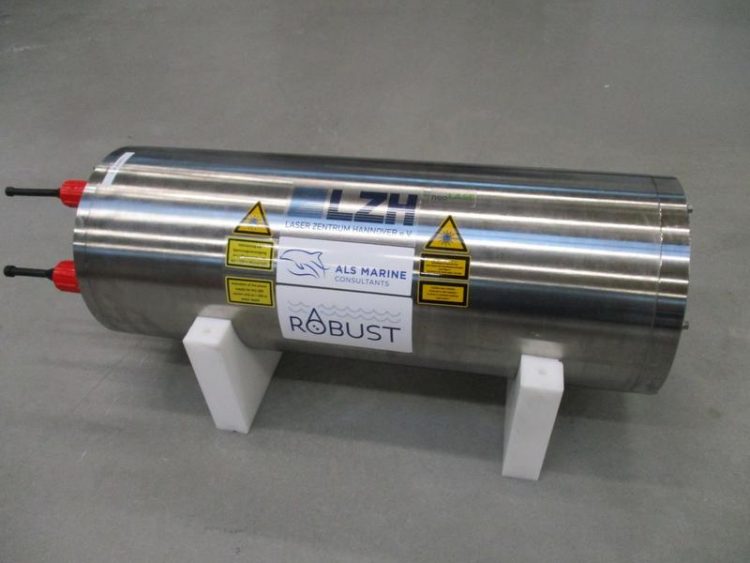

The LIBS system developed by the LZH in a pressure housing from ALS Marine Consultants for use in a water depth of 6000 m (600 bar). Photo: LZH

The system for laser-induced breakdown spectroscopy (LIBS) makes it possible to examine material samples for their atomic composition almost non-destructively.

The LIBS system developed by the LZH successfully withstood a pressure of 400 bar in practical tests in the deep sea. Lasers, controls and software worked perfectly.

The experiments were carried out during a research trip in the Pacific on the research ship SONNE of the Federal Ministry of Education and Research.

On the ROV Kiel 6000 diving robot from the GEOMAR Helmholtz Center for Ocean Research Kiel, the LIBS system dived to the bottom of the sea.

Successful analysis under high pressure and in cloudy waters

The LIBS system was able to detect copper and zinc in real massive sulfide samples at up to 500 bar. The measurements under deep sea conditions took place at the company Nautilus in Buxtehude.

During a research trip in the Baltic Sea on GEOMAR's Littorina research ship, the system was able to reliably detect copper and zinc in the prepared samples even in relatively cloudy water.

These are promising bases for further experiments under real conditions in the deep sea.

About LIBS

LIBS is a non-contact and almost non-destructive method for the analysis of chemical elements. Solids, liquids and gases can be examined with it. The method is based on the generation and analysis of a laser-induced plasma. Here, a high-energy laser beam is focused on the sample. The energy of the laser beam at the focal point is so great that a plasma is created. The plasma in turn emits element-specific radiation, which is measured with a spectroscope. The emission lines in the spectrum can be assigned to the chemical elements of the sample.

About ROBUST

The project “Robotic Subsea Exploration Technologies – ROBUST” (grant number: 690416) is funded by the European Union within the scope of the program “Horizon 2020”.

https://www.lzh.de/en/publications/pressreleases/2020/robust press release with an animation

Media Contact

All latest news from the category: Machine Engineering

Machine engineering is one of Germany’s key industries. The importance of this segment has led to the creation of new university degree programs in fields such as production and logistics, process engineering, vehicle/automotive engineering, production engineering and aerospace engineering among others.

innovations-report offers informative reports and articles covering technologies such as automation, motion, power train, energy, conveyor, plastics, lightweight construction, logistics/warehousing, measurement systems, machine tools and control engineering.

Newest articles

First-of-its-kind study uses remote sensing to monitor plastic debris in rivers and lakes

Remote sensing creates a cost-effective solution to monitoring plastic pollution. A first-of-its-kind study from researchers at the University of Minnesota Twin Cities shows how remote sensing can help monitor and…

Laser-based artificial neuron mimics nerve cell functions at lightning speed

With a processing speed a billion times faster than nature, chip-based laser neuron could help advance AI tasks such as pattern recognition and sequence prediction. Researchers have developed a laser-based…

Optimising the processing of plastic waste

Just one look in the yellow bin reveals a colourful jumble of different types of plastic. However, the purer and more uniform plastic waste is, the easier it is to…