PC Game Technology Helps Developers of Machines

Depending on the task involved, the new Mechatronics Concept Designer reduces development time by up to 20 percent. The solution makes it possible for all specialist departments to develop a machine together right from the start instead of successively, as has been the case until now.

The Mechatronics Concept Designer is the first development tool of its kind for conceptualizing complex machines. The program was presented recently at the PLM Europe trade fair in Linz, Austria.

The design tool is a big leap forward in particular for manufacturers of machine tools. Such machines produce work pieces from a predefined material, which they grind, stamp or mill, for example. The complex, program-controlled facilities perform a great many work steps, and experts in mechanics, electronics and control software take part in their development.

Today, a concept for a new machine is usually sketched out with paper and pencil, and the sketch serves as the basis for building a mechanical model. This is when the information for the electrical design first becomes available – for example how many sensors, actuators or electric motors are needed.

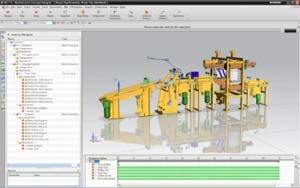

With the Mechatronics Concept Designer, however, all the specialists work together to develop a virtual machine — including all the motors, sensors or actuators — and thus generate data structures with which the work in each discipline can be immediately continued. The program is based on interactive games software and simulates the machine’s behavior in real time in a three-dimensional model.

As in a computer game, the user can intervene in a simulation that is in progress. Once created, the objects can be deposited in a library, complete with all their mechatronic data — for example a gripper with its geometry, movements, sensors and motors. The process saves not only development time; it also boosts the quality of the unit because it enables the use of components that have already been validated. And it also makes it easier and faster to perform subsequent modifications.

The Mechatronics Concept Designer was developed by Siemens Industry’s PLM Software (Product Lifecycle Management) division and features open interfaces for interaction with tools from Industry Automation and Drive Technologies.

Media Contact

More Information:

http://www.siemens.com/innovationnewsAll latest news from the category: Machine Engineering

Machine engineering is one of Germany’s key industries. The importance of this segment has led to the creation of new university degree programs in fields such as production and logistics, process engineering, vehicle/automotive engineering, production engineering and aerospace engineering among others.

innovations-report offers informative reports and articles covering technologies such as automation, motion, power train, energy, conveyor, plastics, lightweight construction, logistics/warehousing, measurement systems, machine tools and control engineering.

Newest articles

Innovative 3D printed scaffolds offer new hope for bone healing

Researchers at the Institute for Bioengineering of Catalonia have developed novel 3D printed PLA-CaP scaffolds that promote blood vessel formation, ensuring better healing and regeneration of bone tissue. Bone is…

The surprising role of gut infection in Alzheimer’s disease

ASU- and Banner Alzheimer’s Institute-led study implicates link between a common virus and the disease, which travels from the gut to the brain and may be a target for antiviral…

Molecular gardening: New enzymes discovered for protein modification pruning

How deubiquitinases USP53 and USP54 cleave long polyubiquitin chains and how the former is linked to liver disease in children. Deubiquitinases (DUBs) are enzymes used by cells to trim protein…