Fraunhofer IWM closes gaps in the mechanics of materials digital value chain

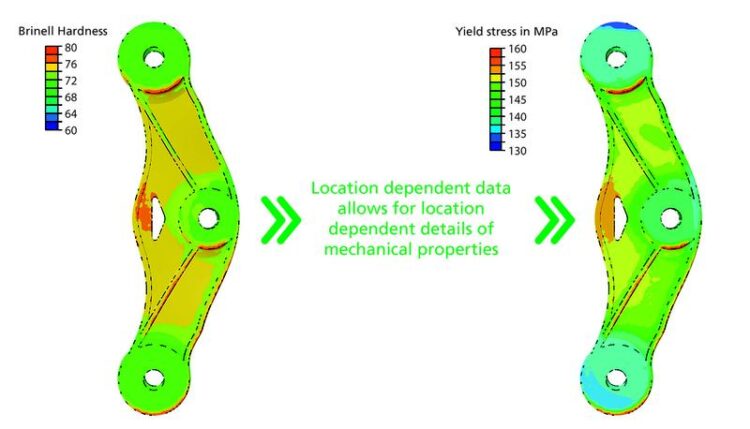

The digital twin of a demonstrator casting contains the Brinell hardness determined on an experimental basis (left). It enriches the numerical simulation of the yield stress with location-dependent data (right)

© Fraunhofer Institute for Mechanics of Materials IWM

The greatest potential of digitalization in companies in which materials play a prominent role lies in the cross-process linking of materials data. This promises to shorten component development times, faster optimization of complex manufacturing processes and more reliable plant operation. The problem is the very heterogeneous nature of materials data, which makes linking within this data extremely complex. The research project MaterialDigital of the state of Baden-Württemberg under the leadership of the Fraunhofer Institute for Mechanics of Materials IWM in Freiburg has now made great progress in structuring materials data into a continuous data space.

Not only is there great potential for digitalization in materials technology, but the challenges are also considerable. »Due to their complexity, materials data are extremely heterogeneous and also change continuously during the product life cycle,« says Dr. Christoph Schweizer from the Fraunhofer Institute for Mechanics of Materials IWM, describing the difficulties. »The fact that they vary locally within a product and in some cases cannot be determined non-destructively via measurement technology makes their structuring, storage and linking quite demanding.«

The industry therefore faces considerable challenges: how do we gather all the data together in a meaningful way? What infrastructure do we need to accomplish this? Where do we begin with the integration of a data space? Dr. Christoph Schweizer is now providing answers to these questions together with a consortium of seven research institutions that joined forces in the »MaterialDigital« research project in 2018. The Baden-Württemberg Ministry of Economics, Labor and Housing provided 2.75 million euros in funding for the project.

Pioneering work for the materials data space

Based on two use cases, the partners were able to show how companies can digitalize their material-intensive processes in order to achieve a continuous and machine-readable data space. The application case coordinated by the Fraunhofer IWM concerned the gravity die casting of aluminum parts, as used for example in the automotive industry and in mechanical engineering. For this purpose, they developed the necessary basic principles such as software tools for structuring the data and automating the workflows, and based on these, they created an exemplary material data space. In addition, the partners also provided evidence that digital value-added chains provide substantial benefit. With the help of real material and process data, the participating researchers were able to use a digital twin to handle more complex simulations and at the same time more precisely predict component properties.

»Based on data space queries, quick and precise decisions can be made in companies in which materials play a prominent role instead of having to go through expensive and time-consuming trial and error loops,« says Dr. Christoph Schweizer, the overall project coordinator. »Our data space architecture is designed in such a way that it can be easily transferred to other material processes.« Tools and workflows are thus available to potentially interested industries who can adapt them to their specific needs. The materials data structured in the project use case of the aluminum casting process will be published by the consortium as a best practice example for scientific re-use.

Research potential in decentralization and AI

For Dr. Christoph Schweizer, an internal Fraunhofer program based on the national project MaterialDigital began immediately after the national project, with which the data space technology is to become decentralized and ready for use. »Further research potential of the materials data space lies in particular in integrable logics and the exploitation of machine learning,« says the business unit manager for Assessment of Materials and Lifetime Concepts. Specially designed computer models could be used to read out and make use of laws not yet stored in the process graphs. This would allow far more specific predictions to be made while the modeling steps could be drastically minimized.

Details concerning the materials data space technology

The central concern of the consortium was to develop the technical foundations and workflows for the materials data space based on established standard formats. The Fraunhofer IWM was particularly in demand here with its expertise in data handling. »In developing a uniform data structure for material-intensive processes, we had to start practically from scratch, because there was virtually no preparatory work,« explains Dr. Christoph Schweizer.

The basis of each data space is an ontology, i.e. a common language, which ensures that all data can be clearly classified. In the state project, the participants used ready-made basic ontologies to supplement the particularly broad technical vocabulary used in materials technology. They then correlated the data within the data space with the aid of a knowledge graph that logically links data. Well-known examples of the use of knowledge graphs are the info boxes that Google presents via the simple links of a search result. If, for example, a user searches for capital cities, the local weather or cinema programs, Google displays matching images and explanations in a gray box above the actual search results.

An app which translates process graphs into an Excel template

With the help of this basic structure of ontology and knowledge graph, the researchers were initially able to describe individual process steps of the use cases, the so-called »process modeling«. In the next step, the individual processes were connected to each other according to their chronological sequence in the real process chain to form a virtual network. In this final materials data space, not only are the process descriptions and their metadata available, but the raw data can as well be accessed automatically via links, so that a variety of evaluations are possible.

So that laypersons can also fill the data space with data, the scientists of the project programmed an app with which the modeled process graphs can be automatically fully converted into an Excel template. This file can be filled by hand if necessary and thus does not require any previous knowledge of data spaces.

Successful improvement in the casting process.

Schweizer and his colleagues proved that this structured and comprehensively linked knowledge base brings real added value by integrating experimental data and simulations. For a cast part, they thus created a digital twin that exploits the relationship between the locally different solidification during casting and the locally varying hardness to build up a simulation model with heterogeneously distributed mechanical properties. Using insights from the data space, the simulation model can additionally be fed with precisely selected material parameters that take into account the casting specific chemical composition and heat treatment.

Based on the digital twin, the researchers were able to predict the functional mechanical properties of the casting demonstrably more precisely than with batch-independent material parameters. This was done much faster and with less effort than with previous methods.

Institutes involved in the project:

• Fraunhofer-Institut für Werkstoffmechanik IWM

• Fraunhofer-Institut für Chemische Technologie ICT

• Fraunhofer-Institut für Physikalische Messtechnik IPM

• FZI Forschungszentrum Informatik

• Institute of Textile Technology and Process Engineering DITF

• Naturwissenschaftliches und Medizinisches Institut NMI

• Forschungsinstitut Edelmetalle + Metallchemie fem

Infobox: Digitalization in Baden-Württemberg

Mechanical engineering in Baden-Württemberg is going digital: a business survey conducted by the German Engineering Federation (VDMA) Baden-Württemberg shows that mechanical engineering companies see the digital transformation as necessary to secure the future of their business. For the survey, 236 companies from the mechanical engineering sector in Baden-Württemberg were interviewed.

The companies hope that the digitization measures implemented will bring about positive changes in terms of productivity and competitiveness. For example, 53.6 percent of the companies surveyed stated that they want to gain an advantage over their competitors through the digital transformation. Nearly three-quarters of the companies want to increase productivity with the help of new technologies. Which measures are to be used in the course of digitalization is already being discussed. Just under a third of the companies surveyed (30.7 percent) are concerned with the benefits of the digital twin, and over half (57.1 percent) with digital condition monitoring or predictive maintenance.

Wissenschaftliche Ansprechpartner:

Dr. Christoph Schweizer, Phone +49 761 5142-382, christoph.schweizer@iwm.fraunhofer.de

Media Contact

All latest news from the category: Machine Engineering

Machine engineering is one of Germany’s key industries. The importance of this segment has led to the creation of new university degree programs in fields such as production and logistics, process engineering, vehicle/automotive engineering, production engineering and aerospace engineering among others.

innovations-report offers informative reports and articles covering technologies such as automation, motion, power train, energy, conveyor, plastics, lightweight construction, logistics/warehousing, measurement systems, machine tools and control engineering.

Newest articles

Decoding Cancer: 40 Years of Breakthroughs in Genetic Research

Cancer in children and adolescents is rare. Nevertheless, malignant diseases are still one of the most common causes of death in this age group. Survivors of childhood or adolescent cancer…

Let’s Think Before the First Drink: How Early Substance Use Might Lead to Brain Structure Differences Among Adolescents

Many differences appeared to exist prior to any substance use, pointing to the role brain structure may play in substance use risk, NIH-supported study suggests. Studies reveal factors that expose…

Combating Kidney Cancer Using Enhanced Immunotherapies

Medical University of South Carolina Hollings Cancer Center researcher receives Department of Defense Early Career Scholar Award to improve immune therapies by targeting resistant kidney tumors. A Medical University of…